-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2701

Quality is the closest echo to the times

The rise of domestic brands in recent years has become a remarkable phenomenon. Whether it is a high-priced vitality forest bubble beverage, a blind box surprise bubble mat, or a second-hand tourman gear hobbing machine with high insurance value, it has set off a surprise scene in their respective fields. Their distinctive concept of quality makes people rethink the proposition of "century old soup" of quality. The quality is a Mona Lisa painting, which is praised by everyone, but their tastes are different. The definition of quality is also changing.

Version 6.0 of Julan Quality Manual published in 2014 concisely summarizes quality into two main points: quality is defined by customer satisfaction and loyalty, and characteristics and defect free are the two main determinants of satisfaction. Product characteristics will affect sales revenue; If there is no defect, it will affect the cost. This simplicity has brought a deep impression. It is described in a language that the operator likes - money. This is exactly what Crosby mentioned in his book quality is free, "managers only know one language, that is money".

However, with the development of productivity and the full entry of social economy into the era of strong buyers, these two dimensions begin to look a little pale. Because of the user's psychological experience, it began to become more and more important. In the rapidly developing industrial era, there is no time to wait for a new definition of quality, and many phenomenal products have begun to rush out. The experience quality strengthened by psychological senses is forming a third dimension beyond the two dimensions of quality defined in Julan manual, so that it should be an independent portal.

Reinvent the wheel

The phenomenon of new domestic goods is to find a blue ocean in the seemingly red ocean market. It seems that they have redefined one of the most common products. "Re" is to strengthen the "experience factor" (also the quality in the hearts of users), so that the products used to be refreshed, refreshing and pleasant to use. This is a typical phenomenon of new domestic goods.

Yuanqi forest adopts a brand-new quality strategy, and the cost is trampled under the foot. Initially, Yuanqi forest also made strategic choices according to the traditional positioning strategy. At that time, Coca Cola was targeted at 3.5 yuan. Yuanqi forest sold for 4 yuan, and the cost was about 0.5 yuan, while the channels and terminals were 30% respectively. It sounds like an impeccable positioning strategy, but employees don't want to drink the products made at this cost. Finally, products worth 5 million yuan have been produced and all have been destroyed.

The positioning theory is good, but the product is not effective. The fundamental reason behind is the lack of "user experience thinking". A lot of traditional frameworks such as cost and delivery limit the idea of innovation. Both strategic considerations and quality thinking are the theoretical products of the 1980s. It is difficult to win the hearts of new consumers of generation Z with such outdated earth guns and old weapons.

So Yuanqi forest decided to start with experience. The person in charge of product development, regardless of any cost, uses good materials as much as possible to make a drink he likes. Driven by this super experience, Yuanqi forest took the lead in adopting sweeteners that are very close to sugar taste in the industry. It costs 50 times more than traditional aspartame, and 99% of the sugar in the juice bubbles comes from the juice. The experience is put in the leading position, and the cost is put behind. Before all products are launched, the product personnel and sales personnel do not know how much the product cost is. Until two or three months after the launch, the financial personnel tell them the cost and gross profit.

This strategy based on experience quality makes the bubble beverage of Yuanqi forest quickly become a phenomenon product.

Dr. Bei, another start-up, dissected the traditional toothbrush. China's toothbrush has always been based on the concept of whitening, and hard brush wire has become a deep-rooted standard. In Hangzhou market town, Yangzhou, the hometown of toothbrush, which accounts for 80% of the domestic production share, the competition in toothbrush basically stays in the aspects of shape, color and cost. The toothbrush recruits of this family, who do not have a deep access, start with the concept of nursing health and grasp the key of modern oral care: gingival cleaning. It redefines the experience of a toothbrush. The brush wire should be hard and soft, hard enough to go deep into the gum without falling down, and soft enough to rub hard and comfortable. The toothbrush, also based on aesthetic design, focuses on the injection sealing that no one pays attention to: in the past, each toothbrush left this navel like hard mark, which is the final closure of plastic extrusion. The implantation method of toothbrush wire has also been improved, so that the toothbrush wire can stand better. Starting with wire brushing and toothbrush handle, both are based on experience quality and put the real feeling of customers when brushing their teeth on the top priority of an enterprise.

Who would have such a mind? Experience quality has become a strategy of core competitiveness. The founder of this toothbrush company is a designer from Lenovo. The product designer of Yuanqi forest comes from the game industry. It can be said that they bring a new experience to the most common products. Experience surprise and return surprise. Designers who have opened their brains and consumers who are overjoyed have connected the two by experience and completed a beautiful encounter.

