-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2101

The collision moment between the torrent of internationalization and the countercurrent of globalization will have a profound impact on the development pattern of China and the world.

In 2001, China's manufacturing GDP accounted for only 20% of that of the United States, a year after China's accession to the WTO; In 2010, China's manufacturing GDP caught up with that of the United States; In 2018, China's manufacturing GDP was basically the sum of the second, third and fourth place in the United States. Made in China has benefited greatly from its integration into the torrent of internationalization. This interaction benefits and becomes a force widely promoting global development.

Figure 1 Changes in 20 years

Now, it is not only the economic and trade friction and scientific and technological war between China and the United States that have brought great shock, but also European countries and Japan have strong demands for manufacturing back to shore. In other words, from global manufacturing to intercontinental manufacturing and local manufacturing has become an emerging new scene.

In the past 10 years, the world highly recognizes this trend of internationalization, so Chinese manufacturing enterprises are just like taking a high-speed train and following.But now it's different. In the past, many conditions used to be changed. The high-speed train is going to climb the mountain now, and severe bumps are beginning to appear.

The reason why there is a saying of "great changes in a century" is that local points are evolving, the elements of various collisions have not been completed, harmony and balance, and the decisive force has not yet appeared. The torrent of internationalization and the inversion of globalization are at a fierce intersection.

What position is made in China in such an uncertain game? There are three parts of the global supply chain: North America, Europe and Southeast Asia plus China, Japan and South Korea, which constitute the support of a stable global supply chain.The most impressive thing is that made in China has surpassed the world factory.If made in China is just assembly and assembly, there will be many unsolvable phenomena. Some supply chains made in China will find it difficult to move out when they are under external pressure.

In an interview a few days before taking office, the new Japanese Prime Minister Kan Yiwei mentioned a very shocking thing, that is, made in Japan is so dependent on China. The prime minister will be shocked by this, and we will feel very "shocked" because this is not only now. In fact, around 2012, the Japanese industry put forward "China 1", and the core idea is to copy a set of supply chain outside China. But now it seems that Japan has failed to do so. In this epidemic, Japan relies heavily on the assistance of China's masks and medical equipment. The situation is critical, making the phenomenon of "over dependence on China" too conspicuous. Therefore, the shock of the Japanese Prime Minister can be seen as a gesture echoing public opinion.

This is because made in China has long changed from a world factory to a super node of the supply chain. A large number of imported and exported products present a viscous mixture.Under the protection of this super node, we can see that this is China's supply chain, which shows a very strong toughness. This is the moat made in China. Of course, it is impossible to answer how long the moat can provide security, because there are many unknown potential forces that will also work.

In the past two years, South Korea, Japan and European and American countries have greatly increased their investment in India and Vietnam, such as Thailand, Malaysia and Indonesia. In the second quarter of 2019, China's exports to the United States decreased by US $36 billion, of which 60% and 70% were undertaken by Vietnam. Although Vietnamese manufacturing is still very dependent on China's semi-finished products and raw materials, the growth and decline of these supply chains cannot allow it to develop freely. China needs a complete supply chain system layout, which I call "China's supply chain offensive and defensive war", which requires in-depth deduction from the industrial system.

It can be seen that there is a clear moat on the periphery of made in China.

Let's briefly talk about the interior. China has a middle class of 400 million people, close to 500 million people in the EU. It is a huge high-quality consumer market. Among them, there are both visible wishes, such as good toilet or electric rice cooker and milk powder; There is also a kind of mind that can't be guessed. After the birth of many products, they have been unexpectedly sought after, such as Tesla electric vehicle. This also shows that we can't see through the consumer psychology of the 400 million middle class, and there is great potential to tap. All these need high-quality manufacturing in China to keep up as soon as possible. This is also an important ballast at the present moment.

In the post epidemic era, China's supply chain is still very stable, because the current industries in various countries have not recovered. However, after that, the speed of supply chain reconstruction will still accelerate, and countries will find that supply chains cannot be put in one basket. China now has certain advantages. We should think about such problems first.At such a moment, looking at such a problem from the perspective of supply chain offensive and defensive war may be more in line with the current situation.

Made in China has several tough battles to fight.The focus here is on "new quality thinking".

