-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2571

As the world's largest arms dealer, Lockheed & middot; Martin company is more famous in the field of innovation from its subordinate R & D Organization: "skunk works". The factory has built many well-known air force weapons, such as U2 reconnaissance aircraft, the first stealth fighter F-117 and the first fifth generation fighter F-22. Its masterpiece in recent years is the fifth generation fighter F35, which can be applied to the three services of sea, land and air, greatly reducing the complex maintenance costs. "Skunk factory" has always been famous for its innovative management mechanism, which can quickly organize the production of products to meet the urgent needs of the country, so as to become a model student of global manufacturing innovation.

In August 2021, it expressed its determination to create another benchmark for arms manufacturing in an unusual way. The goal this time is to have the same speed as a cheetah and the same cost as a pheasant.

An unusual opening ceremony

On August 10, the skunk factory in Palm Valley, California held a grand commencement ceremony to show the construction of advanced manufacturing facilities. It has invited people from all sides and widely publicized it, which is unusual for a world's most secret and advanced weapons manufacturer.

This is one of the four digital transformation manufacturing plants that Loma will open in the United States this year, namely "intelligent flexible factory IFF", with a total investment of nearly $400 million.

This 65000 square meter intelligent flexible factory IFF is prepared for 450 employees. The biggest feature is that it has powerful digital facilities to realize intelligent manufacturing, so as to support the weapons manufacturing of the U.S. military in a fast and economical way.

It is a rare moment for outsiders to really enter this mysterious building. Previously, the skunk factory has been trying to fundamentally reshape itself in the past. Starting from the original and unique prototype, at this moment, it has finally officially entered a production stage.

Loma tried to show that after a long preparation stage, the most disruptive journey of digital transformation began to officially start.

This time, site 10 of plant 42 of skunk factory is open to the public. This new building integrates three key priorities of Loma's advanced manufacturing: intelligent flexible factory (IFF); Technology enabled advanced manufacturing environment and flexible workshop.

Intelligent flexible factory IFF is the latest concept proposed by Loma. It is a principle of digital priority. It can simplify production and maximize flexibility through virtual connection equipment. The framework is an edge computing platform, which can realize the inheritance, expansion and standardized device connection of various IT platforms. In July this year, in a building near NASA's Kennedy Space Center, Loma opened the "Star center" digital chemical plant to assemble the Orion spacecraft in preparation for landing on the moon. Loma bought the training building and spent $20 million to transform it into a digital factory. The same goal is to deliver spacecraft at an unprecedented speed.

More than 30 machines in the "Star center" are connected to NASA related equipment and instruments, and are connected to Loma's intelligent flexible factory. Team members of both organizations can access valuable data in real time, including intelligent tools such as device monitoring, alarm and virtual reality.

Loma has deployed this plant framework in seven locations and is expanding throughout the company. The skunk factory is just the latest landing site.

This time, its external display can be divided into two dimensions. The first dimension is fresh and unique. It depicts how a digital factory works through digital engineering and digital manufacturing. The virtual digital space has officially become two sides of a factory coin. Pure physical plant space is no longer a complete world. In fact, more accurately, the physical plant in the second dimension is just the materialization of digital chemical plant. As predicted in the match of immortals, the imaginary seven fairies became the people Dong Yong saw under the old locust tree. In other words, the soul and body are finally separated at this moment, and the body is just a carrier. The most valuable innovation has been debugged repeatedly in the digital space. The on-site factory operation is more like completing a task download. In other words, it is like downloading a machine document on the cloud to the local, then opening the compressed package and installing it locally.

Skunk factory had many similar projects to verify digital manufacturing. Now, all the sub projects are finally finished, and all the moves and military spectrum are finally condensed in this new factory.

Moving towards agility is a goal that has been repeatedly emphasized.

Workshop or art space?

The plant was built on the original site of the hangar, which was the L-1011 project in the 1960s. I have been idle there since 2016, and there seems to be no movement on the outside. Even Google maps are like a big cement patch. Construction began in 2019 to transform into a digital chemical plant, and now it is finally completed. Inside the building, everything looks strange, just like entering the IKEA exhibition hall.

