-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2783

Industrial cluster is the skeleton of made in China

The most obvious feature of China's private manufacturing industry is the county economy. In more than 3000 county-level cities and subordinate towns in China, there are active manufacturing communities in batches. This is the familiar industrial cluster. From the fireworks coming to Yangzhou in March, the beauty of Yangzhou is not in vain, but also can be played and sung. 70% of the output of Chinese zither comes from Yangzhou. The feed manufacturing and forging machine tools here are also unique in China. As a big GDP Province in China, Guangdong has many industrial clusters. Zhuhai's printing consumables industry supplies nearly 80% of the world's color ribbons and 70% of compatible cartridges. The hardware locks in Xiaolan Town, Zhongshan City account for more than 50% of the national market. Small towns carry an amazing accumulation density.

In addition, Shandong, the third largest GDP in China, is also diverse. For example, there are nearly 400 processing enterprises in Heze, with an output value of more than 20 billion yuan. This is a really flat place. The coffin business is the first in the world. 90% of Japanese coffins come from Heze. Similarly, in Shandong Province, it mainly plays guitar instruments, and electric guitar accounts for about 40% of the total output of the country. There are also Shandong Zaozhuang Tengzhou machine tool cluster in southern Shandong, with a variety of small and medium-sized machine tools. China has the most complete industrial category system in the world, while Shandong has the most categories in China. Such a complete business form is closely related to these various industrial clusters. Zhejiang, on the other hand, has always been famous for its blocky economy. The pen makers in Daxi Town, Wenling, Xinchang County, Shaoxing, and Fenshui town, Tonglu, Hangzhou have their own merits, and Yiwu lighters have spread all over the world (although the real production base of lighters is not here). The four provinces with the largest GDP in China have many manufacturing industries in the form of industrial clusters, which is the same in other provinces.

Industrial cluster is the skeleton of made in China. Its shape determines the appearance of made in China, which is the biggest national condition of China's industry.

A living fossil, made in China, evolutionary history

Over the past 40 years, many clusters have formed spontaneously and rapidly rooted and grown. Among them, the role division is orderly, which can not only clearly see the fresh vitality of entrepreneurs bumping around and finally killing their blood, but also find the knowledge chief who clearly represents the origin of technology. Another distinctive feature of this is that grass-roots officials touch the border everywhere and there are traces of policy deregulation.

Next to xiong'an, there is an industrial cluster that has been famous for many years, with an output value of nearly 50 billion yuan. This is the luggage capital of China: Baigou, Hebei. Surprisingly, this is an immigrant town. The population is less than 200000, 2 / 3 of which are from Henan and Guangzhou. It can be said that the whole people are businessmen. It is a real business town. If you have in-depth contact with the local grass-roots government departments in Baigou, you will have a different understanding of the strong vitality of China's grass-roots cadres. Entering the office of a local director in charge of Industrial Science and technology development, there is a humble small bed in the office of less than 10 square meters, which is prepared for sleeping in the office at any time. A director of the Bureau has to play more than a dozen different roles at the same time, which is really a model of streamlining troops and administration. The director was very familiar with various enterprises and came immediately. Over the past 20 years, we have witnessed the rise of the Baigou generation, and now it continues to grow with the new generation. From attracting investment, to cross-border trade, to expert dialogue, and even live delivery, there is no doubt. Grassroots officials are really a Swiss Army knife, proficient in both literature and martial arts.

If we have a more detailed understanding of the 30-year history of Baigou's development, we will find that this is really a sample of "ideological emancipation". If there were no grass-roots officials who ran into walls and tried to break through the border, it would be difficult to develop into the current scale. Baigou, relying on the self hematopoiesis of a township, vividly picked itself out of Gaobeidian and upgraded itself. In 2010, Baigou became a direct administrative county town of Baoding city. Is this little Shenzhen in the north? Scientific and technological innovation is naturally incomparable, but the ideological emancipation and national vitality of immigrant cities here will inevitably remind people of Shenzhen.

