-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2036

[editor's note: Mercator, a German think tank, is one of the most active institutions in Germany to study China Affairs. Many German enterprises get their judgments on China issues from here. Mercator's comprehensive comments on the digital platform economy, especially on the industrial Internet, are worth thinking about. Nanshan Institute of technology compiled the report , in order to understand the views of the Germans, the contents are abridged.]

Figure 1 Mercator Report

outline

Digital platform economy will shape China's industrial future. China plans to become a superpower of scientific and technological innovation in 2049. A central project in this regard is the digitization of industrial production. In the manufacturing industry, building a digital platform is an important prerequisite for improving productivity, optimizing resource allocation and creating employment.

Other countries with a strong industrial base and rich experience in the field of "industry 4.0", especially Germany, can benefit from China's vitality. German companies such as Siemens, sap and Bosch have participated in China's emerging digital industrial platform branches. However, European participants must also be prepared for challenges. After Europe has so far lagged behind the United States and China in many areas of digitization, it is trying to play a leading role in industrial digitization.

China is investing heavily in the fourth industrial revolution

China is investing a lot of resources to lead the fourth industrial revolution. Gartner, a consulting firm, estimates that China's IT technology expenditure in 2018 was 2.6 trillion yuan (337 billion euros). The share of software and data center systems is 250 billion yuan (32 billion euros). Government support also encourages companies to invest more in this area, such as the Internet of things. Market observers estimate that by 2025, one third of the world's industrial IOT connections (iiot) will be in China.

China's digital industry platform has faced global competition. One of the most important platforms is the aerospace cloud network established by China Aerospace Science and industry. High tech companies in these countries are directly controlled by the government. The industrial application digital platform developed by home appliance manufacturer Haier and Internet giant Alibaba is also being used more and more.

China is investing a lot of money to lead the fourth industrial revolution, so China's promotion of the digital platform economy needs to be seen in the context of various policies and measures to promote innovation. These include "Internet" and "made in China 2025". The latest initiatives such as "China standard 2035" are a strategy to set standards for innovative technologies such as artificial intelligence (AI), cloud computing, Internet of things and big data.

The commercial interests of China's Internet giants and the government's initiative to merge traditional industries with advanced information and communication technology (ICT) have promoted the development of industrial application digital platforms. But in fact, in many areas, China's industrial production is not very developed.

This is one of the main reasons for the continuous development of digital service platform on the one hand, and industrial digitization is still in its infancy on the other hand. Successful cases from China include tiktok video platform, Taobao e-commerce portal and Tencent's wechat platform, which has many functions. On the other hand, for example, relatively few Chinese companies are still using cloud solutions. According to China's survey in 2018, this proportion is only 30.8% (US: 50%, Germany: 73%).

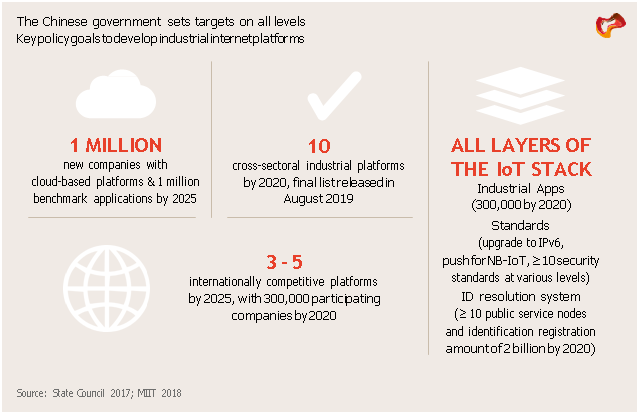

China hopes to catch up here. "Millions of companies go to the cloud" is the key premise for using digital platforms. It also sets the goal of creating the world's leading digital industrial platform, ten double cross platforms and 300000 industrial apps by 2020.