Why did Japanese household appliances and mobile phones famous for their high quality decline? In a sense, they mistakenly remain in the era of traditional quality. Traditionally, the quality requirements are consistent and good performance, so that Japanese manufacturers keep improving, forming a deep-rooted tradition of "excess quality", and some refinement has even reached the inner volume level.

Mobile phones are FMCG products, but they have a life cycle of one to two years. When the performance of mobile phone parts is still stable, users who like the new and hate the old have begun to replace new mobile phones. Product life, can no longer wait for the end of life. China's mobile phone manufacturing has grasped the psychology of user experience quality and accelerated the iterative development of products. According to the Nikkei news report, the iteration speed of Xiaomi 5g mobile phone is too fast. In April 2021, the cost has been reduced by 40% compared with half a year ago. This makes the Japanese feel incredible. After entering the era of Internet TV, TV focuses more on content and updating. This makes Japanese household appliances that stick to traditional quality such as specifications and sizes helpless. Japanese TV has never entered the Internet track. These two categories of products are basically defeated by South Korea and China. The change of users' psychology has formed a different quality impact. This is a rather uncomfortable place made in Japan.

In fact, made in Japan should have learned this lesson earlier. After the 1980s, memory was basically dominated by Japan, accounting for more than 80% of the world. However, Japanese manufacturing was so committed to reliability and long-term quality, and the continuous improvement of technology brought a great burden on the product cost, completely ignoring the trend of rapid development of computers according to Moore's law at that time. The life of a computer is only 2-3 years. What is the significance of a memory chip that ensures the quality of ten years? The pursuit of quality in technical indicators naturally leads to high costs, which has become a kind of damage to Japanese semiconductor manufacturing. Six chip giants have gradually withdrawn from this market in the struggle of merger and joint venture. Only Toshiba's memory chip assets survived after several moves, but the equity has been changed and the name has been changed to armor man.

The rise of user planet

People have increasingly noticed that the trend of social psychology and demography that seems too macro will affect the strategic trend of large and small enterprises. The change of population structure is not easy to be perceived, but it is one of the factors that deeply affect the manufacturing industry.

Young people born after 1995 are generally called generation Z. Generation Z consumers are becoming the main force of consumption. In addition to houses, luxury cars and other commodities, other types of consumer goods are attracting their eyes. The biggest feature of this era is the fragmentation of information. Generation Z experienced the Internet as a child (2001) and began to contact the mobile Internet at the age of 10. It is a group of cloud native residents. Their relationship with social media has been a natural relationship between fish and water. These consumers are more concerned about opinion leaders and community speakers.

Those who have experienced material poverty and entered a new era are often more infatuated with big brands. Now, generation Z consumers are reasonable and have no respect for the traditional old brands and big brands for decades.

As the understanding of the world has been fragmented, the market has been infinitely divided. And every crack in the fragment can find enough people and opinion leaders. This is an era of micro opinion leaders. In this small crack space, there is enough sunlight to moisten small species. These small markets with unified views are enough to make new manufacturers stand out and earn the first pot of gold.

This is the biggest opportunity made in China.

Tiktok was the first to know the tremble. It was only in the second day of 2019 that the children did the first tiktok in the way of shaking. Then when I noticed it, it was unstoppable. At the beginning, the hymn of the new product was like a small sound passing through the crack. It turned out to be a grand symphony hall. Generation Z consumers are such a choir.

There are many other products, such as Zhong Xue ice cream, ice and snow honey city milk tea, bubble mat blind box, etc., which are known with children. Children have been infatuated with them for a long time before parents realize it. It seems that the likes and dislikes of junior middle school students are full of business opportunities. If we reflect on the methods of creating wealth in different times, it is also worth thinking about. Huaxi Village, Wahaha and other older generation entrepreneurs read business opportunities by watching news broadcasts and people's daily. They are following the policy market. Now, there are also huge business opportunities to understand the minds of consumers. It can be said that the predecessors get rich and watch the news broadcast, and now the young people of generation Z / junior middle school and senior high school get rich.

From another point of view, no matter what kind of users, they also began to become picky. There are both positive ones, such as the pursuit of better sensory enjoyment, or the ability to carry out early warning analysis of machine faults; There are also negative aspects, such as power anxiety disorder (I will care about the power grid of the mobile phone, or the endurance anxiety disorder of electric vehicle drivers). After placing an order online, I will start to care about the location of the package, and it is difficult to tolerate the delay. These factors almost didn't exist only ten years ago.