Where there is ideological emancipation, there will be a fountain of vitality. Industrial cluster is the centralized ejector of individual vitality stimulated by the people.

There are other clues to the source of technology. If the source is traced, it is generally from the technical backbone of state-owned and collective enterprises in that year. Sunday engineers are the most typical enlighteners. In many industrial clusters, such as the dryer cluster in Changzhou, the foundry in Zhuhe Town, Liyang, Jiangsu, or the pen industry in Zhejiang, we can see the shadow of the former engineers tutoring one or two intelligent prophets to make preliminary exploration. When the family made a appearance and made achievements, the whole village began to be involved one after another, forming a situation of catching up with each other. The industrial fission has rapidly spread to the whole village, even to the external villages and towns.

The development of industrial clusters has experienced five stages. The first is knowledge kindling, which is the sporadic release of the industrial system in the 30 years since the founding of the people's Republic of China. During the period of reform and opening up, of course, a group of farmers happily embarked on the land, while another group of people who wanted to change the form of farming embarked on the stage of manufacturing. Their director is a small technology pioneer of state-owned enterprises. They ignite people's desire with spark. In the second stage, in the 1990s, the state-owned manufacturing system turned to the collective economy, and the engineers of state-owned enterprises became the main technical force of industrial clusters at that time. Like a big granary suddenly opened, a lot of potatoes, corn and peanuts scattered everywhere, crowded with each other and not too far away, which laid a distinct foundation for the localized development of industrial clusters. This is the most critical moment. With the technical polishing of this decade, the ship can go to sea. With the help of WTO, it sailed to the international market in 2001.

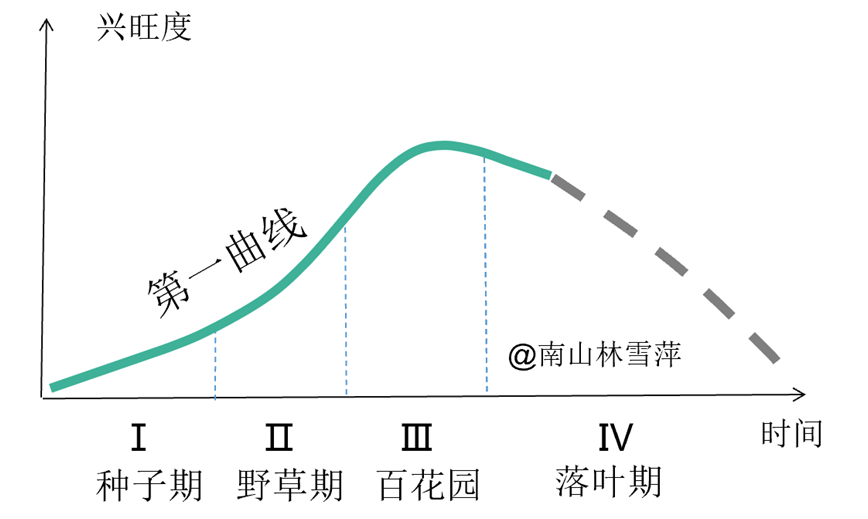

Figure 1 five stages of China's industrial cluster development

In the third stage of globalization, the ecology of industrial clusters has been well regulated. Around 2010, e-commerce is becoming a leading channel of industrial clusters, which is a stage of barbaric production. It focuses more on marketing and understanding of e-commerce forms. During this period, the "Taobao brand" that stood out from Taobao and tmall stores became a new brand force, such as handu clothes house and three squirrel nuts, which benefited from channels and local industrial cluster resources. A large number of micro brands have sprung up, even creating emerging industrial clusters. Guanyun County, Lianyungang, Jiangsu Province is the base of China's fun underwear. There are more than 20000 people in the garment production and processing industry, with an output value of more than 3 billion, accounting for more than half of the mainland market share. This is an accelerated fetus. Without e-commerce, such an industrial form is unlikely to rise on the conservative land of China. This form of e-commerce is emerging one after another. After Taobao and Jingdong, the sudden emergence of pinduoduo has continuously lowered the manufacturing lower limit of China's industrial clusters. As long as you do a good job in marketing, you don't worry about selling goods. The emergence of the epidemic in 2020 made the live broadcast with goods a blockbuster and seemed to become the top of the new generation of e-commerce platforms. In this decade, the industrial cluster of consumer goods has been spoiled by traffic.