IKEA? Build a plane?

Yes, that's the idea of the skunk's new factory. The idea of skunk factory is that the assembly process of IKEA model can be copied in the aircraft manufacturing process to realize the assembly of high-performance aircraft.

In the new factory, a section of colorful glass floor entrance triggered people's love for Loma's iconic five stars. The ceiling of the factory is covered with silver shiny stripes, echoing the space of black paint. Next to it is a leisurely factory coffee for Machinists and engineers to enjoy at any time.

The design of the lobby is so important to the overall theme of the story. When each staff member enters the workshop, it is like approaching a story.

This seems to deviate from the early style of the skunk factory. Johnson, the earliest founder of the skunk factory, always emphasized not to use gorgeous and expensive buildings. Being very practical is the first principle. His biggest concern is that, like the general contractor, if customers of the Ministry of defense see gorgeous buildings, they will think that the factory is spending money indiscriminately.

Now Lockheed seems to have stopped worrying about this problem. There must be a good workspace to stimulate employees' creativity - this is the reason why skunk management can be loud and even proud. Who said that drinking coffee and playing billiards should only be the patent of employees of Silicon Valley companies like Google.

Obviously, the idea of the management of the skunk factory now deviates greatly from the way of doing things in the early skunk factory.

This sharp contrast inevitably reminds people that the factory in people's mind needs to be dissolved and reborn. Like an axe that needs to be melted and then recast into a sword. As the second factory besides the physical factory, digital virtual factory has become the opposite. If you really look at it, it is still just an engineering creation. What about the awareness of managers? When a colorful, gorgeous and Limited modern factory space clearly bid farewell to the old rigid machine workshop, the management thought and organizational structure are also undergoing fundamental changes.

Managers, are you ready?

Beyond manufacturing optimization, advanced digital revolution

The technology used in the new "future factory" (named building 648) includes stealth fighter, UAV, hypersonic missile and other advanced weapons and equipment. However, what is more noteworthy is that the core of the larger transformation being carried out inside the factory may completely change the development and production of very advanced aerospace concepts. This industrial capability may become more and more important for the U.S. military to maintain its competitive advantage.

The way of doing things has changed. In the whole enterprise, Loma began to transform almost all work in the business, from demand preparation, contract management, design and manufacturing technology, and on-site operation and maintenance. This is uniformly called "Loma's digital transformation."

Over the years, "skunk factory" has had to spend a lot of time and resources to establish workspace for various new projects in its pamdale park. These spaces often need to be frequently configured. Each hangar of plant 10 has to provide isolation areas and build special areas with chain fences. Moreover, some customized special tools are constantly purchased to realize prototype manufacturing.

Loma's goal in the new plant is to greatly improve the degree of automation by improving the flexibility of robots. It is worth mentioning that electroimpact, a robotics company dedicated to the U.S. Department of defense. It is responsible for the automatic wire laying of carbon fiber and can layer ultra-thin carbon fiber. This is a great progress for carbon fiber composites, which can make spatial structures into extremely complex shapes. This kind of lone ranger rarely seen in the Jianghu does not need to look for the global market. Just staying in the arms of American arms dealers is enough to be popular and spicy. This is a rare industrial form in the global manufacturing industry. They shine like mold in a cave in a dark corner where people are rarely seen.

But at the Loma plant, electroimpact's robots have other things to do, that is bolt riveting. Four robots work together to realize bolt connection and automatic drilling. They can drill holes in various materials (including composites and titanium) and realize fixed connection with bolts.

"Skunk factory" is not the first time to use these robots. Its ability has been demonstrated on the test platform of NASA's x-59a silent supersonic space shuttle. The electroimpact robot drilled more than 7500 holes on the x-59a, one every 21 seconds.

Drilling is no small matter. Abnormal drilling will increase the cost. For stealth aircraft, this kind of error is even more fatal because it will affect radar wave absorption. In the past, in order to ensure accuracy, these were often realized by manual manufacturing, just like knocking in the aircraft manufacturing workshop.

