If you have excellent products and core technologies and take the lead in a segment industry, such an enterprise will become an invisible champion. But unfortunately, China is very short of invisible champions of small and medium-sized enterprises.

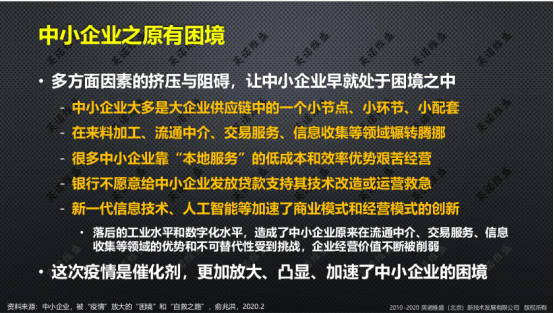

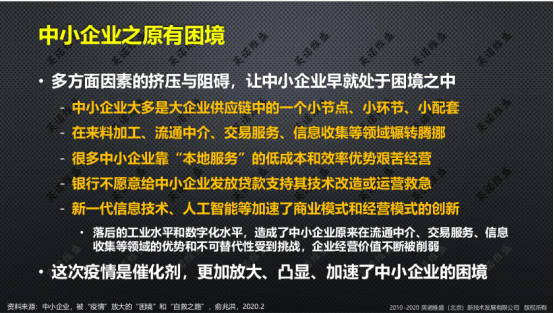

The plight of small and medium-sized enterprises

The plight of small and medium-sized enterprises has always existed, but the epidemic has exposed and exacerbated these problems.

The industrial level, digital level and survival mode of small and medium-sized enterprises are facing many challenges.

There are no excellent products and core technologies

If you have excellent products and core technologies and take the lead in a segment industry, such an enterprise will become an invisible champion. But unfortunately, China is very short of invisible champions of small and medium-sized enterprises.

Nonstandard management

Many enterprises lack standardized production process, management process, complete technical data, perfect reward and punishment measures, especially the digital level is not high.

No organizational guarantee

One or two people in the company master the core key technologies and develop products based on experience. There is a lack of correlation between departments and posts, the organization is relatively closed and rigid, and the response to the outside world is slow.

Generally speaking, the production mode and management mode of small and medium-sized enterprises are relatively primary, which is about the level in the middle of the second industrial revolution at the beginning of last century.

according to

Industry

four

Intergenerational

To divide, most enterprises are in industry

1.5 up and down

, and

Industry

4.0 there is still a "25000 mile long march" between intelligent manufacturing.

After the epidemic, many small and medium-sized enterprises are stretched and even difficult to support. Finally returned to work and production, but found that there was no order. So what should small and medium-sized enterprises do?

After the epidemic, how to "digital thinking" for small and medium-sized enterprises

Poor living environment, small and medium-sized enterprises are in danger. Live with digitization and take a step forward.

The concept of digital survival was first put forward by Negroponte in 1996. According to his interpretation,

Human beings live in a virtual digital living space

,

In this space

in

People are constantly applying digital technology

、

information technology

,

Engage in information dissemination

、

Exchange, study, work, etc

,

This is digital survival

。

This is not different from the digital survival we now understand.

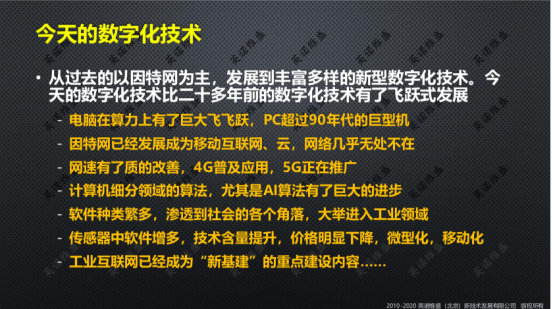

But today, more than 20 years later, under the technical conditions of the new industrial revolution, digital survival has different technical support.

The epidemic has changed our work and lifestyle

Has changed.

"Go to the cloud", now the course goes to the cloud, the conference goes to the cloud, and the popular "bring goods".

Not everyone can become a netizen,

"Band

goods

”Only

It's timely

, not really

It is forming the core competitiveness of small and medium-sized enterprises.

Small and medium-sized enterprises must find measures to increase enterprise value and enhance their core competitiveness.

