-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2126

With the application of various ICT technologies in the traditional industrial field, one of the myths we can witness is that the digital world is trying to establish a dominant position parallel to the physical world. The unstoppable enterprise digital transformation shows more complex diversity and scale under the tide of AI, IOT, 5g and cloud computing. And this is the best soil for creativity.

A new paradise belonging to innovators is rising. So, where does the enterprise's sustainable innovation ability come from? The practice of some pioneers may be used for reference.

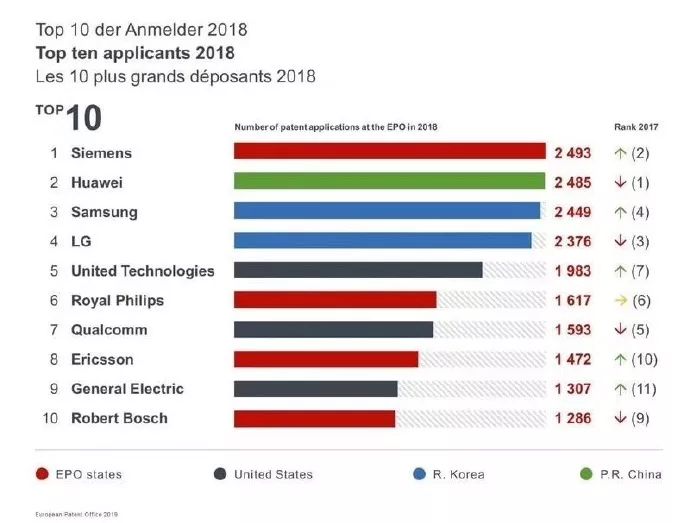

In March 2019, the European Patent Office launched the top 10 patent ranking list, and Siemens ranked first in the patent application ranking released by the European Patent Office. Its annual total number of inventions worldwide is 7300, equivalent to an average of 33 inventions per working day. This number has pressed the giants of ICT industry and become a model of industrial innovation.

Among them, more than 25% of patent applications are concentrated in the digital field; In the field of machine learning process alone, there are more than 50 patents. How can the manufacturing industry be no worse in front of the ICT industry? The belief in digitization is leading this technology giant to a new future. This is a dual belief. It should not only change itself, but also promote industrial users who believe in digital transformation.

Behind this, we need a complete set of innovative mechanisms, like a powerful heart, driving the beat of the digital pulse.

How far is the application of science and technology

The central enterprise research institute is the most graceful gift in the history of industrial development in the 20th century. It directly promotes the development of the whole industry. The central enterprise research institute sprouted in Britain and France, started in Germany, then developed in the United States and spread to Japan. How far is the distance between the application of science and technology? In Newton's time, it was the order of the ends of the earth, and the two were so far away that they could hardly be compatible. In Germany, which pioneered the wind of basic research and application, chemical industry giants initiated from printing and dyeing, whether Bayer or BASF, have greatly promoted the commercial application of science. The Siemens Central Research Institute, founded in 1914, has brought the two to a hand-in-hand distance. The founder put his efforts into practice and perfectly combined the exploration of science with the application of technology. Over the next hundred years, Academia Sinica made great contributions to promote siemens to become an international industrial giant.

In fact, the research focus of Siemens Central Research Institute after World War II has experienced four main stages: the 1950s and 1960s are characterized by the so-called technological advancement. At this stage, researchers enjoy great freedom and are rarely subject to budget constraints. By the 1970s, the impact of the market began to deepen, so R & D activities were closer to practical applications, and the research work of Academia Sinica was closer to the research work of R & D departments under various groups. Since the 1980s, with the advancement of globalization, its focus is to quickly transform research results into market accepted products.

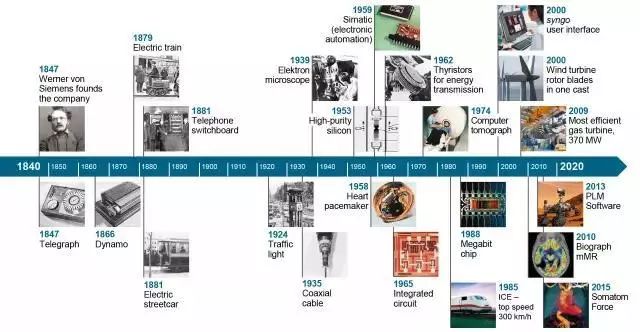

Among the many innovations of Siemens, several inventions have truly become milestones in the history of contemporary technology, including computed tomography (1974), 4-megabit DRAM chip (1988), single cast wind turbine blade (2000), a record gas turbine (2009) and PLM industrial software (up to 2013).