Figure 2 China targets in the report

Top down industrial Internet development

The Ministry of industry and information technology of China is responsible for the development of digital industry platform. In 2018, the Ministry of industry and information technology released the list of 93 industrial Internet projects for the first time for the construction, expansion, supervision and standardization of Chinese platforms. The first project is funded by the Ministry of Finance (MOF) of China with an amount of 4.9 billion yuan (679 million euros).

The Ministry of industry and information technology has also promoted the development of the industrial Internet Industry Alliance (AII), which is the main forum for interaction between decision makers and the industry. Aii was founded in 2016 and has more than 1300 members. This also includes foreign companies such as SAP, Siemens, Schneider Electric and Ge. The alliance determines the technical standards of China's industrial Internet platform.

The task of state-owned enterprises is to establish a platform for specific industries. For example, the subsidiary of oil giant Sinopec has established a platform for the petrochemical industry.

Three factors are promoting the establishment of China's digital industry platform: the government's strategic measures to ensure that state-owned enterprises develop platforms in key industries. Then, private companies also began to become active. Large Internet and telecom groups are increasingly opening up the B2B field because the number of users on their B2C platform has stagnated.

In June 2019, "central enterprise industrial Internet financing platform" was launched. It includes 289 state-owned companies, including large companies, such as China National Shipbuilding Corporation, steel manufacturer Baosteel (which has been working with Siemens since 2015) and Sinopec Yingke (belonging to Sinopec Group). Many companies have established cloud platforms, which are designed to stimulate collaborative R & D and create synergies.

The use of consumer behavior data is crucial for optimizing industrial production and developing industry 4.0. Chinese ICT companies such as Alibaba, Tencent, Huawei and Baidu can access data from a large number of Internet users.

Some ICT participants in China will benefit from their advantages in developing innovative applications. Take Baidu as an example, the world's first autopilot car open source technology platform has 130 partners, including large German automakers.

China lacks the core competence of platform development

China's weakness is also obvious. Structurally, it still relies on core components produced abroad, such as industrial software. This creates opportunities for foreign companies.

China lacks domestic solutions in key areas of industrial Internet platform architecture. This includes:

• sensors: the people's Republic of China must import nearly 80% of advanced sensors and up to 90% of chips to meet domestic demand.

• Equipment Connection: in 2019, 95% of high-quality programmable logic controller (PLC) and general communication protocol (CIP) were imported. Incompatibility between the products of different foreign companies is also a problem.

• software as a service (SaaS): more than 90% of the industrial software used in high-end fields in China comes from abroad. Sap, Microsoft and salesforce dominate the Chinese market.

The Chinese government is aware of these shortcomings and has plans to overcome them. This includes the following key points:

• one belt, one road, one is the development of SupET, the other is the development of a pilot project for specific areas (such as the Zhejiang Alibaba's SupET, Guizhou's CASICloud or Xugong Group's XREA).

• try more market driven financing mechanisms, including private capital investment, to reduce the dominant government subsidies.

• develop integrated systems to standardize the industrial Internet by 2020

So far, it is difficult for Chinese companies to work in iiot due to the lack of specifications in terms of compatibility, data ownership and data security. Therefore, China's regulators hope to see more effective technical standards by 2020 and establish a basic standardization system for the industrial Internet.

There are 324 Chinese industrial Internet standards, which are awaiting formal formulation. China Industrial Internet industry alliance aii also classified China's platform standardization as an early stage. This means that standardization is an area in which foreign enterprises can and should continue to cooperate with China.

Millions of enterprises on the cloud

According to the data of International Data Corporation (IDC), an American market research company, China accounted for 28% of the global Internet of things (IOT) expenditure and 29% of the total investment in robotics in 2017. By 2025, China will account for one third (4.1 billion of global industrial Internet of things connections (iiot)).

But for foreign enterprises, it can be said to be a conditional partnership. The degree of foreign participation depends on China's technology needs.

Chinese representatives often formally emphasize the cross-border, mutually beneficial and win-win characteristics of the digital platform economy, but there is no official mention of efforts to strive for self-sufficiency.

