-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2296

"Spare tire crisis" is like a lightning bolt, which cuts through the dark sky. Those hidden neck clamping techniques show ferocious teeth in a short light. The awareness of spare wheel crisis has unprecedentedly popularized people's understanding of "industrial concealed weapon": it quietly lurks in the industrial field, its volume is very small, but it has created huge wealth for industry. You can't live without it. You can't see it. It is the most humble and neutral powerful tool. However, in extreme times, it may become a deadly political weapon.

CAD tool software of computer aided design, together with many of its brothers, such as simulation software CAE and electronic design automation software EDA, is such an "industrial concealed weapon".

A righteous man flying over the eaves and walls

It is hard to imagine that CAD, a computer-aided design software that has been developed in China for nearly half a century, will re-enter the eyes with such a declaration of "defense between enterprise and country" like other short board technologies. For more than 40 years, the independent CAD industry has almost lost its recognition from following the international market to booming, to falling on the spot, and has become an industry that has not attracted much attention in the industrial gap.

However, for an independent economy, CAD industry has great strategic significance, which is related to the design ability of the whole country and the source of technological innovation. In 1989, the American Academy of Engineering Sciences rated seven of the world's most outstanding engineering and technological achievements in recent 25 years, of which the fourth is CAD / CAM. In March 1991, the U.S. government published the cross century national key technology development strategy, listing 22 key projects in six major technical fields, and CAD / CAM technology is closely related to 11 of the two major fields.

However, after decades of development in China, in the field of high-end 3D CAD, almost all domestic software has been destroyed, and there are still some surviving fighters in the middle and low end; Similarly, the electronic design automation software EDA in the field of chip design is almost all owned by three American companies (one was acquired by Siemens).

Entrepreneurs walking in this industry are basically chivalrous men who fly from eaves to walls. There is no way to go.2018Dassault, an industrial software provider, earned $5.8 billion, while Autodesk reached a record $2.6 billion. China's CAD software manufacturers are basically hovering between 20 million and 200 million yuan. They are more like righteous men in the Jianghu, walking on the cliffs of the niche market.

Brave and enterprising in the past

Back in those years, China's scientists and engineers also kept up with the development of developed countries.

In 1963, with the "man-machine dialogue system" of Dr. Sutherland of MIT, a new chapter of graphical interface was created. It can complete the work that usually takes several weeks in 10-15 minutes, which shocked the whole engineering community. The far-reaching computer-aided design CAD was born. In the subsequent development, many technologies came out of universities. This is the University's best gift to the engineering community.

Almost synchronously, Chinese scientists and engineering circles responded quickly and began to study the application of CAD / CAM technology in aviation and shipbuilding engineering in the mid-1960s. Since the mid-1970s, many colleges and research institutes have done a lot of work in CAD / CAM research, which has promoted the rapid development of CAX technology.

In 1975, Xi'an Jiaotong University developed model 751 light pen graphic display. Within three years, 751 was finally equipped with basic software. On the basis of 751 system, Northwest University of technology and Shanghai Jiaotong University have carried out the earliest attempts in China, including applications in aircraft frame rib assembly fixture design, surface shape design and machining, modular machine tool design and so on.

It was a beautiful time when flowers were blooming all over the garden. In 1980, the national CAD research association of colleges and universities was established in Beijing Institute of technology. At this time, Shanghai Jiaotong University, Huazhong University of science and Technology (then known as Huazhong Institute of Technology), Dalian University of Technology (Dalian Institute of Technology) and many other units have done a lot of work in CAD research.

In 1984, Professor Tang Rongxi of Beihang (then Beijing Institute of Aeronautics) led a team to develop China's first polyhedral solid modeling prototype system panda. The most admirable thing is that Mr. Tang immediately disclosed the technology to domestic research institutes and schools and provided the source program at a low price or free of charge. Panda system flowed to the industry and became the enlightenment system of CAD at that time. Professor Tang's team closely followed the international situation, and then developed a geometric modeling and NC machining prototype system Panda4 based on wireframe and NURBS surface.

The great development of CAD in the United States and France has a deep relationship with aviation manufacturing. China's aviation manufacturing has also played a leading role in promoting the development of CAD. In 1986, the 7760 computer aided aircraft design, manufacturing and management system of the Ministry of aviation industry, namely 7760 CAD / CAMM system, was known as the first of the top ten scientific and technological achievements of that year. This project is also a battle of 100 people. More than 100 professors and experts from 27 different institutes and factories jointly tackle key problems. The software system has experienced the actual combat of Airbus 320 cargo door design, and has been applied in the development of "Feibao" aircraft. By the mid-1980s, some researchers had made statistics and found that more than 2000 sets of CAD systems had been developed by colleges and research institutions.