Since 2019, made in China has quietly entered the deep bay with turbulent undercurrent. International countercurrent, showing a reverse force of braking. During the epidemic, the super performance made in China and a large number of unexpected and incoming orders seem to relax people's vigilance.

An advanced competitiveness

On the surface, industrial clusters are just a cluster of industries and division of labor, showing the relationship between competitors and suppliers. An industrial cluster is often the leading traction. Jinan information technology industry cluster has more than 170 high-tech enterprises, and the leader is Inspur Group; Yantai advanced structural materials industry group has chemical giants such as Wanhua chemical. It is a common phenomenon to build clusters around the upstream and downstream of large enterprises. These locomotive enterprises can be called anchor enterprises, just like the sea god needle, driving the prosperity and development of the industrial chain.

However, industrial clusters go far beyond this upstream and downstream relationship. In many places, they are often in a situation where there are no heads and each shows his magic power.

Industrial cluster is essentially a kind of advanced production relationship. No matter the scale, it should put production resources and human resources in a narrow space and melt them at high temperature. Therefore, it forms an extreme value network. In Zhejiang Taizhou Wenling Electromechanical market, processing a set of parts is 4000 yuan. And this 4000 yuan, there are actually eight processes, which rely on eight enterprises to complete the processing. Each family can still make money with an average order of 500 yuan. It is hard to imagine this logic of ants' food sharing outside the unique value network of industrial clusters. Perhaps each enterprise only gets a little profit, but as long as this network continues to expand, each enterprise can still maintain a good vitality. You don't have to rely on fertile land, just like the saplings on the cracks of cliffs. A little dew is enough.

These rainwater and nutrients constitute the knowledge concentration of an industrial cluster. On the one hand, it will spread and drive the linkage development of the industrial chain; On the other hand, it will evolve from manufacturing knowledge to user knowledge. In addition to excellence in processing, we should also be very familiar with horizontal knowledge, that is, downstream users. China's shovel is in Luannan, Tangshan, Hebei. The industrial competitiveness here cannot be simply measured by manufacturing capacity, which is bound with user insight. Here is an enterprise that often travels around the world and visits the end-user market, so as to identify the needs of all over the world. For example, French supermarkets love shovel combinations, while Africans love white shovels. Insight into different user needs is a huge market force, while locally, it corresponds to different manufacturing forces. It makes the tentacles of the network of industrial clusters extremely full.

Menopausal anxiety disorder

Most of China's industrial clusters are original ecological development. When it entered the 21st century, it has completed the switching of bones. After two decades of brutal growth, although it seems to be at its peak, it is also declining.

It is not uncommon for industrial clusters to decline. Akron, the tire capital of the world, was first established in 1870 as the first rubber enterprise in the United States, BF Goodrich. By 1935, the city's tire industry had accounted for 80% of the American tire market. At that time, Goodyear, WorldCom, Broadway and other tire giants all gathered here. With the systematic relocation of American manufacturing, this cluster also declined around 1990, leaving only Goodyear tire to become the only local tire enterprise that can not stand. However, "Goodyear", "Firestone" and other names have been integrated into the local streets and residential areas, and become a world-famous brand.