Today, the world's largest particle accelerator, the European Large Hadron Collider, can produce more than 100 terabytes of data per day - which is also the largest capacity that neuroscientists estimate that the human brain can have. The data analysis software of Siemens Central Research Institute analyzes its data and integrates heterogeneous data such as sensors, detectors, safety systems and control rooms from various locations. It used to take scientists two weeks to find out the source of the fault alarm, but now it takes only half an hour.

In Siemens, around the market demand, each business department has established its own core technology department, while the Central Research Institute of cross business platform undertakes a higher level of scientific research activities, mainly responsible for developing cutting-edge technologies of strategic significance for the future business of the enterprise. From the whole product life cycle, it is in the earliest incubation stage and at the top of the food chain. However, it needs the most terminal nerve endings to sense user needs, so as to form the "matrix" of cutting-edge technology. When some business departments think that a terminal signal needs to be rapidly amplified, the technology "matrix" begins to be activated and enter a higher level of research, and the Central Research Institute will continue to provide technical support.

This step-by-step amplification effect actually depends on an intuitive judgment. Success requires great tolerance for innovation and failure. In the 1960s and 1970s, Japan successfully commercialized carbon fiber by relying on the key role played by the Basic Research Institute of Osaka Institute of industry. Dr. Kondo, the greatest hero, received similar funding from the open and inclusive innovation atmosphere of Osaka Institute of industry. At that time, the United States was repeatedly defeated in the commercial exploration of carbon fiber. Inspired by the latest developments in the United States at that time, Dr. Kondo was given sufficient funds to try his ideas. Kondo successfully promoted this project to the ranks of major projects in only three months, and successfully applied for a patent in 1959. This is a milestone for Japan to almost monopolize the carbon fiber market for 50 years.

Judging from the development of the United States, the basic research institutes of many enterprises are shrinking. Bell halo is no longer, Xerox park center has become a small research businessman. For them, the basic research institute is a gradually drying moat. In this way, the central basic experimental Institute launched by Huawei this year is simply going against the "trend". Only when the moat has sufficient water, can an enterprise get rid of its competitors and stand in an invincible position of innovation.

Eyes of the future look back

All companies with long-standing foundation need to have an overall strategic judgment. If it is to become a trendsetter of industrial technology, it must have a "future eye" and try to see through the upcoming opportunities.

This is a strategic drive based on the future. As early as 2014, Siemens proposed the Vision 2020 strategy, which first defined the layered strategy of e-a-d (electrical, automation and digitization), and divided a clear boundary for the traditional electrification and automation industries. This boundary is not used to distinguish the high-end and low-end of product technology, but strengthens a kind of digital thinking.

Industrial software is an important support. In the past decade, Siemens has quietly ranked among the top ten software companies in the world. However, such a result does not seem to be surprising. As early as 2004, when Siemens' R & D cost was 5.1 billion euros, more than 50% of the cost was related to software. Obviously, Siemens did not become a software giant today. It is only today that we realize that industrial software is the most important muscle and bone for the development of industry to high-level and enterprises to digital enterprises. In this sense, the acquisition of American PLM Software UGS in 2006 was generally regarded by the industry as a masterstroke, but it was not an impulse on a whim. It is a strategic move to continuously pursue innovation and an inevitable result driven by strategy. It then completed mergers and acquisitions and invested more than US $10 billion, including electronic design automation software mentor graphics, automobile simulation software TASS and app low code software mendix, all of which continued to echo a voice.

In the company's vision 2020 strategy announced in 2018, Siemens made major adjustments to the organization. The core is to give businesses more freedom to operate independently to accelerate business growth, and digitization runs through major business groups. This is a firm and continuous belief in digital transformation.

A great strategy needs to run farther ahead of the times. Looking back at the strategic locomotive coming from Mercedes Benz, what angle will it be?