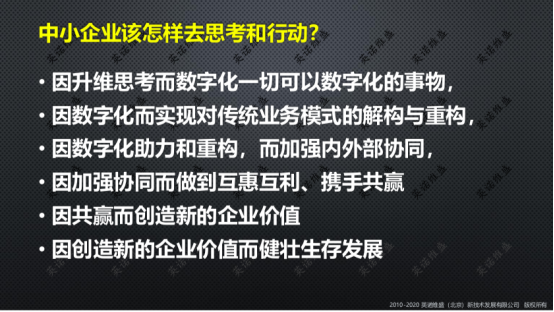

How to do the digital transformation of enterprises

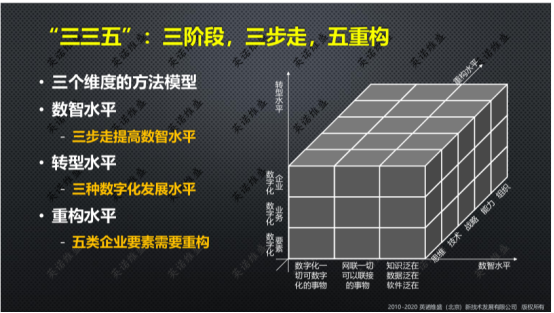

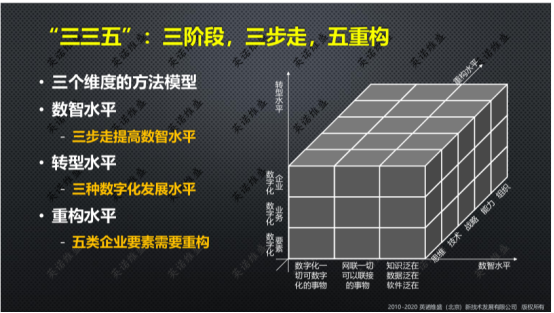

According to the views put forward by experts and scholars in the "towards intelligence series" of the Institute of intelligence, I put forward a "three three five" model for enterprise digital transformation.

The horizontal axis is the digital intelligence level

, how to go from digitization to intelligence.

vertical

Axis is

Transformation level

, enterprise transformation and upgrading, step by step.

longitudinal

Axis is

Reconstruction level

, enterprise elements are being digitally changed

Three steps of numerical intelligence on the horizontal axis:

Digitize all things that can be digitized, connect all things that can be connected online, and speed up

Knowledge flow forms knowledge ubiquitous, and continuously improves the digital intelligence level of the system itself.

It can also be understood according to the conventional saying that the key steps are digitization, networking and intelligence.

There are three levels of enterprise transformation on the vertical axis

Steps:

Element digitization, business digitization and enterprise digitization.

From the horizontal and vertical axes, digital transformation is not as complex as you think. We just need to start from the origin

go

45 degrees diagonally.

There are five levels of reconstruction on the vertical axis: all systems should be deconstructed and reorganized as far as possible, and reconstructed from thinking, technology, strategy, ability and organization.

Small and medium-sized enterprises are still

average

In industry

one

.5

about

level

,

need

stay

Make up lessons in all aspects

, we can do the first two steps well

It is a great leap for enterprises.

What is the first stage, the first step of thinking reconstruction?

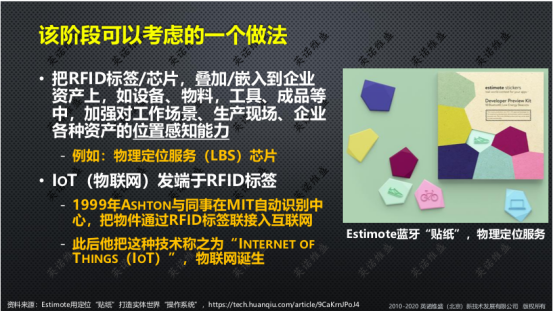

The first step is to digitize the elements, digitizing everything that can be digitized.

When considering enterprise elements, such as processes, documents, knowledge management, sales, internal meetings, material purchase, sales and inventory, see if any of these links can be digitized.

The first stage, the first step of technical reconstruction, based on the previous thinking, starts from the technical point of view to implement the digital technology. For example, establish an enterprise's own server (if the funds are not enough, consider the cloud platform provided by the government or cloud service providers), apply some primary software tools, and do some technology accumulation and knowledge management.