Tianjin bicycle industry cluster was once brilliant. One quarter of the world's bicycles were produced in wangqingtuo Town, Tianjin. But now it is a collective decline. Although the degradation of Tianjin bicycle industry is caused by conservative product ideas, the more fatal blow comes from sharing bicycles. The homogenization of bicycles has created a large number of "uniform" bicycles and destroyed the personalization of bicycle manufacturing. This is the most typical "vulgar" quality of industrialized mass production. It has no personalized charm and only consistent specifications. Moreover, the unstable orders from big to small, coupled with strong and monopoly users (only meituan, Qingju and harrow) and unified maintenance, have dealt a devastating blow to the industry. In the past, there were distributors of bicycles, and there were also many individual shops that made a living by repairing bicycles. This meticulous stratification and rich ecology are all weighed down by the big waves of sharing bicycles. Bicycle manufacturing has completely become an assembly industry without a brand. All this destroyed the bicycle manufacturing system originated in the last century.

Weihai, Shandong, was once a cluster of embroidery products. The embroidery technology inherited from the late Qing Dynasty was finally landed in Wendeng through Yantai. In my childhood memory, every family has a pole support, and every housewife can embroider. Sometimes seven or eight people pick needles together, and the scene of the assembly division fighting at night has become the strongest picture of childhood memory. After China's entry into WTO, embroidery here has moved towards industrialization and continued to flourish. However, in the later era of the rise of e-commerce and low profits in foreign trade, the former hometown of Lu embroidery gradually declined. At present, only one of the four leading enterprises is still supporting, and the supporting factories have basically disappeared.

In this way, industrial cluster is a metabolic organism. It will go through different stages. Without timely adjustment, it will inevitably decline.

Figure 2 growth stage of industrial cluster organism

From the perspective of the current development of made in China to the medium and high-end value chain, industrial clusters as the support point began to be weak, showing a kind of senile disease. As the hometown of pen making, the supporting parts of Fenshui town in Hangzhou, such as hardware and mechanical equipment, have not become a climate. Supporting industries are scattered, and core materials such as ink and refill lack high-end competitiveness; The manufacturing process, such as surface treatment and wire drawing, can not effectively support the industry. Although there are more than 300 printing plants here to do printing and printing, they are only satisfied with simple painting matching. The more advanced manufacturing capacity is insufficient, and no one wants to use these obviously excess low-end capacity to upgrade and turn to supporting processing in other fields.

Hangji, Yangzhou, Jiangsu, is the largest manufacturing base of hotel daily necessities in the world. Hotel daily necessities account for more than 60% of the domestic market. The output of toothbrush accounts for more than 30% of the international market, and it has a monopoly position in China. However, this manufacturing capability can not stand scrutiny at all. In recent years, a well-designed toothbrush brand has emerged in China and won the three major industrial design awards in the world. It also puts forward unique requirements for manufacturing. Whether it's raw materials, wire brushing or injection molding technology, Hangji town can't meet it. When the design requirements are slightly improved, the core competence of industrial clusters will be exposed.

Baigou luggage cluster in Hebei has the same embarrassing situation. The high-end hardware here comes from Guangzhou. The local electroplating process always fails to pass the customs and can not achieve local matching. This is the strange situation of buying gold-plated parts from Dongguan, adding a piece of leather to Baigou, and then transporting them back to Dongguan and OEM Guangdong. Although Baigou is one of the largest bases of trolley cases in China, it is really impossible to make bags of the same quality as xinxiuli. As the most important part of the trolley case - the wheel with bearings, there are few suppliers here. A domestic trolley box that challenges rimowa in Germany with quality has been affirmed by a series of experts such as Hurun, online Red talk show Li Xueqin, who are famous for ranking the rich, but it can not get a supporting supply chain in Baigou.

This is the sadness created by industrial clusters. On the one hand, manufacturing is abandoned due to low-end and labor reasons, on the other hand, high-end manufacturing cannot be done.

When the new domestic products are glowing, the traditional industrial clusters show an ugly belly. It's a sign of aging.