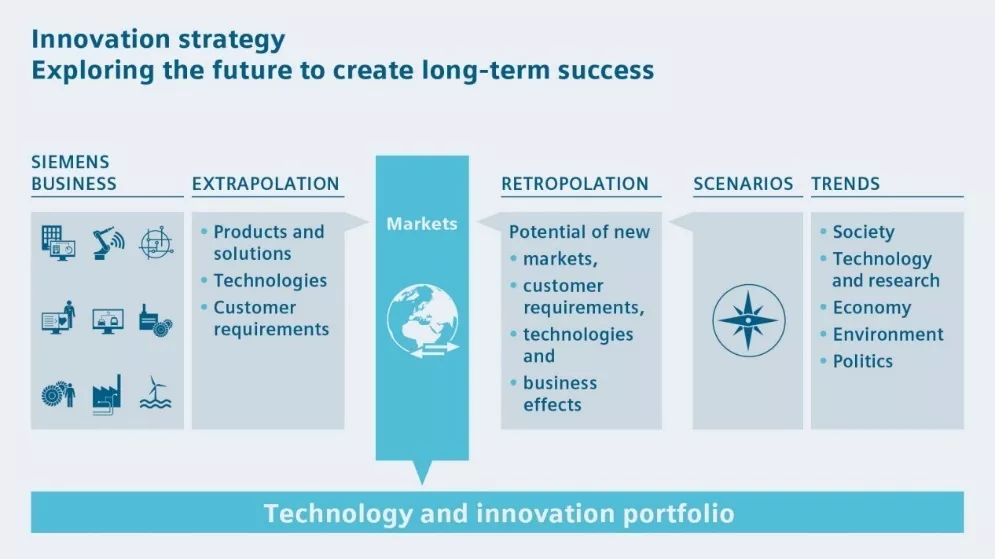

This kind of looking back is not always the mystery of watching celestial phenomena at night and skillful calculation. Behind the strategic choice, there is a set of ideas worthy of reference. Siemens combines two powerful tools to predict future customer needs. One is extrapolation, that is to predict the current technology and product series to the future; One is inversion, that is to create a "picture of the future" and use it to draw the tasks and problems that need to be handled today to realize this vision. Many of Siemens Central Research Institute are "scientists from the future". Their job is to communicate with experts everywhere, read literature, and find innovative technologies in the future, so as to generate a "vision of the future".

In fact, all mature enterprises will be wary of disruptive technologies. However, the only way to prevent subversion is to gain insight into disruptive technologies and the signs of the blue ocean market. Induction and inversion enable an enterprise to perceive the signs of "disruptive" technology as early as possible, and adopt innovation strategy to prepare for change.

After "hydrogenation" was written into the government work report this year, hydrogen fuel cells immediately experienced a heat wave in China. In fact, as early as 1998, Academia Sinica began to suggest strengthening the research of hydrogen fuel cells. This was an observation twenty years ago! Ten years ago, Siemens began to strengthen the research and application of hydrogen energy. The hydrogen energy related solutions provided by the business departments of oil, gas and power groups are the multi-dimensional energy conversion and utilization system with hydrogen energy as the core, covering the core business of the whole hydrogen energy industry chain.

All thinking about the future of China's industry needs such a "future eye". This will become a force drawn from the perspective of the future, which brings the foresight of innovation strategy.

Ecological power

Strategy needs to answer the choice of technology, and ecology means environment and necessary nutrients, which provides soil for the rapid implementation of technology.

People are looking forward to AI such technology can quickly enter the industry. The integration of physical assets and the digital world has become a standard thinking sweeping everything at present. However, there are a lot of fuzzy areas in the middle, and artificial intelligence is trying to make these fuzzy areas clear. For example, in Qingdao refinery, anomaly detection of core equipment is a headache. In the era of extensive energy conservation in previous years, only advanced equipment needs to be replaced, such as a new frequency converter; With the higher requirements of energy conservation and emission reduction and cost actuarial, enterprises are finding the refined energy conservation based on data from the perspective of tapping the potential of equipment and through the means of artificial intelligence. In China Resources Power, the centralized monitoring and analysis expert system based on hybrid cloud technology will apply digital power plant and artificial intelligence technology, integrate its own years of experience, and help the power plant reduce coal consumption and improve equipment reliability through continuous learning of historical data and real-time data. Only changing the brain without changing the equipment, the operation efficiency of the factory becomes clear and efficient.

However, as a digital enabling technology, AI can no longer be simply regarded as a single element. More precisely, it seems to be playing a connecting role at the moment. This is the thinking of Siemens establishing AI Lab in Munich, Germany in 2017. It provides a space for cooperation to evaluate the feasibility of new ideas and aims to accelerate the implementation of innovative ideas. If you can sit at the same table with customers, you can quickly make solutions and prototype systems to achieve preliminary technical verification. This is a power of face-to-face communication, and the artificial intelligence laboratory has increased its strength.