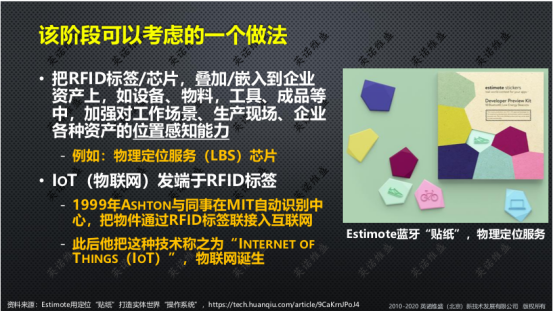

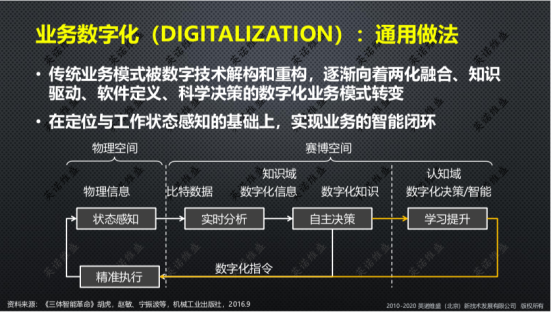

What is the second stage, the second step of thinking reconstruction?

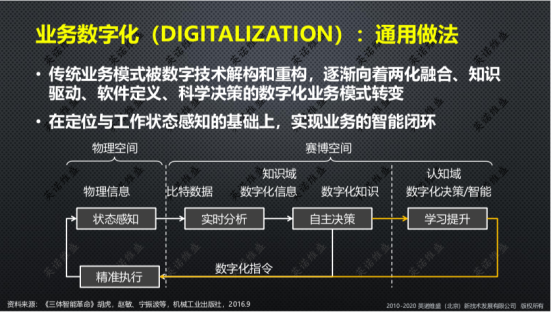

Based on the digitization of enterprise elements, this stage requires the digitization of enterprise business, and try to connect everything that can be connected. Try to let physical devices have data output, so that they can be networked and can perceive the on-site state of WIP.

Embed various sensors into

Equipment, materials, tools

In finished products

。

Someone asked if it would be expensive to embed so many sensors? If the price was 10 years ago or 20 years ago, it would be very expensive. Today, sensors are widely developed and popularized, and the price is only a fraction or even a tenth of that in the past. It has the conditions for large-scale sensors.

For example, a small industrial boiler enterprise in Tai'an once asked me, how do we do intelligent manufacturing for small boiler enterprises? I told him that small businesses can also start with digital business and digital products. It can be considered to add sensors to the key components of the boiler to monitor the operation status of the boiler. Boiler belongs to pressure vessel, and boiler explosion is a major accident. A variety of mechanical measurement sensors are added to the key components. According to the generated data, we can know the operation status of the boiler in time and take countermeasures according to the situation.

In business digitization

, you can use some software, such as

CRM

Software

Supply chain

Management software, enterprise management

ERP software, which is the gradual integration of the two.

I have repeatedly stressed that artificial intelligence is not necessary for intelligent manufacturing,

According to the three basic paradigms of intelligent manufacturing proposed by the Institute of engineering,

Artificial intelligence is an advanced stage

The third paradigm of

。

small and medium-sized enterprises

just

want

From the first paradigm

digitization

Just start with intelligent manufacturing

。

How to judge whether an artificial system has

Artificial intelligence? You can refer to the three body intelligence revolution

“20

Word proverb

”。

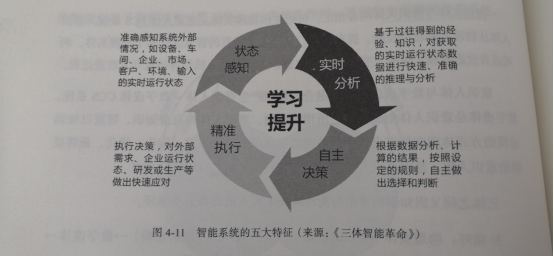

Twenty word proverb of intelligent system

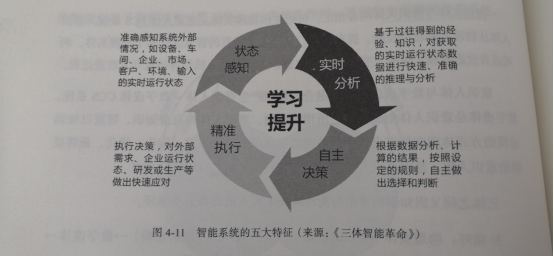

Five characteristics of intelligent system, also known as "twenty word proverb"“

State perception:

In the production site of physical space, cameras, mechanical sensors, thermocouples, voltage and current sensors, flow sensors, odor sensors, etc. are arranged to capture on-site data through state perception.

