-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2304

Industrial software is hot and everything is boiling. However, the current definition of industrial software is too broad, which actually leads to the existence of many pseudo industrial software. I am used to dividing industrial software into industrial physics software and industrial management software. The latter, such as ERP and SCM, is not the focus. The former focuses on R & D tool software, such as design CAD, simulation CAE, electronic automation design software EDA or process simulation software, which are the real hard bones. Only by focusing the definition of industrial software on the real industrial core can we have better development. The current too broad definition is not conducive to solving the core problem. There is a software ranking list in China. Among the top 10 manufacturing industries, only Huawei, Haier, ZTE, Inspur and Hisense. This kind of software is basically embedded software. Without these software, the hardware will not work. But these software, in fact, have little to do with the neck software we are worried about. Nor is it my concern. We are still talking about developing industrial software that can serve independently, which is what China needs to break through most.

So, who is the crusader of industrial software? At present, the answer seems not so sure. Normally, suppliers are needed to break through. But the answer is also specious. The development of industrial software has never been a single player competition. It is more like a relay race. Without the research of basic mathematical physics, industrial software will lack foundation; Without the feedback of users, industrial software will never emerge. Many industrial software fails because there are no users. Not inferior to people, but inferior to people. Where there are no soldiers, there is no divine power.

So, how are industrial software forged? Historically, there are four main sources, namely, large industrial enterprises, universities and institutes, engineering and consulting companies, and entrepreneurial actions of entrepreneurs.

Figure 1 , the source of industrial software

The first source: industrial giants, get off halfway

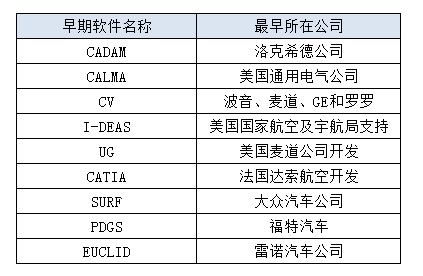

Industrial software such as CAD and CAE came from the interior of aviation and automobile industry. These two industries have become the most patient nanny of industrial software. Ge began to develop the earliest financial software in the 1950s and 1960s and became the first enterprise to develop its own software. Then, enterprise self-developed software has become a fashionable thing. Later, many industrial enterprises joined the ranks of self-developed software. In the field of CAD, this phenomenon is particularly obvious.

Table 1Origin of industrial software

Later, these software gradually formed the ability of commercialization, broke away from the embrace of industrial enterprises and became a company focusing on industrial software. Of course, there are also mergers and acquisitions and extinction.

However, the earliest development source of industrial software actually has special historical reasons. The earliest software commercialization degree is very low, because the demand is also very low, and no enterprise can survive independently by software. Therefore, enterprises must develop software by themselves, and the developers themselves are also large. The simulation software ANSYS originated from Westinghouse nuclear power and EASY5 originated from Boeing.

But the road then began to become deserted. The early development of software can also be completed quickly by a group of people. The current software code is often tens of millions of lines, and the relationship is very complex, which is difficult to be maintained by the internal team of the enterprise. If we can't achieve external sales at the same time, it will be a huge black hole.

Software development is a cost, and maintenance is another high cost. It can be said that the self-developed software of large enterprises can hatch the era window of general large-scale software, which has been permanently closed. It is unlikely that large industrial enterprises will insist on developing universal software by themselves. This is a blood path, because maintaining a system is too complex. In the 1990s, Ford Motor Company blocked the introduction of ADAMS software because of the personal likes and dislikes of department managers and insisted on developing a set of multi-body dynamics simulation software. Therefore, it suffered a lot and delayed for three or four years. Finally, it had to go back and embrace Adams.

There is a similar situation in China. The wind and thunder software of aviation hajif and wind tunnel base has been hard supported. Although they have played a certain role internally, they can not get through with civil software technology after all. They can only rely on the country's expensive rehydration to achieve continuous renewal.

Generally speaking, many enterprises will develop some software by themselves, but they are small software, which is difficult to shoulder the important task and realize technology spillover.