In the network age, the time dimension is compressed, and people begin to express their psychology with a shorter time scale. Both positive and negative experiences mean that the connotation of quality becomes more comprehensive, more sensitive to time and more characteristic of social psychology. Digital technology makes the factors that can not be expressed begin to be explicit.

These unusual phenomena related to experience quality make manufacturers feel that quality needs a better coat from the perspective of enterprise management.

Quality tetrahedron: more, faster, better and better

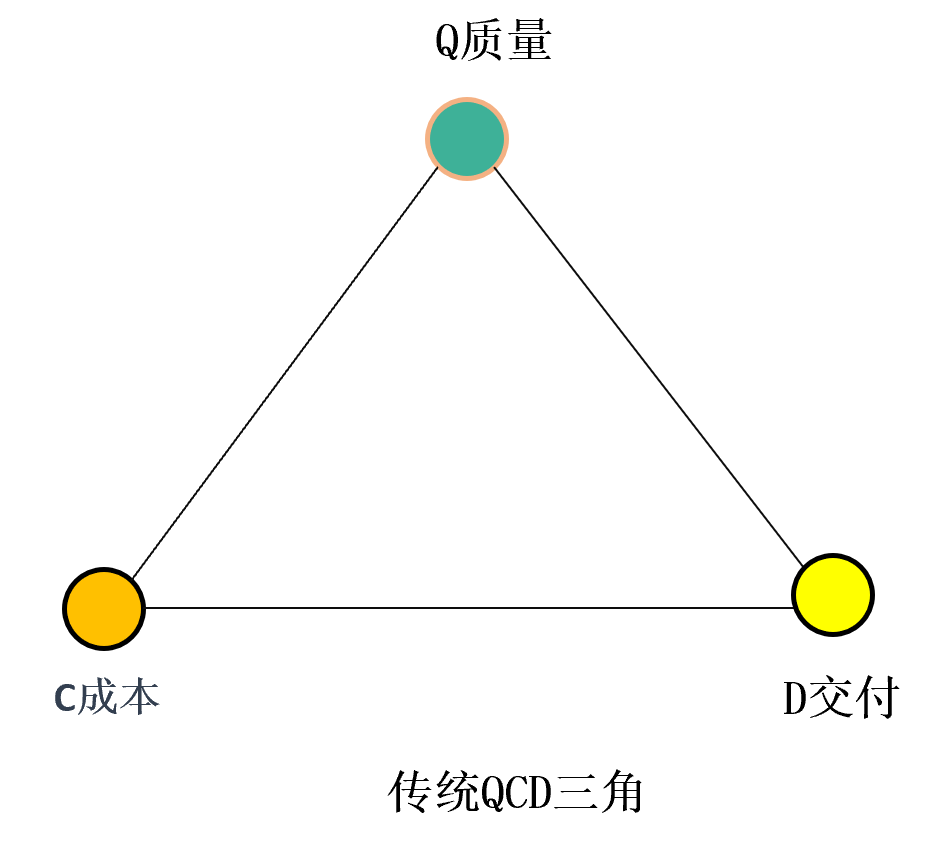

General enterprises operate in the Golden Triangle - Q, C and D, corresponding to quality, cost and delivery respectively. This is a triangle with very stable business operation. The three restrict each other, so that enterprises have to compromise repeatedly in fear of gain and loss.

Figure 1 traditional mass triangle

This is the basic constraint faced by any manufacturing enterprise and is also regarded as the golden rule and iron law. However, is the sum of all triangles 180 degrees? Not necessarily, spherical triangle, that's not the case. Gauss law proves that the inner sum of spherical triangle is greater than 180 degrees. These categories of non Euclidean geometry often show different characteristics. The sum of internal angles of triangles on concave surfaces is less than 180 & deg;.

Enterprise management may also encounter such thinking patterns being broken. The quality in the traditional golden triangle is actually the characteristic quality of the plane, and the experience quality is much more complex. The golden triangle can no longer maintain a plane.

The quality of a product should be considered in the QCD triangle. The tighter the delivery date, the quality may be affected; If the cost exceeds a certain limit, it can not be accepted. However, if the product is put into the market and can make money for users, the cost of the product will have a huge ambiguity.