However, the manual era is over, and robots do everything. At present, the defect rate of drilling is less than 0.3%, and the uniformity of parts can be ensured. The speed of the cheetah is not from the cheetah, but from the robot.

Potential of redesigning the plant

In addition to being able to drill and fix quickly, the electroimpact robot can also perform work autonomously through programming. Its brain is no longer limited by specific tasks, and its legs and feet are beginning to be liberated. Because it is movable, the flexibility of the work area is greatly enhanced. The application of augmented reality allows employees to shuttle freely between virtual space and physical space. Workshop staff can check the physical components being built and immediately compare them with the digital model. If there is a problem, you can use AR or VR to explore potential repair solutions without having to assemble or disassemble the whole part first. This scheme will be returned to the designer synchronously. This scene was shown in the short video of the future of work released by Loma company in July 2018, and now it has landed.

The assembly line workshop will usher in a new flexible space. In this category, the machine is no longer bound to a specific project, and people can quickly switch to another project with the help of digital tools. This is the real flexibility. In the past, the long machine configuration time was almost short circuited. Correspondingly, the whole working area has a very modular feeling. On the floor of this new factory, nothing will be permanently nailed to the ground.

If a housewife likes to adjust the style of her room every few months, her idea is no different from Loma's attitude towards the factory workshop. More allies, and the designers of IKEA exhibition hall.

In fact, Tesla's Musk has already begun to explore the limits of the factory. As the top art optimized for hundreds of years, the automobile assembly line is considered to leave the factory very fast, but musk is completely indifferent to the beat speed of 0.2 meters per second. "Design the factory with the idea of designing products, regard the factory as an integrated system, and optimize the functions to the greatest extent by using the basic principles of physics". When he said this, musk was like a physical scientist. The design of the automobile factory is just an optimization of a physical formula. Tesla's factories are generally designed according to the principle of super factory and super production. For example, the battery factory near the Las Vegas Casino in Nevada is the largest single building in the world. The three-dimensional view of the Nevada battery factory is completely digitized, just like the details in the computer system. The coordination of all departments is carefully designed to avoid excessive consumption. There are no walls in the office space between the engineer and the mechanic; Both of them operate in the field side by side through handheld pad. From that corner of the factory, there is almost no difference between various types of work. From the factory optimization formula, each employee is just a variable. The essence of super factory is to optimize the basic physical formula to release the maximum potential. "Big" is only a superficial result, and frugality and efficiency are the top priorities. Cheetah speed and pheasant cost are the new Bible of manufacturing. This time, the skunk factory heard Musk's voice.

Contrary to the traditional perception of confidentiality, there will be Wi Fi inside the new factory. Although the "skunk factory" is often engaged in the highest secret projects of the U.S. government, about 85% of the work is classified. In fact, this is the first time that a contractor of the U.S. Department of defense has used wireless networks. The benefit is that data can be sent to the workshop more easily and flexibly. This is very necessary for the mobile robot of "skunk factory" to realize the seamless switching of stations under different projects. The entire infrastructure, including the network, must also be flexible. Because it is used for digital infrastructure, coupled with flexible Internet of things and intelligent manufacturing technology, it can mass produce multiple different weapon platforms at the same time. The plant allows free reconfiguration to achieve efficient and flexible manufacturing. It will not be designed specifically for the production of specific products (such as 140 F-35 fighters per year) like Loma's plant in Texas. This subverts the concept of most factories.

Serial processes have become a thing of the past, and parallel work is the mainstream. The cooperation between people and man-machine becomes more efficient because it eliminates data waste. As for stations, which flexible stations?

No, no, maybe there's no fixed station at all.