At present, funds are so abundant. Many large domestic industrial enterprises will reconsider this path. For embedded software, it is indisputable. Just as the number one arms dealer Loma needs to develop a lot of airborne software. However, if you want to develop foreign tool replacement software, it will be a hard bone to bite.

Now the software is highly complex, the cost of maintaining the system is high, and there are few users. Industrial software is a pyramid of knowledge. The more developers and users stack up, the better the software can be used. No matter how big an enterprise is, it can't afford such R & D expenses. Moreover, the output value of industrial software is pitifully small. A wise decision maker will not choose this path. The time window for large enterprises to develop large-scale industrial software that can be commercialized from scratch has been permanently closed. In the past, industrial software was relatively simple, which could be handled by lone heroes and star teams. But today is not what it used to be. Software complexity, let alone success, is highly uncertain, which is by no means affordable by the existing risk system of state-owned enterprises. Industrial software is probably the most unstable of all innovative products. Moreover, it is difficult for state-owned enterprises to solve the market characteristics of long investment cycle, large investment but small scale.

It is worth noting that large industrial enterprises can still make great achievements. With the help of its own users, it can effectively integrate the originally dispersed small software suppliers into a joint force. The trackers on the Volga River also need a coordinator who can shout. At present, Huawei's systematic layout of industrial software is just such an attempt. This approach is worthy of reference for large domestic industrial enterprises. Enterprise users are catalysts, but not pioneers themselves.

The second source: universities and institutes are the source

Industrial software has a close relationship with all universities and colleges. This is because industrial software needs a deep mathematical foundation, the ability to solve physical equations and the integration of computer technology. This also makes many industrial software become the holy flame flowing out of universities. At the beginning, almost all the funds of these universities came from government funded projects. Similar to NASA, NASA has more than 320 national laboratories, which are also the cradle of various process software. This explains the early relationship between government funds and industrial software.

At present, the British aveva software (which has been reverse acquired by Schneider Electric) in the process industry process simulation and pipeline software is the earliest project of the CAD center of the University of Cambridge, UK. At the beginning, it also started from mechanical CAD, but then gradually moved to the direction of factory building design, and created a completely different direction around the tortuous pipeline valves in the process industry.

Abacus (acquired by Dassault system in 2005), which is famous for nonlinear finite element calculation, is also from Cambridge University. The prosperity of rich basic disciplines such as mathematics and mechanics has brought many software companies to Britain. In the field of cam in the world of computer aided manufacturing, Britain is the leader. Darcom (acquired by Autodesk) and Edgecam (acquired by hexcom) are the leaders of the past.

AspenTech AspenTech, which is almost independent in the field of process simulation in the chemical industry, comes from the process industry of MIT. Ly DYNA, which is unique in the field of explosion, comes from Livermore, the National Laboratory of the United States. Berkeley played an important role in the pioneering work of CAE software and electronic design automation software EDA. At that time, their source code was generously presented everywhere. Many early CAE kindles in China are beneficiaries of these source codes.

But in China, this road has become a dead end, and many travelers have already taken a detour. Academic schools, whether CAD, CAE or chemical process simulation, have been comparable to overseas schools. There is no gap in the starting point of China's industrial software, at least go hand in hand.

In the current industrial software, the most difficult focus software is the electronic design automation software EDA, but this kind of software is prescient for Chinese academic circles. As early as 1978, the Academic Conference on "digital system design automation" was held in Guilin, which was the beginning of China's "EDA career". As a national large-scale computer academic activity, more than 140 representatives from 67 units attended the meeting. It is unprecedented. EDA at that time mainly focused on the field of PCB design. The computer department of Tsinghua University has made a good layout, and Beijing University of technology has also created EDA discipline earlier. The results of 18 papers in Guilin conference covered all aspects of EDA fields such as circuit analysis, simulation technology, printed board wiring and so on. There is no doubt that Chinese scholars and experts at that time almost kept pace with foreign countries in their grasp of technology and theoretical discussion. Although at that time, the hardware support environment was very poor. For example, the teachers of the Institute of Posts and telecommunications were almost unarmed. They just completed tens of thousands of data for logical synthesis with hand-held computers and manual calculations.