Tesla is a company that goes hand in hand in energy and electric vehicles at the same time. Its energy storage device and electric vehicle are linkage design after systematic consideration. Its power system is designed to rely on self-sufficient clean energy instead of traditional power grid. Tesla's energy storage device can conduct high-frequency grid transactions. Transmission to the power grid during peak power consumption; When the power consumption is low, it will charge itself. Through high-frequency power trading, you can make money for users. This peculiar design of "making money from products" will impact the original cost concept in the traditional triangle of QCD.

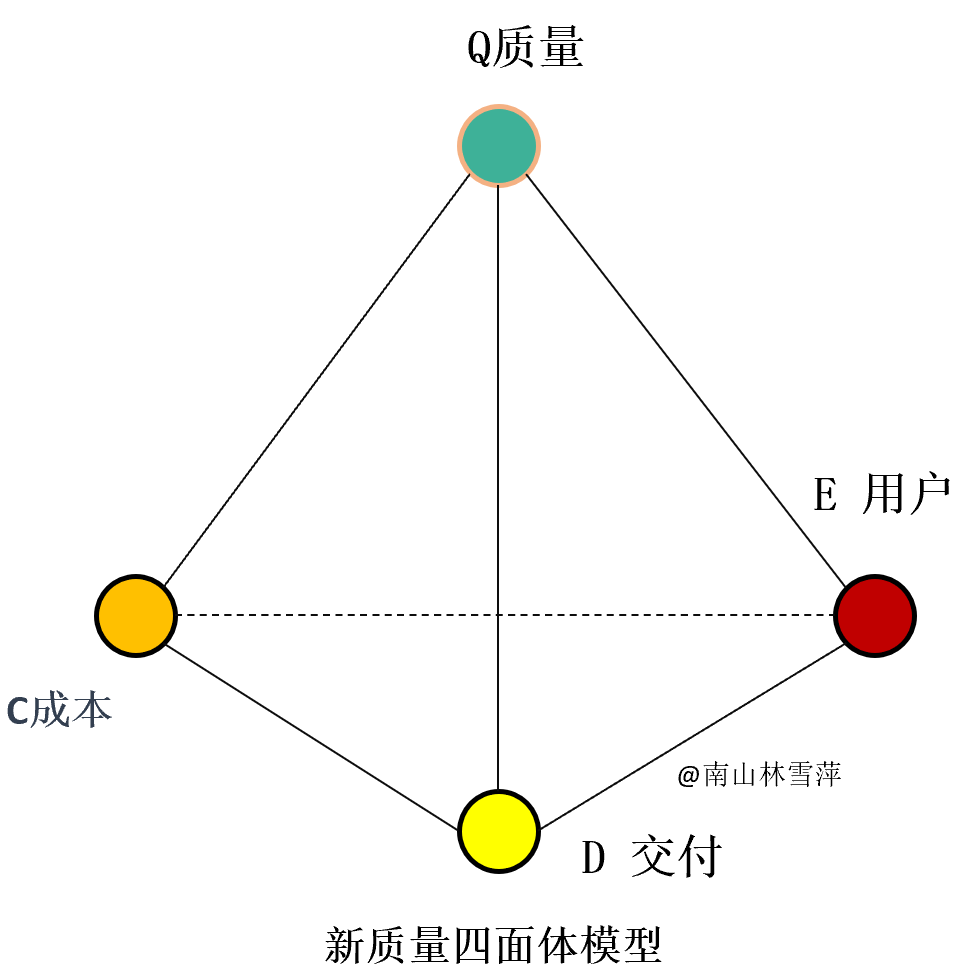

Considering that the experience quality in the quality dimension is rising from a negligible weight to a key position that may have a significant impact on the enterprise strategy, the position of users in the enterprise has to be repositioned. The operation of an enterprise can no longer put users outside the boundary of the factory, just as a service object. It seems that the user is no longer an external boundary condition, but has become a hard constraint on the operation of an enterprise. Users in the new era are no longer insiders wandering outside the door, but break into the door of the enterprise and become regular visitors who can't be sent away. Enterprises and users can sit down and define products and quality.