Many of the digital platforms analyzed in this study were created on the basis of establishing strategic partnerships with foreign companies (such as Siemens, Bosch, SAP or GE) and benefited from foreign research. However, China hopes to develop domestic production capacity in the long term and put its company in an advantageous position compared with foreign competitors.

Our observations show that foreign participants can only affect the regulatory development in the field of digital industrial platforms to a limited extent. The regulatory environment is conducive to domestic solutions in the digital platform economy. For foreign companies wishing to succeed in China's digital platform economy, network security and data regulations are the biggest challenges.

Opportunities for Germany

For China, Germany is an important partner in its own industrial 4.0 development. German companies and institutions also play a central role in establishing a digital industry platform in China, and the two countries cooperate closely in R & D in this field. For example:

• the R & D organization behind Haier CAOS maintains close contact with many scientific research institutions in Germany.

• Siemens has supported the aerospace cloud network Indics cloud platform from the beginning.

As can be seen from the example of Indics, Germany plays a vital role in the development and internationalization of many Chinese digital industry platforms. CASIC works closely with German companies such as Siemens (completed the "strategic partnership in 2016") and sap (for software procurement). Indics aims at small and medium-sized enterprises (SMEs) in traditional industries by acting as a contact exchange point and realizing resource sharing through cloud based manufacturing. According to the company, 1.6 million users registered in 2018, with a transaction volume of more than 400 billion yuan.

In June 2019, skycloud launched an international version called casicloud indexes. At present, as part of the German Chinese research project, its services and functions are being studied to understand the process and possible use of new technologies, such as improving cloud technology and providing practical support to the company. It is part of the campus project funded by the Federal Ministry of education and Research (BMBF) and the Ministry of science and technology of China (most). The purpose is to reduce the complexity of digital value creation.

These projects are part of the broader efforts of China and Germany to promote cooperation between science and companies and familiarize themselves with the industrial policies and methods adopted by each other's countries. Both sides are very interested.

The cooperation is based on the memorandum of understanding signed by the German Federal Ministry of economy (BMWi) and the Chinese Ministry of industry and information technology (MIIT) in July 2015, which aims to promote "China Germany cooperation in the field of industry 4.0". Joint statement of intent between BMBF and most on the theme of "intelligent manufacturing (industry 4.0) and intelligent services" on January 19, 2016.

The possibility of German platform providers providing services to Chinese customers is still limited. However, opportunities may open in the areas of sensor use / integration, device connectivity or "software as a service" solutions.

It is certain that China's rapid development in the field of digital industrial platform needs the attention of German participants at all levels of politics and commerce. Germany must not hesitate to reduce potential risks.

Advice to German participants

1. Look at China's advantages more differently. We need to have a solid understanding of China's innovation ability, not just the lighthouse project. In order to effectively evaluate China's platform economy, it is necessary to conduct more research on regional characteristics and development stages.

2. Conditional cooperation with China. China still relies heavily on foreign iiot components and services. German participants can use it to demand greater transparency in the application of cybersecurity regulations and equal market access for foreign companies. At the same time, in-depth cooperation with China in the field of industry 4.0 is in Germany's interests.

3. Mitigate the risks brought by China's special political environment. China's efforts to strive for independence in the industrial Internet have brought challenges to German partners. Joint research must be conditional; The protection of intellectual property rights must be a priority in cooperation negotiations.

The Chinese market has attracted the attention of German enterprises because of its size: in 2018, China invested 2.6 trillion yuan (337 billion euros) in IT technology, of which 250 billion yuan (32 billion euros) was used for software and data center systems. The financial measures provided by the Chinese government for companies to use cloud and Internet of things software will help them make more investment in these fields, So as to produce a large number of industrial data.

Due to the strength of German manufacturing, Germany can provide many services to China, including high-level manufacturing digitization and leading industrial Internet products and services.

China is making use of the traditional advantages of the German economy - a solid industrial foundation - to promote its own development of a globally competitive digital industrial platform. Therefore, for German participants, a deeper and systematic understanding of China's digital platform economy is essential. Only in this way can Germany better protect its own interests and communicate with China.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853