At that time, the reasons for the great development of EDA were surprisingly similar to today 30 years later. At that time, the organization responsible for the technical card neck was called the Paris Coordinating Committee (also known as "Batumi"), which embargoed EDA software against China. Without advanced tools, IC design is difficult to develop. The domestic demand for IC-CAD tools can be said to be thirsty for talents. So in July 1986, electronic design also ushered in the spring. At that time, the Ministry of electronic industry decided to establish three integrated circuit design centers in Beijing, Shanghai and Wuxi. This is the spring of domestic industrial software from 35 years. Do you feel deja vu?

Subsequently, China ushered in the sowing season of IC-CAD, which is an era of General Assembly war. Beijing integrated circuit design center gathered 120 people from 17 units to tackle key problems intensively in a factory.

At that time, the Ministry of electronic industry was really a skilled innovator. It skillfully connected the innovation chain. During the Eighth Five Year Plan period, the state transferred the task of IC-CAD industrialization to Huada design center, and completed the final version of panda system in 1995. The self-produced and controllable "panda system" in China was a blockbuster. At that time, 56 sets of panda systems were applied in 26 domestic IC design units and successfully entered the international market. At that time, mentor, one of the three EDA software giants, also integrated its own software with panda system.

China's EDA software has never stood so close to international software. But then things got caught off guard. Batumi was dissolved (instead of its continued embargo on China, it became an organization called "wa Association", and the new embargo was as old), and foreign EDA software was no longer embargoed. China's moat was quickly washed away and no one paid attention. Pandas are basically shelved. This is the price of not understanding the laws of industry.

History will not come back, but history will repeat.

The current backwardness of China's industrial software has never fallen on the starting line. On the contrary, at the starting point, Chinese software is also a respected peer. The Deputy Secretary of Commerce of the United States, who came to China to negotiate intellectual property issues, made a special trip to the design center of Huada and expressed appreciation for the "panda system" of China's independent intellectual property rights. As far as CAD is concerned, the early practitioners of Beihang school in geometric modeling have also received respectful academic exchanges from the French inventor of Bezier curve.

Beihang once founded the CAD software of honeysuckle, which was also one of the best diamonds in scientific research projects at that time. It also bravely went out of school and came to Guangdong. However, the academic software can not get the response of the industry. Scholars' efforts to challenge the market are like Don Quixote's challenge to the windmill. You can't say you don't have courage, you can only say it's inappropriate.

Gradually, the Academy slowly withdrew from the track. Only a few seedlings, such as Haier of Beihang (now digital Dafang), Suzhou Tongyuan of huakeda, and the mechanical analysis software of Dalian University of technology, can still hold their own territory.

Chinese academies, together with the United States, France and other industrial software powers, have obtained the seeds for the future. But later, the achievements of foreign colleges quickly changed their property rights and successfully handed over the banner to entrepreneurs who existed for adventure, so as to stabilize their feet. This is a thrilling jump for industrial software, which has never happened in China. This proves that there have been serious mistakes in China's industry university research handover. In other words, the soil of China's industry proves that this is not a suitable place for sowing industrial software. As one of the most special industrial products, the true face of industrial software has been little known.

The third source: engineering consulting, which is unique in the industry

Engineering companies are a unique new force in industrial software. They have contributed a lot of industrial software. Yokogawa electric, the leader of process automation in Japan, is undergoing intense digital transformation. The most obvious move is the frequent acquisition of industrial software. KBC software acquired by it in 2016 is from a British engineering consulting company, which is oriented to the global oil and gas, oil refining and chemical fields. Process simulation software is a necessary analysis tool in the process of technical consultation, and KBC company continues to strengthen its investment in this regard. He has also participated in many mergers and acquisitions. The biggest feature of this kind of software is full of understanding of process knowledge. Full of industry knowledge. Japan Yokogawa electric attaches great importance to this point. The next year, Yokogawa's knowledge experts officially went online to solve the remote efficiency monitoring of oil refining units.

Altair, which is a leading grid technology in preprocessing and has made great achievements in the field of simulation, was the first consultant to Ford.