Hangzhou Fenshuiling town is the manufacturing base of ballpoint pens in China, with an annual output of 7 billion, which can meet the needs of one person in the world. As the "hometown of Chinese pen making", the glorious history is nothing to mention. Surprisingly, there are no leading enterprises here. Although there are five or six hundred enterprises, there are only two with an output value of more than 100 million. This scale has long touched the ceiling of industrial clusters. How can we make enough profits and realize self-upgrading?

Sometimes, there are no leading enterprises in industrial clusters, which is deliberately done by entrepreneurs. In Baigou luggage Town, Hebei Province, a large number of rich people hide their output value of nearly 50 billion. However, there are not many enterprises above designated size. Although public figures show that Baigou's luggage output can account for 1 / 3 of the country. But in fact, no one can really find the corresponding company. There are many "underground" factories here, and the manufacturing capacity here is hidden. Many companies continue to spin off the scale of the company and hide in this 27 square kilometer land in the form of small and micro enterprises. At the same time, a large number of outsourcing manufacturing are formed in the periphery. A large number of military factories in Baigou are distributed in the green gauze tent within a radius of 500 kilometers. Why can bags exist in the form of this decentralized corps? The preliminary guess is that the manufacturing process of luggage is very simple and personalized. This means that a large factory is not necessary, and the economies of scale are not obvious. As it has become more and more difficult to recruit workers in the past two years, the number of original factories has been continuously reduced, the relocation of factories is obvious, and the manufacturing soil continues to be lost.

However, this loss of soil may make Baigou at a disadvantage in the future. Even so far, Baigou is still a commercial wholesale base. This is the paradise of businessmen, but it is the grave of entrepreneurs. Only around the business to make money and the lack of a big pattern is the sworn enemy of entrepreneurship. Luggage imitation is so rampant that as long as any designer designs a new product, it will be on the whole market in three days. This means that no manufacturer is willing to invest in the research and development of new products. If you are looking for a style, just go to a large store, which is basically enough, because the rest is basically the same. For industrial clusters, this is a serious involution and self swallowing.

Since the outbreak last year, Baigou has been infatuated with live broadcasting and goods, and everyone and every family will. And the results are remarkable. In the morning, you can go to the trade city; In the evening, handsome men and beautiful women, God's brother and sister, will show up. Because this is the time for consumers to brush video random shopping after work. It should be said that this is a good channel.

But if tiktok looks at the history of the impact of electricity providers on manufacturing, it will find that this kind of live broadcast of Kwai Chi is almost an industrial opium for an industrial cluster. It highly encourages those businesses who are obsessed with working hard on traffic, but basically ignore the basic skills of manufacturing and design. If you stare at me and I stare at you in an industrial cluster, in the face of the powerful platform economy of e-commerce and live broadcasting, there are almost no winners for manufacturing enterprises, and every manufacturing industry is in a bloody battle. Although e-commerce did bring out some new domestic brands, there were few winners and countless dead and injured. These successive casualties are scrambling to extend the lower limit of made in China to the extreme. Spell more, live broadcast with goods, and give full play to the inferior side of made in China. This is a kind of opium that emphasizes business and suppresses industry.

Call for the second spring

After decades of development, the free-growing original ecological industrial cluster has also reached its aging turning point. The most obvious feature is that it pays more attention to sales, price, quality and brand. It is an expert in low-end manufacturing and an outsider in high-end manufacturing. Fierce homogeneous competition has eroded the vitality of industrial clusters. In the hometown of dryer in Zhenglu Town, Changzhou, there are more than 600 drying equipment, and the output value can't do a fraction of that of a Swiss company. It is common to copy drawings and dig heads from each other. Moreover, public service facilities are seriously insufficient, and the effect of "tragedy of the commons" is obvious.