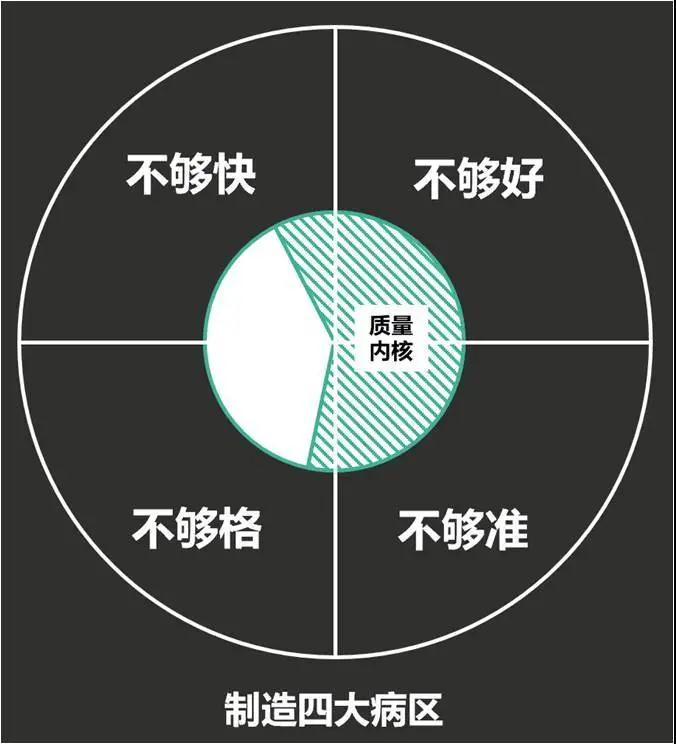

The problems encountered by made in China can be divided into four categories.

The first is "not good enough".This is the most common complaint about quality. The product is easy to break and the performance is not up to standard. Many people's understanding of low-end manufacturing is often concentrated here. This understanding is also easy to form a conditioned reflex, which is actually very unfair to the rapid development of Chinese high-quality brands.

The second is "not accurate enough".The product quality is very good, but why don't you buy it? This means that there is a lack of awareness of product positioning and insufficient user experience. If you look at the quality and specifications, they basically meet the standards, but the customer just doesn't buy them.

Recently, I bought a bottle of olive oil produced in a northwest province. The taste is still very mellow, but the experience is very bad. It is packed in square tin cans. But the lid of this bottle is relatively short. After unscrewing it by hand, you will get a hand of oil. Every time you pour it out, the excess oil will surround the square area above the packaging bottle, leaving oil storage, which feels very unsanitary. This brand can't be remembered, but after this hand oil comes down, I specially remember this brand, that is, I can't buy it next time.

It should be said that the manufacturer basically has no judgment on the user's mind, but only focuses on the product itself.

Figure 2. Four products made in China

The third is "not built fast enough".Can create some high-end products, but the speed is particularly slow. For example, the annual output of China's regional jet ARJ is about 10. What is the most advanced manufacturing level in the world? In 2018, the main models of Boeing and Airbus produced 55 aircraft every month. This is a very amazing gap.

The fourth category is "not qualified enough", in fact, it can't be made.Many "necks", or short boards, appear here.

If we carefully investigate these four types of sectors made in China, we will find that they have something in common, that is, the "quality core". If quality is regarded as the leading force, 70% of the problems made in China can be solved.

At the moment of internal and external pressure, it is necessary to promote China's high-quality manufacturing. The core point is that entrepreneurs need to take "quality thinking" as a bottom line thinking, rather than whether they can learn or not.It can be said that this bottom line thinking is "suitable for any time, any enterprise and any manager".

Quality and industrialization are intertwined like a double helix like DNA.In the whole process of industrialization, the theory and tools of quality are also changing, and the quality thinking of entrepreneurs also needs to change.

The earliest germination of modern quality depends on measurement. In the handicraft age, there was no need to measure. It's ok if it's easy to use and enough. The quality of bronze tripod or sword casting depends on the sound of fingertips. If it's crisp and pleasant, it can show that the quality is good enough.

The industrialization of modern quality starts from testing. As early as before and after the American Civil War, the interchangeability of parts of gun machinery made the "detectable" quality more urgent. At that time, guns were made by one person, and their guns were completely different. The parts were broken, so the whole gun had to be thrown away. Whitney invented the gun with interchangeable parts, which has a far-reaching impact on the later quality development.And quality is importantSex began to emerge in the form of "interchangeability".Interchangeability involves the consistency of specifications, which puts forward very high requirements for measurement.