Many people have not noticed that Canada's industrial software is actually very powerful. As the sixth largest power in the world, power software also has a leading position. For example, grounding simulation software CDEGS, electromagnetic transient simulation software PSCAD, large-scale power grid simulation software DSA tools, etc. Among them, the distribution network simulation software cyme and cyme are analysis tools for transmission and distribution and industrial power system, which are widely used in China. This is a very complex power industry software, including dozens of modules. The software was developed by a Canadian power engineering solution provider.

The world's top classification societies, such as Bureau Veritas(BV)Through ship audit software and ship digital asset management software digital aim to improve the core competitiveness. Waco, a global legal and compliance consulting company, has specialized in EHS (environment, health and safety) consulting and certification. Since 2016, it has acquired a series of software for safety barrier management and preventing initiative errors, thus turning Petrochemical risks into an advanced self-locking system.

EDS, which is well-known for it service outsourcing and consulting (the earliest company under general motors), took over UG, one of the three major high-end CAD companies from McDonnell Douglas in 1991, in order to better serve the automotive industry. However, in 2003, because of his eagerness to repay the debt, he had to spit UG to Bain Capital, and changed hands to Siemens in 2006, becoming the cornerstone of the latter's most important industrial software group. This should be the most painful sale of EDs. Bain changed hands in two years and easily made more than $2 billion. EDS once ate the famous Colney consulting company in the strategic field. It is an engineering service company and has always attached importance to the supporting value of industrial software.

This happens to be the most unfamiliar field in China. Chinese engineering companies have always paid little attention to tools and rarely contributed a loud software. In the international famous engineering consulting company, it is inconceivable that there is no industrial software. Petroleum Service Company Schlumberger acquired Canadian vmg process simulation company in 2018 to better provide a robust petroleum simulation platform for petrochemical companies. Think about it, if there is no unified methodology and unified tools, an engineering company is just a super contractor of manual work.

This is actually an important reason why China's industry is large but not strong. Only by relying on the close combination of software, methodology, knowledge and experience can we grab the fruit at the top of any industry value chain. The role of industrial software is the most prominent. Take EHS (environment, health and safety) governance, which has attracted more and more attention, as an example, large foreign companies are strengthening their investment in industrial software. From 2016 to 2018, there were an average of 10 M & A transactions in this market; By 2019, the number of M & A investments has risen sharply to 25. Even in 2020, when the epidemic is rampant, there are still 17 M & A investments. The most remarkable is the world-famous private CVC company, which invested $200 million in a certification consulting company such as ecovadis last year. Global engineering and consulting companies have been at war in the digital field, while domestic certification consulting companies are still living a good life in peace. Few people pay attention to China's backward gap in Engineering & consulting companies. In fact, it is even greater than the manufacturing industry itself.

In China, engineering consulting service companies have never provided the seeds of industrial software to the market. Because there is nothing here at all. There is no grain and no paper. This is not the most important thing. The most important thing is that even if we face the future, we are not alert.

The fourth source: engineer, entrepreneur, beast spirit

There are many code entrepreneurs in this industry. They came from coding at the beginning. Similar simulation software ANSYS was the earliest engineer from Westinghouse, the founder of Altair, the world's second-largest simulation company, and the earliest consultant. Bentley software, which dominates factory management and construction software, is an engineer from DuPont. Synopsys and cadence, the leaders of EDA, and American PTC company, which pioneered parametric CAD design, all have traces of founders.

In China, the four paths of industrial software development leave only a narrow entrance, that is, entrepreneurs. Whether it is Zhongwang, which has been listed, Suzhou HaoChen, which has an amazing download of CAD drawing software (the active amount of app is actually within the top 500), or Beijing dameisheng, which is a process industry asset management software challenging aveva and yingtu, there is the support of entrepreneurial beast spirit. Almost all the world of China's industrial software is supported by lone heroes. Behind every industrial software, there is an entrepreneur who has come a long way. Without their belief as support, the market of domestic industrial software is scorched earth.

From another perspective, China's industrial software is a history of personal blood and tears. In other words, it is basically supported by private enterprises. There may be struggles among universities, colleges, large enterprises and engineering companies, but they are almost wiped out on the road of commercialization.