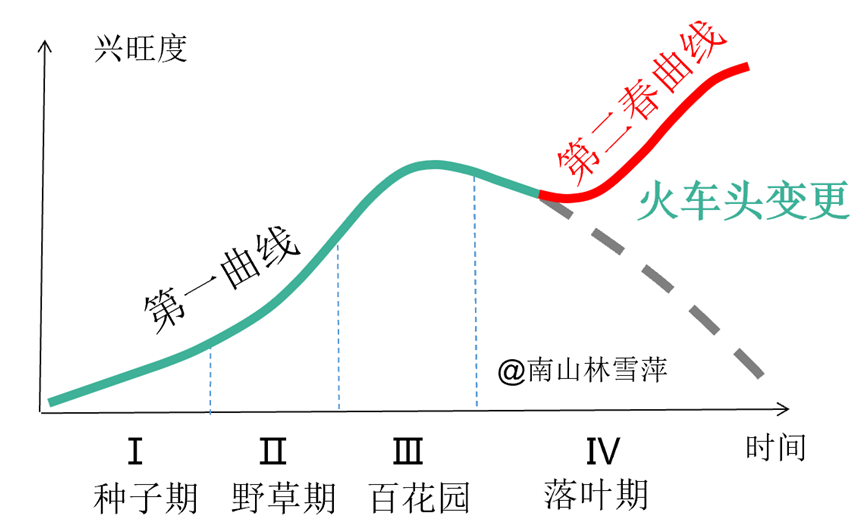

So, how to resolve climacteric symptoms, reverse the situation and find the second spring of industrial clusters?

Figure 3 second spring curve of industrial cluster

The new quality thinking of re designing products for users' feelings is the key thinking switching point for the rejuvenation of industrial clusters. China has a single market with a population of at least 400 million, and its demand for high-quality life is the biggest engine for the development of industrial clusters. Under the double cycle at home and abroad, the phenomenon of double helix upgrading is remarkable. On the one hand, high-quality consumer goods are coming out. On the other hand, high-quality consumer goods need the support of a new supply chain to promote the synchronous upgrading of equipment materials and production methods. In recent years, many domestic brands are impressive. For example, the retail price of bubble beverage Yuanqi forest is nearly 6 yuan a bottle, which greatly exceeds the market overlord Coca Cola. It puts user experience in the first place, which is the "new quality thinking" advocated by the author. There are also Zhong Xue ice cream, bubble mat's blind box surprise and so on, which have brought a new trend of domestic products in Hula. The Hongguang miniev of Shangtong Wuling has successfully connected an electric car with a price of 350000 with the fashion of young people. It focuses on makaron color. In the end, it will make people feel that makaron is like the exclusive color of Shangtong Wuling family. Some executives in the factory simply wear macarone colored trousers. This unique design of listening to the voice of users also makes this small car, which was not valued in advance, become the single model electric vehicle with the largest sales volume in the world.

Behind this is the support of advanced manufacturing force system. It can be said that behind every new domestic product, there is a strong high-quality supply chain. Double helix upgrading, one is new domestic products, the other is high-quality supply chain. This is where industrial clusters need to make the most effort. Without excellent design, it is impossible to form a distinctive brand; Without excellent manufacturing capability, it is impossible to realize the designer's unique process. These are the key to the second spring of industrial clusters.

Conversely, without the protection of design creativity and high-quality supply chain to realize local manufacturing, an industrial cluster is dangerous. Facing the new competitive world and manufacturing pattern, pure business supremacy is closing the door to traditional industrial clusters.

Even declining industrial clusters have new opportunities. Akron, the tire capital mentioned earlier, has long become the capital of polymer materials. With the help of the local Akron University's top research in the chemical industry, Akron local enterprises have switched their knowledge of rubber tires to the polymer material industry. At present, its LCD panel glue is an essential raw material for domestic panel factories. Tire and semiconductor glue look different, but they have something in common on the basis of basic research. The roots of an industry are meaningful and need to be preserved. In May this year, Akron set up a monument to "tire workers" to remember the rise and fall of the city's industrial clusters. The prototype of the monument comes from the cover of a book "the wheel of Destiny: Akron's rubber story". This book, published in 1999, tells the history of the city's tire industry. History needs to be inherited, and history gives people strength. China's industrial clusters are at such a connecting node.