One ring after another, a serial lock for digital transformation

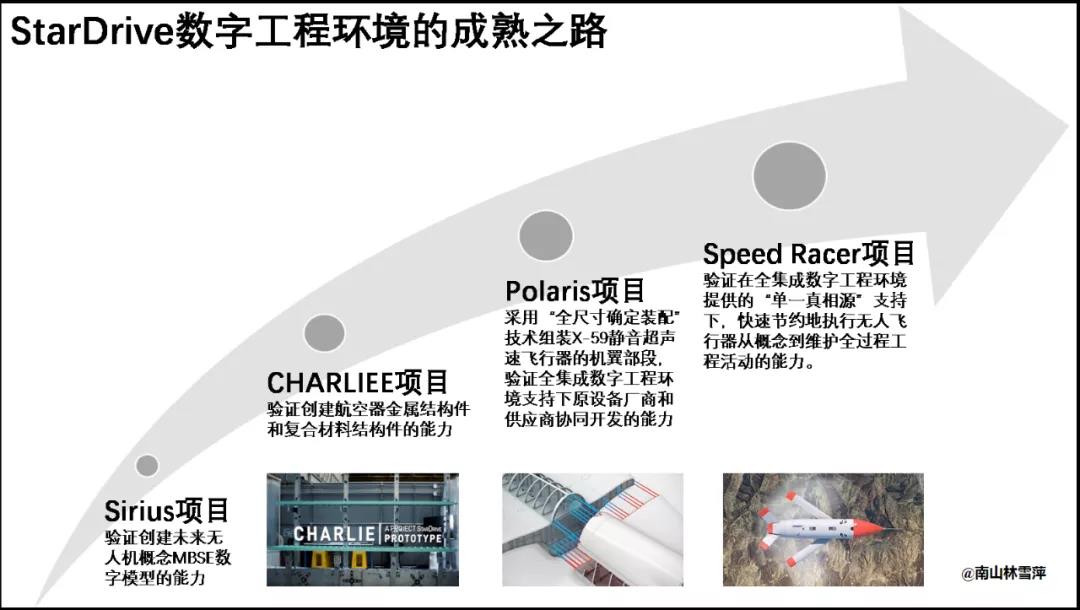

Loma's broad strategic ambition of "digital transformation" is not achieved overnight. It was achieved by developing a digital modeling and engineering tool set called stardrive. This is also due to the "skunk factory" based on rapid prototyping and high fidelity modeling capabilities for many years.

In the area visited on site, the whole has been divided, and only some local things can be seen. Because NASA's hypersonic x-59 is one of the few unclassified projects built by the skunk factory. The manufacturing process of x-59 has become the best springboard for Loma stardrive digital engineering, which can be used to continuously test new manufacturing processes.

Interstellar drive is a series of dazzling sub projects detonated in turn. Now, Loma has reason to be excited that "star driven" has transitioned from an experimental digital engineering project to a practical engineering process. These will be implemented in the new factory and will be highly confidential.

Fig. project evolution of Digital Engineering

A sub project of interstellar drive is the Sirius project, a digital model of model-based systems engineering mbse, which is used to realize tailless delta wing fighter type aircraft. This is the most important engineering concept for the future of American advanced manufacturing. It enables digital manufacturing to faithfully restore the design details in the minds of aircraft designers.

Most importantly, this accurate reproduction is not on paper, but in digital space. Therefore, it can be shared with important suppliers. The supplier's machines and environmental control systems can be combined with the main engine factory, even if they are thousands of kilometers apart. When the supplier's parts enter the Palm Valley factory, the tolerance fit can reach one thousandth of an inch. This is what stealth fighters and high-performance aircraft need.

If Sirius only established a model to prove that the plan is feasible. Subsequently, the project was further inherited to a new "Charlie project" to solve the specific physical connection problem. Start with metal to realize the assembly of aircraft wings. The result of the Charlie project is to successfully combine a metal wing and sub components, and successfully complete the matching between the physical components of the metal structure and the digital model.

Next, the matching of composites, which is the most difficult step. For digital manufacturing and deterministic assembly, metal materials are relatively easy to achieve. Composite materials are often affected by temperature difference, which is the key step.