In that decade, the industry emerged infinite vitality. The HCS system of No. 11 Institute of No. 6 Shipbuilding Institute has officially passed the appraisal, which is the first shipbuilding integrated production system in China; The b-surf (3D-CAD) system suitable for the design and manufacturing of complex shape products, such as Zhou rurong of Nanjing Institute of Aeronautics, has stepped into the three-dimensional threshold. It can establish the whole machine digital simulation of two types of UAVs, and present various perspective and sectional views of the whole machine and its components on the graphics terminal of ibm4341 (which needed hundreds of thousands of yuan at that time).

In 1992, the super large scale integrated circuit computer aided design (IC-CAD) panda system passed the national appraisal in Beijing. Over four years, more than 200 developers from 16 units, including Beijing integrated circuit design center, worked together to overcome the difficulties. The system has 28 tools, covering all the functions of full custom IC forward design. It adopts domestic Huasheng workstation as hardware, UNIX system and standard C language programming, and the number of codes reaches 1.82 million. And right now,This kind of EDA softwareIt is a very big weakness in the field of chips. Cadence, which brazenly broke off the supply to ZTE last year, belongs to this kind of concealed weapon.

At that time, the development of CAD showed the edge of "engineer doctrine". At that time, simple managers had no speaking area. The development of the whole industry is directly promoted by scientists with engineer temperament. This is a history of the perfect combination of scientists and engineering. Its key research methods: combination, coordination and system are particularly impressive at present. It is these fledgling technical explorations that provide fuel for the "CAD application foundation" promoted by the whole country.

Government action

During this period, the government's actions can be described as fully positive, which seems to have greatly promoted the development of the industry.

In 1983, 8 ministries and commissions including the national science and Technology Commission held the first CAD Application Conference in Nantong, at which there was a voice for cultivating and developing independent copyright CAD industry; In the 863 plan, the implementable plan for further in-depth study of CAD is mentioned. During this period, the Ministry of machinery industry invested 82 million to organize the development of 4 sets of CAD general support software and CAD application systems for 24 key products.

At this time, the era of "drawing board" with high software enlightenment significance for Chinese industry has come. During the Eighth Five Year Plan period (1991-1995), eight ministries and commissions, including the State Science and Technology Commission, jointly reported to the State Council the report on vigorously cooperating in CAD application engineering. With the approval of the general office of the State Council, the "CAD application project" has been launched throughout the country. At that time, the director of the national science and Technology Commission put forward the call of "getting rid of the drawing board", which set off a wave of popularizing CAD technology and application all over the country. During the Eighth Five Year Plan period, nearly 800 million yuan was invested in CAD technology, and the output value of domestic CAD software was nearly 100 million yuan. It has generated indirect economic benefits of more than 10 billion yuan and trained 250000 CAD talents.

It should be said that although it is a small output value, the leverage effect has been magnified by 100 times, which fully shows the power of this industry.

"CAD application engineering" is listed as the top priority of the ninth five year plan. Machinery industry is the first pilot demonstration industry of CAD application engineering. In the autumn of 1995, the Ministry of machinery industry first launched the one-year "1215 project", selecting 112 enterprises with a certain technical foundation, such as beiren group, Beijing lifting machinery factory and Anhui forklift factory, as the first batch of "drawing board" pilot projects, and required to get rid of the drawing board in the leading product design in a short time. The project was launched in September 1995, with a total investment of 20 million and the introduction of 359 sets of various CAD software.

Then came the "1550 project". 1997 was defined as "CAD application development year" by the Ministry of machinery industry, with the implementation of "1550 project" as the core task. There are three main tasks of 1550 project: first, establish a CAD consulting service network system for mechanical industry; Second, complete the development and industrialization of five application software; Third, cultivate 50 CAD application demonstration enterprises, support 500 successful CAD application enterprises, and drive the CAD application of 5000 enterprises.

This kind of digital planning is really gratifying and full of step-by-step self-confidence. Similar references are still common in the planning of intelligent manufacturing and industrial Internet.