Later, the Ford assembly line became an integrator, sending the quality problems to the high-speed conveyor belt for inspection, and the parts must be universal and can be used when they are picked up.

Then, mathematics began to play a role. Some data tools based on statistics enabled quality prevention by measuring limited parts. Shewhart, who invented the statistical tool SPC, is known as the "father of statistical quality control". At this time, "consistency" has become synonymous with quality, even until now. Even today, statistics is still regarded as the main quality control tool in factories. It can be said that this is the product of industrialization hundreds of years ago. This has also caused the shadow of quality vulgarization.

Then, there is the experimental design. Through the combined test of the key factors affecting the quality, we can find the best parameters to control the quality. This method first appeared in the field of agriculture, and later Dr. Taguchi of Japan introduced it to the manufacturing industry on a large scale, which played a great role in the improvement of Japanese manufacturing in the 1970s and 1980s. This is called "Taguchi design", which was later systematically transformed by Americans into a school of "robust design", which deeply influenced the era of socialized mass production.

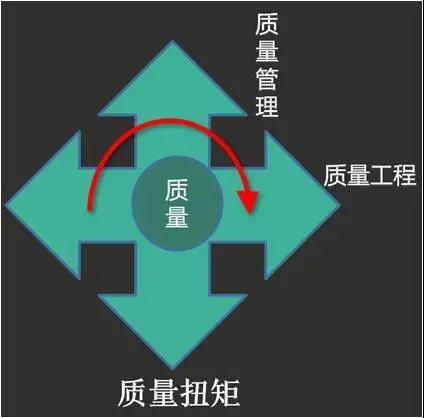

The above are the development of quality engineering, and quality management is also advancing at the same time. From Taylor's time management to GM president Sloan, who competed with Ford, his invention division and independent quality department have deeply affected the organization of large enterprises. Dai Ming, an American scholar from the field of statistics, has deeply influenced a large number of managers in Japan. Since about 1947, Deming has trained nearly 80000 middle and senior managers in Japan ten years ago. Coupled with the later Julan, it can be said that the raging fire of quality management was widely ignited in the Japanese manufacturing industry.

Quality engineering and quality thinking are intertwined, which greatly promotes the quality level of manufacturing industry.It can be said that quality engineering is the capital word "I" in China, while quality management is the Arabic word "1". The two work together to form a powerful qualitytorque。The rise of manufacturing industry in any country is inseparable from such a cross quality torque.

However, when there are many quality tools and methods, and specifications are regarded as the first importance of quality, the problem of "quality vulgarization" also began to appear.Many factories only pursue quality specifications, while the quality department strictly follows the standards.However, if the quality problems are all under the pressure of the quality department, the quality behavior will be highly dwarfed. Because many quality problems do not come from manufacturing, but from design.

In the stage of concept and design R & D, it accounts for only 8% of the cost, but in fact it determines 45% of the cost. This means that the quality gate must move forward and enter the design end in order to better hold the gate. This is why after the wide implementation of Six Sigma, there will be six sigma DFSS for design. The former is oriented to manufacturing process, while DFSS solves manufacturing oriented design. It is to solve quality problems, but the balance point of quality thinking has moved forward.

Now there is a problem in the electric vehicle industry“Tesla paradox”。 Although Tesla is popular, its quality index doesn't look good. In the quality ranking of J.D.Power, an American consulting company, it ranks the last. 250 quality problems of 100 vehicles; The best dodge and Kia have 136 problems in 100 cars.

So why should everyone buy Tesla?

It can be said that it makes an accurate analysis of the needs of users and abandons some requirements of quality specifications. For example, Tesla's body should be made of cast aluminum integrated molding, which is first for portability and second for large-scale and rapid production. But once the car body is damaged, it is actually very difficult to repair. Is this information important? Very important. Therefore, the manufacturer will make very detailed regulations on the specifications of the car body and strictly implement them. But if automobile manufacturers have a deep grasp of users, they will find that there are more important things. For example, more emphasis is placed on remote software upgrading. Upgrading software every year can increase the experience.This insight into users is sometimes more important for quality than adherence to established specifications within the factory.

If you simply entangle the specifications, there will be the result of quality dwarfing. From this point of view, Tesla paradox is difficult to explain.

Even in familiar areas, redefining products will naturally redefine quality.

If we want to think carefully about the high-quality life of 400 million people, all products may be redesigned. A domestic start-up in oral care challenges the most neglected toothbrush industry. It selects ultra-fine bristles as the entrance of high-quality products. Because the super brush will make the gums care more convenient, which requires a gentle and awesome brush.