This leap was realized on a follow-up project "Polaris", and it was loaded with guns. Because this time, collaboration in the supply chain has been realized. Skunk factory subcontracted part of the x-59 fuselage to spirit aviation systems. Half of them are completed respectively. Spirit, as a primary supplier, joined Loma's integrated digital environment IDE and used the stardrive tool. On this platform, spirit's components can conduct multiple "virtual running in" in the digital space. Finally, it can easily connect the composite structure to the metal frame. This process involves about 1500 fasteners and usually takes several hours. Now, only 30 minutes.

Finally, the time to hold your breath came, and the wings produced by two different manufacturers were assembled together. Only a few minutes, no machine flashing, no correction signal, no post-processing. This is a practical project with rapid progress. It proves that for any large advanced aircraft manufacturing project, the supplier can develop the substructure with the same tolerance and quality as the main engine factory. Employees of both parties can work together under the same real data source and in the same real-time environment, synchronously obtain design updates, task status and feedback information, and realize a single data source in all achievements, including CAD, system engineering and project progress data.

Digital twins are also advancing simultaneously. The star driven project manager of "skunk factory" has indicated in June that it will promote the digital twin data model on the mature platform of F-16 fighter to further reduce costs.

With toolset, digital twin model and various combined validation projects, stardrive digital engineering project has achieved great success, which makes it officially enter the stage of real plant engineering.

A chicken and an egg, synchronous newborn

However, the story is not over. Because this new digital project has proved to be successful, it has also created a newborn. A new product of digital project: Speed Racer.

"Speed Racer" was first displayed in September 2020. But a year later, it has greatly evolved.

"Speed Racer" was originally used as a small UAV similar to a missile. It is only used to demonstrate whether the new stardrive process is feasible. In the Sirius project, robot and automatic process can be realized, and component level connection can be realized. Furthermore, in the "Charlie" and "Polaris" projects, such an aircraft was also built at the same time. In fact, in order to simplify the difficulty of engineering manufacturing, the complexity of this product is also simplified. It is not a traditional aircraft, but a missile in order to simplify the manufacturing difficulty. This "Speed Racer" sample is just to prove that a weapon can be manufactured in large quantities and cheaply. The name "Speed Racer" itself is an abbreviation, representing "economical, compact, extended range, small penetrating and consumable bait". Unexpectedly, it has also achieved great success, and the subsequent versions can be put into practice. AFRL has shown strong interest and is likely to place an order.

Why is the air force interested? Because the air force command can use it as a cheap missile bait or a cheap cruise missile. It may use a cooperative tactic of swarm operation, true and false, to consume the opponent's anti missile fire. AFRL has begun to try to implement the production of speed racers through a series of plans, and the development site will also be in the skunk factory.

Establishing the digital twin of time series

Skunk factory is also strengthening international cooperation and making full use of artificial intelligence technology. It is working with NEC of Japan to use the latter's system measurement and analysis technology SIAT's artificial intelligence technology. Previously, the cooperation between the two has been used in NASA's Artemis mission and other projects. It can be said that in the whole space field, Loma is applying artificial intelligence technology to provide active insight in the requirements of production and operation tasks.

In recent years, Loma and NEC have been working together to evaluate the effectiveness of SIAT in early production test and operation scenarios, and have integrated this technology into Loma's general artificial intelligence telemetry and Analysis Technology (t-tauri) artificial intelligence service. Because it establishes a digital twin based on time series, Loma can actively detect anomalies in the design, development, production and test stages of spacecraft development - even before its application in mission operation.

NEC's SIAT advanced analysis engine uses data collected from sensors to learn the behavior of the system, including computer systems, power plants, factories and buildings, so that the system itself can automatically detect schemes inconsistent with regulations. By integrating Lockheed Martin's t-tauri platform, which is a comprehensive time series analysis framework, the team can obtain a detailed and comprehensive understanding of the system and create a basic system for other advanced technologies (such as system level digital twins). Since NEC established the initial partnership with Loma, the team has accelerated software regression testing to find production abnormalities as soon as possible.

