-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2599

TeslaRide the dust,With one's own efforts, the pure electric vehicle has opened up the situation.From January to June 2020, the cumulative sales volume of new energy passenger vehicles in the world was 947000. Tesla salesnear180 thousandVehicleRanked first, with a market share of 19%, which is the sum of Volkswagen, BMW and BYD ranked second to fourth.

However, what people are not familiar with is that this enterprise has also achieved the ultimate in manufacturing technology.

From 70 to 1!

The world's largest automobile die casting machine has been installed, which can make the rear of the automobile body, including the anti-collision beam, integrated.

This is a scene of Tesla pure electric vehicle factory in the United States in August. Its SUV model: model y will adopt a new manufacturing process.

Previously, different die casting machines were used for different frame components. It is first cast into individual parts and then reassembled together to form a complete frame. The whole assembly process is time-consuming, laborious and costly.

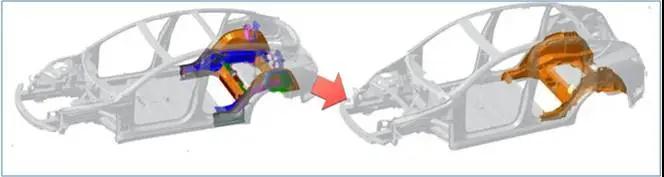

Tesla's die casting machine uses the latest aluminum casting process, which will reduce the casting parts of Tesla Model y from 70 to 1, and greatly improve the structural stability of the body. This means that now one machine can complete most of the casting work of the frame. The first mock exam of small and large parts is much better than one mold, and the intermediate cost of finishing and assembly is reduced. The cost will be reduced by more than 70%. This means that the work of 50 die casting machines and 200 machining centers is now completed by a large die casting machine.

Figure 1 # reduction of casting parts from 70 to 1

Die casting machineHigh speed and high voltageThe function of is aA grand project,Just byDie casting machine manufacturerIt's impossibleWhat can be done must be doneFollowuseHouseholds, research institutes, etc, the product design is integrated with the design of die-casting machine and die-casting die.

In fact, Tesla has been simplifying the design of automotive platforms and achieving a higher degree of automation in the manufacturing process. Last summer, the company issued the patent of "multi-directional integrated casting machine for frame", and disclosed the new casting machine Tesla plans to use for y-car.

In order to lighten the weight and try to integrate multiple parts into one product design, there has been some progress in China, such as the combined design of motorcycle parts by Huicheng in China. But Tesla's die casting machine is a behemoth.

This means that Tesla is not only making cars, but also making machines. This is a concept of deep manufacturing.

Violation of streamline pickup

Remember last year's Tesla electric pickup conference, the CyberTruck that make complaints about people? Sharp edges and corners and obvious broken lines. Why did Tesla abandon the streamlined design language that has lasted for many years and build a pickup truck with sharp and straight lines?

Figure 2. Tesla's electric pickup

Due to the demanding and rough application scenarios of pickups and the demands of body strength, Tesla chose to use a high-strength super hard cold-rolled stainless steel alloy. Cybertruck is bulletproof even for 9mm pistols. This stainless steel alloy material cannot be stamped because it will damage the stamping machine. As the conventional body manufacturing methods are no longer applicable, Tesla has to explore new manufacturing methods. It nicks and bends the stainless steel plate, which is bent into the plane shape of the pickup like origami, and then welded to form. This new body manufacturing method will also provide Tesla with the flexibility to adjust, reduce costs and shorten manufacturing time through a unique simple flat panel design.

In this way, musk set himself the problem of material and manufacturing cycle. Once solved, it will produce a jumping height.

It is worth noting that the "star boat" heavy launch vehicle developed by Tesla's SpaceX company also makes the same materials. A material that can be compatible with rockets and cars. Looking for ways of large-scale reuse is Tesla's consistent method. The person in charge of this material works in both Tesla Motors and SpaceX Aerospace departments. This person in charge, who is an important person in the integrated computing materials engineering ICEM in the United States, develops alloys through the calculation of material properties, that is, "design materials", so as to greatly reduce the cost of material development.