Nuwa refined five colored stones to mend the sky. At present, these victims who persist in guerrilla warfare with several guns are ushering in a new five color stone. However, when the sky mending action is imminent and the joy is not on the top of the eyebrows, it is quite significant that a number of new faces with guns are flying from the horizon. Do not know where they come from, these people just heard the horn of capital.

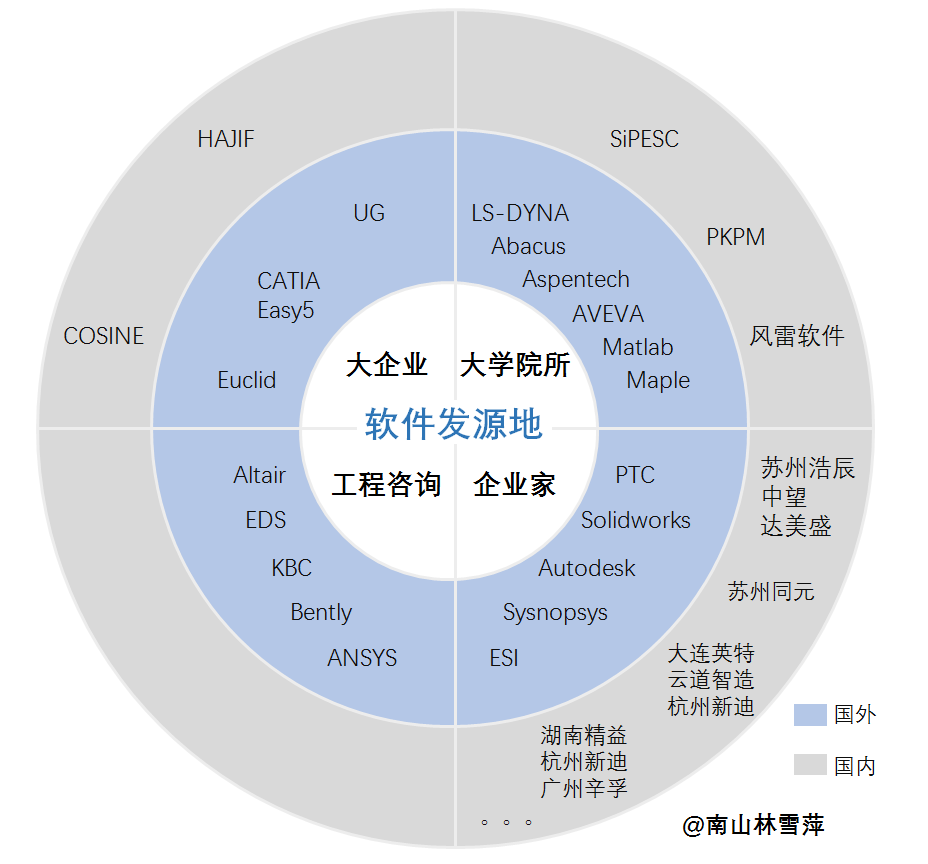

Fig. 2 Comparison of Chinese and foreign industrial software sources

Notes: who is the main attacker

From the development source of industrial software, it is a place with ventilation on all sides. In China, it is like the stone gate array left by Zhuge Liang for the famous generals of Soochow, life, death, shock and injury. One entrance and exit students, the rest are fierce. Only entrepreneurs managed to hold a position in Shengmen. The other three areas, especially the establishment faction, have made almost no achievements. This is a thought-provoking phenomenon. Perhaps there is no need to turn on the extinguished light again. Industrial software is a very special industrial product. Its unique characteristics of long cycle, high risk, large investment and low income are by no means controlled by the will of the chief executive, nor can the risk borne by the organic school carrying the short-term profit index.

The development of industrial software is like the layout of volleyball lineup. The main attacker, no doubt, should be an entrepreneur. The first setter is a University Institute. Starting from the foundation, we should do a good job in the transmission of basic research and the cultivation of talents; The setter is a large user enterprise, providing the best ball feeding position. Between the three, complete cooperation. What kind of war is industrial software? It is the common crystallization of tireless software suppliers, first-class feedback users and patient colleges. This is also a big test of China's industrialization spirit of division of labor and cooperation.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853