At the same time, CAD application engineering is also carried out in the transportation system and survey and construction system. The Ministry of construction has issued the outline of CAD technology development plan during the Ninth Five Year Plan period for the National Engineering Survey and design industry, which is mainly focused by Vice governors in many places.

During this period, the government has always attached great importance to the development of CAD industry. In 1998, ministries and commissions were merged and reorganized, even though the Ministry of machinery industry was abolished,Newly establishedThe Ministry of electronic information industry still ranks CAD software as the first of the eight key supported software industries.

This scenario is very similar to the current promotion of intelligent manufacturing, industrial Internet and artificial intelligence.

all flowers bloom together

In such an era when the government is so active, how can it lack the self-determination ambition that is eager to try?

"The goal that the share of domestic CAD system in the domestic market will reach about 40% in 2000" was soon put forward, "protecting the national intelligence intensive industry" has become a loud slogan.

In 1996, the domestic CAD software industry alliance first appeared in front of Chinese people with an overall image at the Shanghai CAD exhibition, and put forward "our banner of domestic software and our goal of national industry". The founding members include five companies, such as Cass of Chinese Academy of Sciences, Tsinghua Gaohua, Dakai, Wuhan Kaimu and Shenzhen Jonathan, and later expanded to more than a dozen, including jabic, Zhengzheng, Dongda alpai, Tongchuang, Datian, huaruan and Huaheng. In the second year, the alliance jointly launched the "97 domestic CAD golden autumn action" with the "national CAD application engineering coordination Steering Group Office" of the State Science and Technology Commission. The office provides some funds as subsidies, and the member companies of the alliance provide products. The implementation scope includes the first batch of 300 demonstration enterprises of national CAD application engineering and regional demonstration enterprises. 5% price subsidy shall be provided to suppliers, and priority of science and technology development loan application related to CAD application shall be provided to user enterprises, and discount interest shall be considered as appropriate.

However, the flower of CAD industry is open everywhere, but there is no concentration. According to incomplete statistics, in the last decade of the last century, there were more than 300 institutions engaged in CAD research and development in China. It can be divided into two camps. One is the two-dimensional CAD system of independent platform, and the other is the secondary development based on the most popular two-dimensional software AutoCAD at that time. However, looking closely at the past, one of the biggest features is that the birthplace of the whole CAD industry is basically from a university - which has cast a meaningful shadow on the sustainable development of the subsequent CAD industry.

Since the Seventh Five Year Plan in 1986, the technical level of China's CAD industry has risen step by step. According to the report of the science and Technology Commission in 1997, during the Eighth Five Year Plan period, the total installed capacity of gh-cad software of Gaohua company reached more than 5000 sets in one year; After evaluation, the PICAD supporting software platform of CASS software of Chinese Academy of Sciences can compete with foreign advanced two-dimensional CAD software, and cooperate with secondary development units. There are more than 8000 sets of software installed, driving a number of national CAD software.

According to the statistics of the former national CAD office, 600 enterprises participated in the "CAD application engineering technology development and application demonstration" project during the Ninth Five Year Plan period. The cumulative investment is 2.43 billion yuan, the annual sales of independent copyright CAD software is 650 million yuan, and there are 7 CAD software enterprises with an annual output value of more than 30 million yuan, with a total annual output value of nearly 400 million yuan.

At that time, another vigorous CIMS (Computer Integrated Manufacturing) project was accompanied by made in China. Under the theme of CIMS filled with joy and excitement, the whole CAD industry is also very optimistic. In a CIMS report, it was mentioned that Dr. Li Xiangyu, one of the three experts from Boeing, the initiator of the step standard, after watching the step standard research and development promoted by the CIMS group, believed that "in terms of research level, China is second only to the United States and higher than Europe. Honeysuckle system software (Note: developed by Beihang) meets the step standard and is the highest level".

For a time, China's independent CAD industry felt that it was also worth singing and dancing. You can pour a cup.

Elegy of Sheng Ju

The feast was celebrating and singing, and a sad song suddenly came out of the window. China's CAD has made a good start in the first 20 years, but I didn't want to fall into a big somersault in the subsequent 3D CAD market, and suddenly walked from sunshine Avenue to cliffs.

From April 1999 to April 2001, the acceptance of the local special topic of "national CAD application engineering technology development and application demonstration" was completed. On June 26, 2001, the Ministry of science and technology held the acceptance meeting of "national CAD application engineering technology development and application demonstration". So far, the vigorous "CAD application engineering" has completed its historical mission.