Musk has a set of "engineering cross methodology". As early as 2017, he explained that he specially opened up the core technical departments of Tesla and SpaceX, so as to cross apply the expertise in the fields of rockets, spacecraft and automobile industry. With the help of SpaceX scientists, Tesla engineers reduced the manufacturing hours of model 3 by 8 hours.

From heaven to earth, design and manufacturing can find similarities.

Original slimming technique

What is the heaviest part of a car except the engine and chassis?

Ordinary people may not think: that is the electrical harness. Weight is a big obstacle to fuel consumption and battery life. The harness not only brings weight problems, but also restricts the efficiency of automobile production. As one of the four processes, vehicle assembly has the lowest automation rate compared with the other three processes. During the final assembly of the car, the complex shuttle wiring harness in the car body needs to be completed manually.

Musk's view on manufacturing is that only "machine manufacturing machine" can greatly reduce the cost. Using cheaper and scalable programs allows SpaceX to complete launch missions at a low cost and efficiently, which is unmatched by NASA's traditional manufacturing methods.

Since we want to use "machines to make machines", we must first transform the wire rod process, so that the robot can "thread needles" in the final assembly process, greatly reducing the labor cost.

Moreover, reducing the harness length as much as possible has become a new goal. Tesla has made great progress. The model s vehicle harness is 3km long, but it will be reduced by half in model 3, only 1500m. Such significant progress is due to the innovation of the new automotive electronic and electrical E / E architecture. In the past, the distributed electronic control unit (which brings complex wiring) has been replaced by the central centralized control. In the past, a car had 70-80 electronic control units ECU, but now only a few electronic control units are required. This benefits from the powerful chip computing and storage capabilities. The control of similar driving assistance and entertainment systems are incorporated into the central computing module. At the same time, the power distribution architecture also fully considers the requirements of power redundancy. These greatly reduce wiring.

On model y, the harness length is intended to be directly reduced to 100m, which is only 3% of model s. It's amazing progress. At present, it remains to be seen whether it is really realized. This has something to do with aviation technology. The flexible printed circuit FPC technology used in Mars rover curiosity is also used on the harness of model y. This technology borrowed from space to the ground will produce amazing technical results.

The slimming of the harness will make the vehicle lightweight effect obvious. Because the vehicle weight is closely related to the endurance. Although the model y car body is larger and consumes more materials, it will be consistent with model 3 in terms of production cost. These are Tesla's manufacturing principles of "economy first".

Extreme manufacturing

Behind this is Tesla's two "extreme manufacturing" concepts.

On the one hand, it pursues "extreme manufacturing", marches into the largest and most complex manufacturing process, and pursues mass effect. Extreme manufacturing is also a common kind of equipment manufacturing industry, which is suitable for extreme cold, extreme heat and other harsh environments. However, they are generally manufactured in small batches or even single pieces. And mass extreme manufacturing is a kind of purgatory suffering. It is a great challenge to technology and materials, which needs a deeper underlying theoretical basis as support.

On the other hand, Tesla also pursues high-speed manufacturing. Above the noisy workshop full of automation, stamping machines and robots, there is a legendary "second floor of Tesla". There are research and development of batteries, electronic equipment and transmission systems. It is the gathering place of the most advanced manufacturing technology in the company. For example, robots that run faster than workshops often use carbon fiber instead of steel. That's where Tesla pursues rapid R & D. Fast iteration is realized through simulation technology and process running in of small laboratory. And it is rapidly developed from the second floor and transferred to the manufacturing site on the first floor. With this method, Tesla can improve the product up to 50 times a week. This self owned small-scale production workshop allows operators, engineers, designers and product teams to consolidate necessary knowledge through trial production. When the mass production scale exceeds the manufacturing capacity of the super second floor, it means that the process of the product has been polished, and outsourcing to OEM manufacturers will be successful. Those agents take over not only orders, but proven manufacturing processes.