Figure 2 new mass tetrahedron model

So far, the new quality can finally have a preliminary definition of its own. It is the desire or degree to pay for it in order to meet the joy of user experience. Its biggest inspiration to enterprises is that Q stands up from the traditional quality triangle and moves from plane to three-dimensional. In the traditional QCD triangle, q is the same dimension as C and D. Because the subtext of traditional quality is to meet the requirements, meet the standards and the engineering design of products. This understanding has been left behind the times, because only meeting the standards is not enough, ignoring the original driving force of users, which is undoubtedly self pulling and self singing. Quality based on experience quality is no longer a variable of the same dimension, but is improving its position. At the bottom, a new variable E (end user) is added to form a tripartite confrontation with C and D and support the sharp knife effect of quality (high dimension). This new variable is the user.

QCD has moved from side-by-side on an equal footing to a compendium led by Q. The new quality thinking is to highlight quality. Let quality become the sharp knife strategy of the enterprise and realize strategic leadership. The new quality tetrahedron can be seen as a response to the rise of users.

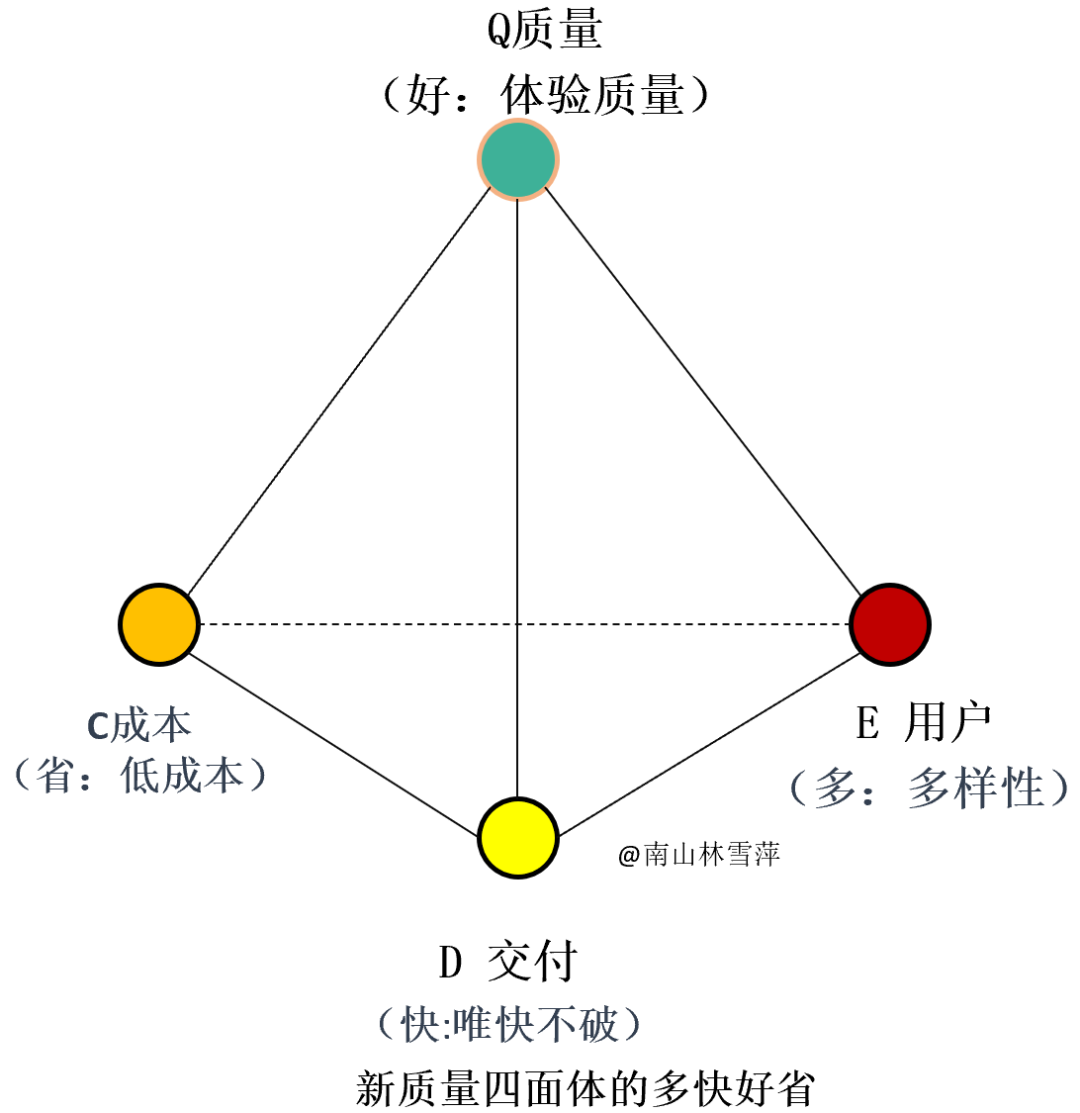

Figure 3 connotation of new mass tetrahedron model

Quality is the abstraction of products. It needs to answer three basic questions: who to serve, how to deliver and how much to cost. A product needs specific customer groups, delivery process (including production, service, etc.) and cost, which constitute the product portrait, and the quality based on experience quality is an effective bridge between enterprises and users. The fragmented quality God, once torn, is becoming the product soul again with the addition of user fulcrum.