Since then, the situation has taken a sharp turn. Looking back on this period of history, although it is only a short 20 years and a personal history, the parties are still in front of them, but current events are in a trance, and it is inevitable to feel the paradox of history.

In 2002, the state proposed to develop new industrialization and promote industrialization with informatization. All walks of life ushered in the opening year of manufacturing informatization project. The manufacturing informatization in the tenth five year plan began with "seven R & D fields, especially 863 R & D projects related to manufacturing - 3D CAD, MES, ERP, enterprise integration system, network manufacturing, CNC equipment and database management system". In these seven key areas, 3D CAD represents the development direction of digital design technology, and the microphone is transmitted to 3D CAD.

However, the microphone began to stop making sound.

In the era of 3D CAD, two things have changed fundamentally. One is technology, the other is market. The technical threshold of 3D CAD is still quite high. A variety of in-depth basic technologies such as modeling technology, geometric modeling technology and rendering technology also need to support strong system design ability and product ability in order to go to the market. This requires high-end talents in basic science, intensive labor and long-term investment. Another subtle cut is the entry threshold of 3D CAD market. For China, which has just entered the WTO, foreign new products are pouring in like a tide. China has selectively liberalized and defended, but some dead corners have not been taken into account. Industrial software bears the brunt. It can be said that China's three-dimensional CAD software seedlings are facing three mountains: high-end mature software, pirated near zero cost software and "foreign wolves" brought by a large number of foreign manufacturers at the same time.

The foreign wolf pack consists of main engine factory, supporting equipment and supporting software. The goal of "market for technology" that China has been discussing is too focused on the main engine factory, and many technical advantages are hidden in the other two corners, which makes it difficult for Chinese independent manufacturers to squeeze in.

When the teachers and students of several domestic aviation colleges and universities are still exploring 3D CAD algorithms, with the needs of Boeing subcontracting production, made in China increasingly needs IBM's high-end design ability of hardware and software bundled together. In 1986, the mainframe computer IBM 4341 was introduced by 625. It has a set of 5080 color graphics terminal processor system and installed a user's mainframe version of CATIA v1 0 At the beginning of 1988, 603 introduced IBM 4381, with five 5080 graphics systems and related CATIA software. These easy-to-use software brighten the eyes of engineers. With the higher and higher requirements for 3D, Boeing has higher and higher requirements for domestic subcontracted parts, and the data package must be usedModelDelivery, and domestic software can not meet the requirements at all.

Therefore, China's industrial software was forcibly closed and directly erased from the supplier directory. This is the most typical young industry that has been washed out after China's entry into WTO. At that time, we didn't know how to protect industrial software.

However, looking back, it seemed that there were many two-dimensional CAD companies in China at that time, which was only a superficial prosperity. For the development of 2D CAD, on the one hand, the "drawing board" is deeply rooted in the hearts of the people. Decades of industrialization has accumulated a large number of designers, draftsmen and workers who draw and read drawings, which has made the "CAD application engineering" with the slogan of "drawing board" in brief achieved immediate communication results. On the other hand, the initial technical threshold is low. Individuals, colleges and enterprises with certain technical ability can quickly develop available two-dimensional CAD products and form a large number of contestants in a short time. Especially the secondary development based on foreign software has also formed a seemingly good market.

However, when we really want to achieve commercialization and "easy to use", we need a good user interface and pre-processing ability, foreign two-dimensional software presents great advantages. This is the real meaning of industrialization, not the breakthrough of core technology, but the stability and ease of use of engineering. This is the biggest weakness of technological innovation in Colleges and universities. The same technology from universities can have a good business transformation mechanism in the United States; In China, there are few successful cases of university entrepreneurship. With high-tech professors in their hands, their entrepreneurial ideas are not much higher than those of reckless heroes, and the result can only be a chicken feather. After all, only core technology is far from real entrepreneurial success.

The secondary development based on foreign software is a super trap for the independent development of industrial software. Many CAD foreign businessmen enter the Chinese market by the wave of "secondary development", and cultivate a climate, which is difficult for end users to part with. At that time, Autodesk and other manufacturers supported a large number of secondary development integrators, and soon formed a scene of "secondary development upside down" in the industry. It has formed a deep-rooted ecology and gathered the wisdom of many secondary developers on the interface of foreign software. Compared with young independent developers, it has an overwhelming advantage. Users are naturally happy to eat such fruit, and are very addicted, forming a strong dependence on foreign software.