These are unique places made by Tesla. It can be said that the boundary of manufacturing has been pushed to the extreme.

What's the real bet?

Traditional car factories have long entered the Red Sea competition. The chassis has been changed once in three years, once in five years, and the body has even been changed once in five years. Although traditional car manufacturers frequently change models and rigidly pursue customer-defined value, users have long been aesthetic fatigue and are easy to pick fancy eyes.

Tesla's idea is completely different. It gambles a huge amount of production capacity for each single model. This kind of thinking is actually the same as apple.

Apple mobile phone also relied on a single model to crush multiple models of other brands. The Apple App Store ecosystem meets diversified needs. In contrast, the shape of the mobile phone has become the least important thing. Since July 2010, the total downloads of IOS app store have exceeded 170 billion times, with a revenue of more than 130 billion US dollars. andIn 2020, apple continued to rise against the trend. At the most depressed moment of the global economy, its market value reached $2.2 trillion at the end of August. Behind this, itsService revenue has become the main business, with Q2 reaching US $13.3 billion, a year-on-year increase of 17%, reaching a new record.

Similarly, Tesla can continue to improve vehicle performance without additional vehicle investment by relying on software defined functions and remote software upgrade. This means that a single model can also sweep the market.

Due to the production capacity, it actually determines whether the large-scale die-casting equipment is worth investing. It is very difficult for traditional car factories to introduce large-scale equipment. Even if large-scale special aircraft equipment is used to increase the production capacity to 1 million vehicles a year and reduce the cost by 20%, it can be earned back. The best-selling Toyota Camry sells about 300000 in North America a year. The sales volume of 1 million can't be expected at all.

Tesla basically set this as a base.

Modely is Tesla's real profit harvester in the future. First, SUV has huge market demand, and the global SUV market has experienced explosive growth. In 2018, the sales of SUV models reached 30 million, which means that one SUV can be sold on the market almost every second. From the perspective of manufacturers, the annual sales of SUV models of Toyota, Nissan, Honda, jeep, Hyundai, Ford, Volkswagen and Kia all exceed 1 million. Obviously, as long as model y can get a small piece of cake from the SUV market, Tesla can make a lot of money.

This is not difficult for Tesla.

In the North American market, model 3 won the sales champion of the same level in a short time. In the U.S. Small and medium-sized luxury car segment, its market share is even as high as 24%, and has been in short supply.

Tesla plans to assemble up to 1 million vehicles from the model y architecture platform of this SUV every year. And it is estimated that the car body will be greatly changed in five years (or even five years). This means that the total production is 5 million vehicles. Only under this premise can Tesla invest in equipment at all costs.

In this way, it seems that the fundamental self-confidence to invest in "extreme manufacturing" on a large scale comes from sales, not entirely the technology itself.

Notes: economic primacy behind subversion

Tesla continues to optimize the machine to continuously reduce the complexity of vehicle manufacturing and improve manufacturing efficiency while saving costs. In the process of climbing out of the hell of model 3 production, Tesla should pay special attention to the accumulation of manufacturing experience. This is a huge pit left by the century old automobile manufacturing industry for cutting-edge automobile manufacturing forces. Now that it has climbed out of these pits, Tesla plans to use these experiences in the mass production of model y. 75% of the components of model y are from model 3. This is Tesla's "economy first" principle: reuse, reuse is the best choice.

Musk, who has made countless detours in mass production, believes that "the best parts are no parts, and the best process is no process". This kind of nonsense will inspire a group of talented engineers to think. It needs a subversive design concept to compete with each other in various fields such as materials, process methods and digitization from the principle of economy, so as to create a subversive manufacturing road.

Behind the beautiful and amazing products, they are actually made of magic.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853