Real time analysis:

Convert physical information into binary bit data acceptable to the computer. It is a misunderstanding to think that informatization is computer processing information. Computers never process information, only binary data, and calculate and process data according to the mechanism model in the software. This stage is software real-time analysis.

Autonomous decision making:

According to the best data, inference rules and knowledge preset in the software, some decision-making mechanisms are formed. Automatically give the best decision in the current scene.

Precise execution

:The digital instructions formed according to the independent decision are sent to the controller of the equipment for accurate execution.

Learning improvement:

If you develop at an advanced stage, you have grown from small and medium-sized enterprises to large enterprises. You can add artificial intelligence algorithms on the basis of digitization. Machines are constantly learning. The more they learn, the more they understand the working process of the system, and the more accurate the decisions they make.

small and medium-sized enterprisesDigital transformation cases

In the Yangtze River Delta and Pearl River Delta

have

six thousand

10000 garment workers, about

There are 450000 small and medium-sized garment enterprises, and many garment factories have hundreds or thousands of people. Of course, there are also small workshops with dozens of people. This is a typical labor-intensive enterprise, with only sewing machines, ironing, dust removal and cutting

Infrastructure, far from what we thought

"Tall" is too far away. Such enterprises are doing intelligent manufacturing with little success.

State perception

、

real-time analysis

、

Autonomous decision making

、

Precise execution

,

From digital to intelligent

Intelligent system to form a closed loop.

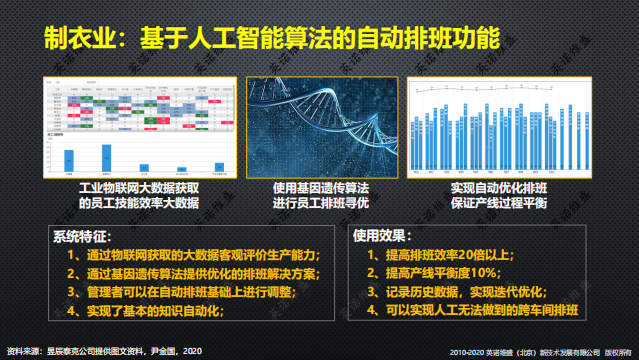

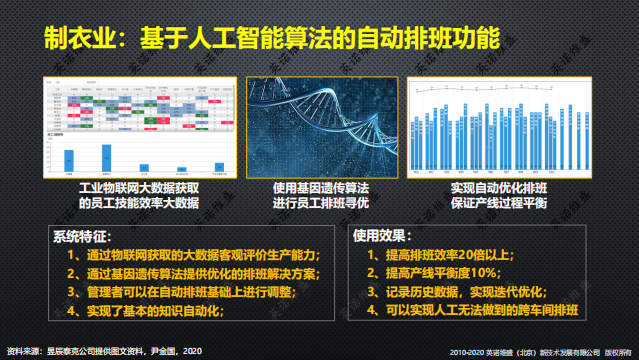

The sound frequency and duration of a worker stepping on the sewing machine can characterize a person's work skills. For example, an excellent employee can aim a long stitch at the front and rear flaps of clothes and step on the sewing machine successfully

, total

1-2 seconds. If his apprentice is not familiar with the technology, the sound frequency should be lower, the time should be longer, and even there is a pause in the middle operation. The station attitude sensor is made into a small box and nailed under the sewing machine panel. Each workshop uses a large box to collect signals from 200 sewing machines. The large box passes through the position attitude sensor

"State awareness"

“

Then we got the vibration data of the sewing machine panel.

The background server uses industrial software to process all collected data

analysis

, know whether everyone is doing well or not, and can use artificial intelligence algorithm to automatically arrange shifts according to the on-site work progress.

This is it.

Autonomous decision making

。

Finally, the work tasks will be scheduled in real time according to the work scenarioPrecise implementationTo people.

Realize optimized dynamic scheduling,Shift scheduling efficiency has been improvedMore than 20 times,The balance rate of production line is improved10%,The overall benefits have been improved30%。

One family systemOptimization of garment enterprises to30% profit increase, you can imagine how good this effect is.