However, the property rights of secondary developers often fall into the hands of foreign manufacturers. For such developers and integrators, the day is "laughing in the first half and crying in the second half". Similarly, integrators who need to invest a lot of energy in secondary development are a very sad situation. They can only eat the soil flying in front, can hardly form a brand premium, and it is difficult to control intellectual property rights; Every day I help others build skyscrapers, but I become the bottom brick. Some foreign software companies will adopt very covert "pinch people", suppress traditional large software integrators and support smaller and more obedient integrators. China's private software agents are always little carrots, and it is difficult to devote themselves to the revival of independent CAD industry.

In the face of the most common idea of "integration before autonomy", people in the industry are forming a consensus, which is a dead end. When we embark on the road of integration, we are basically unable to make our own decisions. There are no shortcuts, no curves. Fortunately, there are also those who insist on no regrets. No matter how difficult the independent road is, we can no longer develop independent CAD through "secondary development" and "agent integration".

The road of independence has always been difficult, and it is basically a bitter history. After flashiness, those CAD manufacturers who were once active on the stage began to close down one after another. Among the five initial members of the domestic CAD alliance, only Wuhan Kaimu is still in existence, but CAD is no longer the main business.

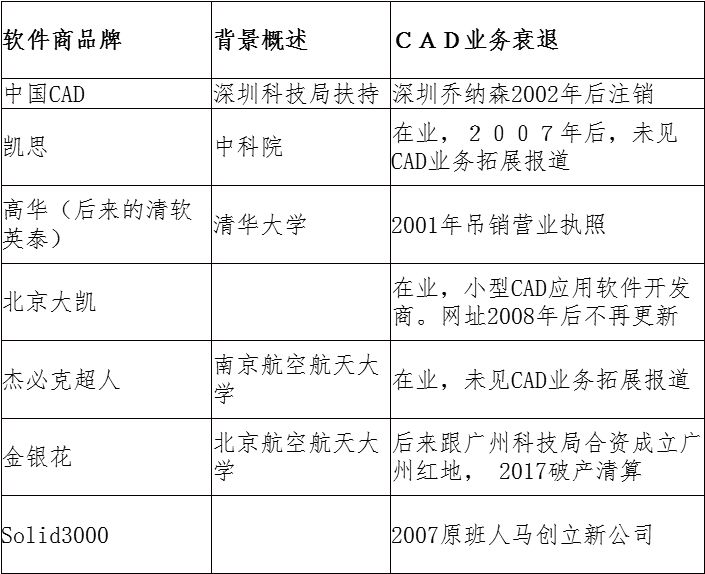

Table: withering CAD independent manufacturers

(compiled by Nanshan Institute of technology according to online public information)

Industrial software is a typical "user used" technology. Without the nourishment of users, software cannot develop. Most of the fallen industrial software suppliers in China starved to death because of the lack of nutrients from users. Zhongke Fulong, hatched from the Chinese Academy of Sciences, has cooperated with Sinopec Beijing Petrochemical Engineering Company and Yangzi Petrochemical Design Institute since 1995, so that the two teams of software development and engineering design nourish each other. Later, it has been closely bound with China Petroleum and chemical survey and Design Association, which makes it still occupy a place in the field of petrochemical pipeline design. In other words, they survived side by side with users and relying on the domestic market. The CAD software in the construction field (now known as building information modeling BIM software) also enables end users such as bridges to stand beside domestic software developers because of the mandatory standards of the Ministry of construction in the past, leaving some BIM software providers such as PKPM, Guanglianda and Luban.

There are some lucky sites in some parts of the construction industry. In fact, there are not many such scenes. Many software companies have to embark on the road of opening up markets abroad. This forms one of the strangest increasing paths of "user contempt chain" of industrial software: overseas users have the lowest degree of contempt, and often take the lead in using Chinese CAD software, followed by domestic foreign-funded enterprises, then domestic private enterprises, and finally state-owned enterprises. In fact, it is our state-owned enterprises that most "discriminate" against this industry.

However, companies that follow this disdain chain to tackle key problems independently, such as Guangzhou Zhongwang, Shanghai Wangyou and Suzhou HaoChen, have made great achievements in the journey of expanding the market. Foreign sales can even reach more than 30%, which in turn has won the attention of domestic enterprises.