High speed manufacturing for next generation air combat

With such a large open scale and such rapid digital engineering, Loma also hopes to grab more food in the large project ngad (next generation air dominance program) of the U.S. air force, such as future vertical elevators, supersonic aircraft, etc. Loma needs to prove that it can complete these high-performance advanced aerospace products in a new way, rather than the traditional aircraft, which takes 30-40 years to complete. Since the 1980s, the development of a new fighter takes decades to move an aircraft from a piece of paper to a factory workshop. Now, the development time of a new aircraft may be reduced to only five to eight years.

In recent years, the U.S. Department of defense has been talking about ways to subvert the aircraft development cycle and achieve a rapid iteration speed similar to that in the automotive industry. They believe that the traditional development process is too slow to keep up with potential competitors in ability. In 2019, the assistant secretary of the US Air Force first described a fast and iterative design concept, which is called "digital Century Series", relying on digital engineering technology and focusing on small batch production. The new factory of "skunk factory" is the faithful executor of this radical idea.

To do this, Loma must completely change the traditional way. Compared with its competitor Boeing, the latter is in a more leading position: Boeing has been demonstrating the capability of the latest advanced trainer t-7a (with a total value of $9.2 billion). However, due to the epidemic, Boeing t7a is also 7-9 months behind, and international suppliers, especially Saab in Sweden, which is responsible for assembly, are also lagging behind. The rear section and front section, wing and tail of t-7a advanced trainer are almost all produced by Saab, and the American factory is responsible for the final assembly. Due to the advanced digital production line, the wing and fuselage can be spliced in only 30 minutes. Digital technology has become the core competitiveness of aircraft manufacturers.

On the whole, Boeing, a military and civilian amphibious company, can establish digital technology advantages and obtain better cost advantages based on the practice of commercial aircraft. Because cost has always been the absolute driving force of commercial products. Lockheed and Northrop, on the other hand, could not benefit from this profound commercialization background. This also makes Loma's digital transformation more powerful. Digital transformation with huge investment can reduce the dilemma of high cost caused by lack of commercial practice.

Of course, even if Loma does not have Boeing's business experience, it can share common supplier experience. Spirit, for example, also participated in nogroup's stealth fighter b-21 program. It is also Boeing's largest commercial supplier - in fact, it used to be part of Boeing.

With the completion of the new plant this time, Loma also has a real opportunity to show to the outside world. They can have those big contracts for the air force. The digital transformation is the treasure of Luoma.

Although the volume of aviation parts is huge, the shape is fine and complex, and there are very expensive materials, the ultimate goal of aircraft manufacturing is to keep up with the automobile manufacturing industry. With the help of digital technology, the mechanization of aircraft manufacturing is realized. Adopt highly automatic and modular assembly mode. Significantly reduce manufacturing costs and accelerate time to market. The next generation fighter, air early warning aircraft, or the next generation tanker do not need to wait 20 years.

American aircraft manufacturers are vigorously promoting this to the military and the general public.

Notes: new taste of digitization

How to define such an innovative rise? Perhaps this is the new digital taste of arms manufacturers: faster and cheaper weapons: aircraft, missiles and spacecraft. The completion of the new factory means that the innovation know-how of the "skunk factory" has entered the era of "digital transformation". Although the new workshop has not been filled, the virtual space has already been filled with digital experience. These experiences, data and ideas have formed a fierce chemical reaction, while the physical reaction is slowly unfolding and landing one by one.

Digital transformation has become the biggest opportunity. The most complex aircraft design and manufacturing has been pressed the multiple speed fast forward key.

Digital from beginning to end, manufacturing craftsmen will cooperate with digital tools, and automation will be deepened. Robots, artificial intelligence and augmented reality are nested with each other, reducing redundant operations and greatly improving the mechanical experience to promote rapid innovation, which is a symbol of the "skunk factory".

(part of the material is referred to the WeChat official account of China's "air defense defense" and "aerospace defense observation"). Thanks to Mr. Chen Zhihong, China's Electrical Engineering Department, Yin Peng Yan and Liu Yawei of China Aviation Industry Development Research Center.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853