Strangely, this cutting-edge toothbrush enterprise can't find this raw material.In Hangzhou market town, Yangzhou, Jiangsu, known as the "toothbrush capital", 30% of the toothbrushes in the world and 80% of the toothbrushes in China are produced here. But even so, no one can provide such bristles. The toothbrush company had to find the economic manufacturer of this sharpened wire, Toray, Japan. However, due to the unique product design features, such as the hidden injection port (this is to make the toothbrush rod look like a natural refined product), the ordinary toothbrush factory can not manufacture it. Finally, I found a toothbrush OEM enterprise of European toothbrush in China. This start-up toothbrush enterprise has achieved great success. The sales volume of its first product exceeded 50 million in half a year. Even the most famous injection molding machine in Germany later exhibited this toothbrush on its own booth to prove that its machine is a guarantee of high quality and high quality.

It can be said that entrepreneurs have adopted a new product design concept and reshaped the cognition of product quality. Its biggest feature is that it fully considers the feelings of users, introduces the medical concept of dental care into product design, and comprehensively defines quality.

At the same time, in the digital age, mass torque begins to be accelerated.The two most important energy magnetic fields are digital technology and the Internet of things.It has made many amazing changes in the quality scene.

People are the most creative, but often the most unreliable factor in quality. With the progress of technology, many on-site manned links are being gradually replaced. For example, in the process of machining parts, it is often necessary to stop the machine tool and open the door for workpiece measurement. After the data is given, the machine code is regenerated. There are not only the factors of low machine efficiency, but also the errors caused by human measurement, resulting in cumulative transmission. Now, the probe and the tool can be installed on the same fixture. During the middle process of tool machining, the probe can be automatically changed to measure directly, so as to generate the next tool machining path.

Figure 4. Improving quality of on-line measurement (source: Beijing precision(carved)

This approach is to replace the traditional ruler and gauge with digital tools. The action of manual measurement is completed by machine tool measurement, and the process of manual recording and judgment is realized by software judgment. Due to the reduction of human error, the quality is also greatly improved.It can be said that instead of looking for experts in quality control, it is better to measure the new model. This is the change of quality thinking caused by on-line measurement.In fact, a large number of measuring equipment are moving towards online real-time measurement, which also makes the whole line detection of parts possible. These applications in the digital age are challenging the traditional quality thinking.

At the same time, the design simulation optimization technology can also greatly accelerate the on-site process design. For example, some body quality problems in the main engine factory are often determined by the basic point of the die and fixture, the position of the reference system, and the stress. How to determine the position of the fixture? In the past, it was often completed by doing experimental design doe, and then simulation. The side of the body is equipped with 10 parts, and each body part has a positioning circular hole, a waist hole and three clamping points. Plus the x-axis and y-axis, there are about 100 variables in total. If the traditional calculation method is adopted, the calculation times will reach the amazing number of 172 power of 10. This is completely impossible to calculate, which is also called "big variable curse".

However, with the technology of artificial intelligence, through mathematical modeling and optimization simulation, the final calculation point can be reduced to about 10000 times. Moreover, the quality is also improved, and the sum of Six Sigma at 224 measurement points is reduced by 65%. This is digital technology, which enables and improves the traditional DOE method.This also means that the quality thinking of the manufacturing industry must be further improved to adapt to the changes of the digital age.

Digital operation and maintenance also provides a rearview mirror perspective for quality thinking. Komatsu, the world's second largest construction machinery factory, has built an industrial Internet platform for all construction machinery in China and placed it in Shijiazhuang. If the excavator on site has a fault, the platform will give an alarm, and then the maintenance service center will deal with it. The data on this platform soon attracted Komatsu's attention. In fact, many alarms are not a big problem. Only 0.2% of the faults are necessary to go to the site for maintenance. Why is the fault alarm so inaccurate? Komatsu designer did not know such a problem at first. However, with these data, designers can optimize the design of quality margin and alarm margin, so as to greatly save cost.

With the advent of the digital age, there are many ways to improve quality, and it is very important to establish a new quality thinking.

In China, quality is of course an old topic. All people feel that they attach great importance to quality.However, if studied carefully, many enterprises only focus on form, rather than quality as an enterprise management strategy.As for ISO quality standards, in fact, this is only the most basic threshold, which has little to do with high-quality manufacturing. However, many enterprises will take this certification as a show off. This is a big misconception.