Wenling and Taizhou in Zhejiang Province have taken a surprising evolutionary route to the north. As a paradise of light industry, Zhejiang zone is an inevitable feature of industrial structure formed by the spontaneous development of industrial clusters. However, in order to solve the production of these light industrial daily necessities, another unexpected trend began to appear here in recent ten years, that is, the development of equipment industry. The bearing town of Xinchang gave birth to a local machine tool factory such as Zhejiang tuoman, which further expanded the bearing lathe to gear hobbing machine tools for gear processing. Gear machining is the most complex process in various machining links. Tuoman, on the other hand, has made great strides in the existing gear hobbing machine market of Mitsubishi Heavy Industries, and the domestic substitution trend is rapid, becoming the "king of gear hobbing machine". In Wenling area, many product clusters such as tool grinder have been formed. Zhejiang Beiping grinding machine is the leader in precision. Such a development from existing products to upstream supply chain is impressive. However, most industrial clusters are not so lucky. Among all villages and towns in China, Zhutan Town, which has the largest casting industry, has an automatic horizontal stripping molding line and automatic pouring machine, with an investment of more than 300 million yuan. The casting equipment is all foreign. Xindong in Japan and Yingda medium frequency electric furnace in the United States are regular customers here. In these places, the advanced level of industrial clusters often depends on the universal machine brand to endorse their own strength. In this situation, we must break through, let high-quality products go back, and force the chain to upgrade. A pencil seems simple, but the small pencil body needs to be painted 6 times to form, and it is required to dry quickly. This is the challenge to the process; At present, in the consideration of green environmental protection, water-based paint is replacing nitro paint. Behind this is the challenge to China's fine chemical industry. The upgrading of industrial clusters is a line where grasshoppers work together. This is the overall battle of the supply chain.

The digital transformation also brings new opportunities for industrial clusters. It will not only bring changes in machine operation efficiency, but also form a breakthrough in business model. Zhejiang Changling moved the home-based small workshop loom into the micro park for centralized order management and plant operation and maintenance after upgrading. The daily-use plastic industry cluster in Jieyang, Guangdong, and the central factory characterized by intelligent machines and order entry are attracting more small and micro businesses. Industrial Internet is good at integrating resources, and it is most appropriate to take industrial clusters as the object of centralized management. Through standardization, it makes the original backward management mode be forcibly upgraded. Digital transformation is a key step for industrial clusters to return to youth.

Notes: a group of nostalgia

Industrial clusters were originally a kind of rural economy. Give birth to me and raise me. Local people's livelihood cannot be abandoned. This is the main battlefield of people's livelihood economy. For the economic development of a place, just as the trees in the North play a role in consolidating and nurturing the soil and water. Without these trees, the land will soon degenerate into desert.

China's industrial clusters have reached a point where they must be upgraded. For the new generation, past success often becomes a kind of rearview mirror thinking, which only looks at problems from historical experience. Compared with the most easily felt structural change of labor cost, there are many deeper hidden reasons. For example, user changes under the changing times are often the least noticeable changes. Technological transformation is another gap, which is very different from the past. From machinery to mechatronics, it is relatively easy to understand the logic; But in the current software world, electromechanical software integration is a gap that cannot be crossed automatically. The learning of digital technology can only transition, not transition.

Only the change of employees' thinking can reactivate regional industrial clusters. With the manufacturing industry, we can retain the seeds of innovation and have roots locally. Industrial clusters are a group of nostalgia. When the industry declines, nostalgia will be diluted and slowly go with the wind.

This content comes from the network / Lin Xueping knowledge automation. This website only provides reprint. The views, positions and technologies of this article have nothing to do with this website. If there is infringement, please contact us to delete it!

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853