There are also good fruits on the cliffs. It is also true that there are still kindles of 3D CAD in China, such as Guangzhou Zhongwang, Huatian software and digital generous, which are valuable opportunities at present.

The commercial environment of CAD in China has always been a huge weakness. So far, there are still many famous technical heroes, but it is a pity that they have not been able to turn such academic achievements into commercial software. A new CAD product or new version on the market is generally not easy to be accepted by the majority of users immediately. There is a long running in period, which makes the return on investment very slow.

Professor Tang Rongxi of Beihang is an enlightener who has promoted the development of China's CAD / CAM industry. In addition to a lot of technical promotion, his enlightenment and attention to the whole industry have taken care of the growth of a seedling. As early as 2006, he reviewed the development of China's CAD software industry, and pointed out that China's CAD industry is still a delicate seedling. Unfortunately, even after 13 years, this judgment is still valid.

Only by infiltrating a national strategic intention can this young seedling have the opportunity to grow.

Do you want to attack the mountain?

The characteristics of industrial software represented by CAD can be summarized as "extraordinary Five Finger Mountain", which has five extraordinary points. First, the output value is very small and almost invisible. This industry adds up to 20 billion; Second, the development time is very long and the investment is very high, which exceeds the imagination of ordinary people; Third, it plays a very important role. The indirect pulling effect on manufacturing is more than 100 times, and the leverage effect is very obvious; Fourth, the value is very hidden, and people who do not deeply understand the manufacturing industry often do not perceive it; Fifth, the software and users are very close and cannot be separated. This means that industrial software cannot be developed simply from suppliers without the support and cultivation of users.

These five almost contradictory "very five finger mountains" are reflected in the "wonderful industry" of industrial software. Only by deeply understanding the value of industrial software can we form the thinking of complete industrialization.

Can the withered independent CAD industry bloom again? It is very complicated to answer this question, because the international trend is that CAD is no longer a simple CAD, but combined with simulation and even with the Internet of things. As a simple tool attribute, CAD is retreating faintly; The platform strategy is becoming more and more obvious. However, behind the platform are tools. Just like opening 007's cool and handsome exterior, it is full of loaded weapons. As the internal foundation of software tool attributes, whether CAD, EDA or CAE, China, a large manufacturing country, should take a clear-cut stand anyway.

At present, the domestic construction of domestic 3D CAD shows many questioning attitudes from the perspective of the high-level expert group of ministries and commissions. Some people think that China can never make a CAD system, and some people think that CAD system is not so important. These experts are probably shrouded in the experience of past failures. However, many of the hills of China's industrialization have always been a bitter situation of repeated wars and defeats. The hills that can not be attacked for a long time can never stop the pace of attack.

Although the development of domestic CAD feels suffocated, there are also many happy highlights. The 2D products of HaoChen software have achieved good benefits through the strategy of "overseas first and then domestic"; Among the 4.5 million apps in China, the download volume of CAD mobile phone drawing version software has actually entered the ranks of the top 600, which is worthy of the name of "king of industrial app". On this route, it is far away from the invincible two-dimensional King: AutoCAD. Huatian software has created a new way in the integration of design and manufacturing of petrochemical static equipment and long-term archiving of three-dimensional data; Zhongwang acquired American 3D CAD ten years ago. After years of digestion, it is gradually showing a positive chemical reaction.

It seems that even the iron stew pot should try to lift it from all angles. It's not easy to open it as a whole, but we always have to move it left and right. If all parties breathe out, it will have a chance to be opened.

Notes:Iron blood is not cold, iron armor is still there

If you survive, you have a chance. In recent years, a chairman surnamed Ling of electric CAD Lichi has insisted on going to the enterprise site to preach the opportunity of electrical digital transformation every week, giving nearly 200 speeches. Ritz has only one goal: a German electrical design CAD company. There is nothing else in his eyes. This dedication to the goal can be summarized as a four character idiom of China's industrial software: "Lao Ling preaches". Laoling sermon is an epitome of Chinese industrial software programmers and entrepreneurs; Laoling's sermon is a portrayal of the life and death of China's industrial software. Behind many leading foreign software giants, there are one or two thin domestic figures in the distance. This is the most vivid trailing scene. The small tail that can't be thrown off leaves a weak but long-term option for adventurers looking for a spare tire.

Veterans have not left the battlefield, and veterans are still fighting, which is a precipitation of industrial experience. Because of their existence, this flame carrying hope hovered in a dark sky, half dark and half bright, and never left.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853