This requires the leadership to form an instinctive understanding of quality thinking, rather than just looking at problems at the department level or appearance.

In a sense,Chinese quality actually eats a bowl of uncooked riceAt this point, you need to re fry the raw rice. Don't be afraid to return to pot rice. Delicious egg fried rice is also return to pot rice. The key is to return to the bottom of thinking.

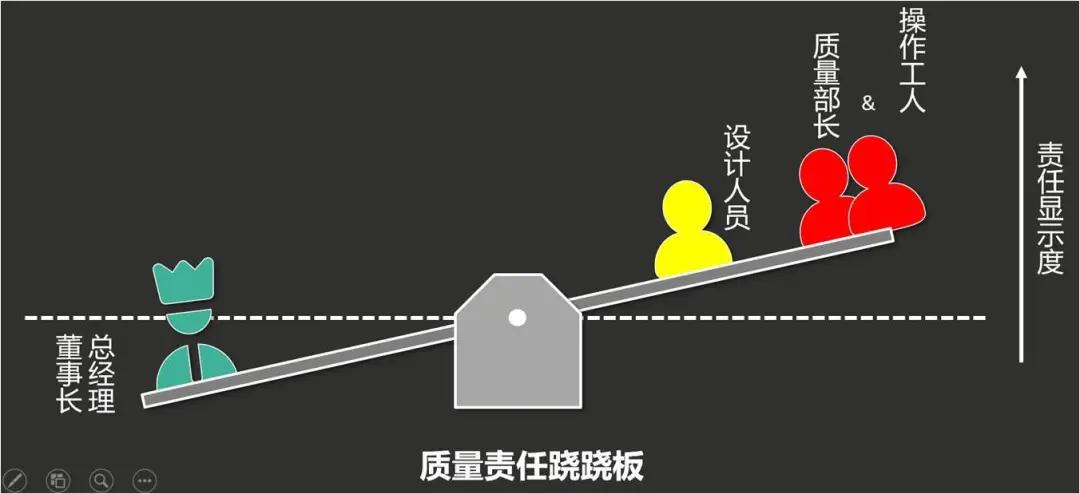

Quality thinking is a kind of advanced thinking, which is very hidden. In the enterprise, it is easy to hand over all responsibilities to the operator and the quality department. As long as something goes wrong, all the boards are hit on it. If you go a little further, you will find the design. But in fact, the people who really deserve to beat the board are enterprise leaders.

Quality thinking must start from the board of directors. It is a very misunderstanding to leave the quality problem to the "craftsman spirit".American quality master clisby wrote a book "quality is free" to the effect that it is easy to achieve high quality without spending a lot of money. However, there is a premise for this understanding, that is, the cognition of entrepreneurs must cross an epiphany platform. After that, the cost of quality will be greatly reduced or even free; Before that, quality was still very expensive.

Because entrepreneurs' ideas must be nurtured to form well-trained quality thinking. The quality culture of the whole enterprise can be fundamentally improved. Six Sigma first came out of Motorola, but it is people like Welch, President of Ge, who really carry forward it. Only when leaders can understand, can the whole quality thinking rise to a higher level.

New quality thinking and reshape the bottom line thinking of entrepreneurs.On the one hand, it will lead users to enlarge demand capture, make full use of big data, customer portrait, psychology and other comprehensive methods, so as to make the product unique charm effect, not just the traditional quality reliability index. On the other hand, make full use of digital tools to mine and make full use of the data of previous and present lives of products as design input to predict reliability and life cycle; At the same time, the process is handed over to the intelligent machine, and the optimal control is carried out every minute to ensure the stability of the process.

The history of quality development is a history of quality thinking moving forward. From site to design, from engineering to thought, the quality gate has moved forward. If the big bang 13.7 billion years ago was the starting point of the universe, then for an enterprise, the place where the big bang occurred should be in the chairman's mind, which is the source of all energy. An enterprise's quality thinking needs to push the starting point to the office of the board of directors. In response to the current more complex situation, the new quality thinking can be said to come roaring at the right time.

Made in China must make a lot of breakthrough progress from imitation to micro innovation and then to originality. For entrepreneurs, new quality thinking bears the brunt.Quality power, focusing on the mental breakthrough of the first leader; At the time of the National Games, we need to reshape the quality bottom line thinking of entrepreneurs.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853