IDEO, the world's most famous design company, is famous for its extraordinary imagination. Its most magical and common weapon is brainstorming. IDEO a team will generate 100 ideas in one hour during brainstorming. 100 kinds! An hour. IDEO generates hundreds of ideas in brainstorming, and then quickly negates and discriminates a small part through whiteboard, prototype and digital analysis software. Artificial intelligence is greatly accelerating this selection process.

AI Lab is currently forming a new technology fashion, flexibly working closely with global communities and groups to jointly discover new opportunities. Innovation is about socializing. Here, Siemens AI Lab is working closely with various business departments and attracting external creatives. So far, 20 projects have been hatched.

Just last week, after running in Germany for more than a year, AI Lab officially announced its landing in China. This is a belief in open innovation: innovation energy stimulated by interaction. If you look back on the great industrial laboratories in the world, you will find that Bell Labs, one of the largest innovation incubators in history, advocates the interaction between members. The most classic move is that Bell Labs has set up a long corridor, and the bathroom and canteen are at the end. Any researcher passes by his colleagues' laboratory several times a day. The highly stylized corridor will help us understand some of the logic behind the AI lab.

As the basis of deep learning, artificial intelligence needs a lot of corpus and context, and it needs to well understand one application scenario after another. The installed capacity of existing physical assets is the most fertile land. If the data is crude oil, then AI is the most important heavy mining machine. With the help of ubiquitous IOT connection and 5g technology with high bandwidth, high rate and low delay, Siemens expects mindsphere, an open Internet of things operating system based on cloud, to become an effective oil refinery.

In an interconnected City, to manage the complex and mobile traffic ecosystem composed of roads, vehicles, people and weather, we need to take a more comprehensive approach to manage mobility. Connected vehicles send data in real time, the status of infrastructure systems, and road users connected to smart phones will be very active and generate huge data in the invisible data zone. This rich and growing data source is profoundly changing the types of transportation services in the future. In Berlin, Germany, a "Siemens City 2.0" with a new concept and an investment of 600 million euros includes the interaction mechanism of ecosystem from the beginning of construction, closely linking work, life, school and university education and the innovation ability of start-ups. Starting from the original ecology, the construction of xiong'an may also be used for reference.

Mindshpere is building such an ecological rainforest. In addition to strengthening the connection with an installed capacity of up to 1.3 million, it is also forming a stable ecological partnership with major enterprises. The number of its alliance members has expanded from 18 in early 2018 to 90 now. In April, it announced the establishment of a new partnership with SAS, a well-known statistical analysis software in the industry, to conduct large-scale data analysis on the mindshpere platform. The database originally developed using SAS model will be automatically integrated into mindshpere. This means that the data crude oil stored in ubiquitous machines, facilities and vehicles will be easily exploited.

At the end of March, the German automobile industry ushered in a major event of industrial Internet. The Volkswagen Industrial cloud jointly developed by Volkswagen AG and Amazon cloud computing service platform AWS was officially launched. As an integration partner, Siemens provides digital services of industrial cloud for various mechanical equipment in 122 factories around the world. This means that Volkswagen's global supply chain, more than 1500 suppliers and more than 30000 branches will also be brought into the ecosystem of data transparency. The German government is considering reserving 100m frequency band for several major automobile groups in advance in the 5g era. If implemented, Volkswagen Industrial cloud will be a complete and independent cloud manufacturing Empire integrating communication, digitization and production. It is unprecedented in history to break away from the control of telecom operators over communication. 5g has brought the manufacturing industry into an unimaginable new partner era. Digital technology has no boundary mobility, so that ecological species will spread faster and more dramatic.

Notes

What will happen to the future world? Interconnected cities, intelligent manufacturing, thinking power, ubiquitous energy, digital buildings and so on are all full of desire. The digital twin is building a new digital space above all the physical world that can be seen by eyes. Among them, the full stack technology is advancing at full speed. The mutual integration of 5g, edge computing, digital technology, additive manufacturing and advanced robots makes innovation have a huge space to play. The innovation mechanism in the digital age is driving the evolution of outstanding enterprises and the advancement of the times with a rich ecological law.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853