The quality tetrahedron embodies the business philosophy of "more, faster, better and more economical" and "good" first. The first is "good", which requires the quality of experience to command the hearts of the people; "Fast" corresponds to a set of rapid delivery system, which can effectively meet user expectations and reduce psychological anxiety.

For "province", a mature cost oriented design and well functioning manufacturing system are needed. Low cost is a high-tech virtue. We should not only do it right at one time as Crosby said, but also achieve one step in place from the perspective of operation (such as rapid mold change and big data analysis). Low cost is an ability to surpass the cost of peers, which is the embodiment of innovation. Reduce the cost through scientific methods and eliminate the waste invisible to the naked eye. The minimalism of industrial design is to reduce the waste that does not add value.

And users reflect the difference of "many". Different products to cater to different groups. Listen to users' diverse ideas and identify the true meaning from the noise, so as to identify countless potential needs.

The quality tetrahedron reinterprets the enterprise management concept of "more, faster, better and more economical". The watershed between new and old quality is how to treat customer needs and customer experience. The focus of quality tetrahedron is to take the customer as the basic variable and put it in the same position as delivery and cost. As the leader, Q includes the most important aspects of traditional quality such as original consistency and performance. On this basis, it is the experience quality characteristics that make Q stand out.

2B should also read 2C's heart

So is experience quality just a 2C enterprise for consumers? It's not. All upstream suppliers should have a heart of "experiencing downstream" in order to really do a good job in product quality.

A large number of enterprises that do not directly face end customers (such as industrial raw material production, parts and other enterprises) should also keep the thinking of end users 2C at all times, so as to realize the sugar gourd effect of manufacturing consistency across distances. Raw materials should also consider the end demand, because the product will always be used by the end user. If the final feedback is not good, the whole upstream and downstream supply chain will be involved.

A factory B received an order from European end customer C and proposed the need for high-strength sewing thread capable of withstanding 20000 revolutions per minute. Factory B found upstream industrial raw material manufacturer a. With strong technical strength, company a soon learned about Japan's Toray technical standard, which was the first in the industry at that time, and found the material object (the product raw material produced by Toray in Malaysia, commonly known as horse material) for testing. Company a began to optimize the process after the standard horse material, and soon realized that all performance indexes of the product reached or exceeded the horse material. Everything seems perfect. The product is confidently sent to downstream manufacturer B for processing.

However, B's processing of this batch of horse materials can not meet the sewing thread requirements of European end customer C in any case. Depressed enterprise B fed back to enterprise a and asked for improvement. However, enterprise a believes that all technical indicators exceed the Ma material of the world's best Toray company. Where is there room for improvement? B processing enterprise believes that the Toray standard is not important. Even if it meets the United Nations standard, it will not work as long as the end users are not satisfied.

Both sides complained to each other, but the export order time was not waiting. Therefore, enterprise a and enterprise B began to organize technicians to analyze the product requirements of C. The two joint R & D personnel found that the high strength of sewing thread is not directly determined by the strength of raw materials. Its strength is determined by other indexes, such as crimping performance and holding force. Although the product indexes produced by company a are better than Toray, it does not mean that the comprehensive performance is also qualified. Toray's horse material (raw material) has actually passed a series of index combinations, and finally achieved special comprehensive properties. It relies on appropriate curl and improves the holding force between fibers to achieve the strength of sewing thread. This comprehensive performance has been ignored by enterprise a, which is more important for the processing of company B and the use of company C.

Through the routine of upstream and downstream engineers of a and B, it is agreed that the comprehensive performance of sewing thread can be realized by improving the process, and the strength requirements of raw fiber can be reduced, which is conducive to saving cost. Looking back at the early stage of new product development, in order to meet and exceed Dongli Ma material, enterprise a even sacrificed output and cost to improve strength. The engineer realized that his goal in the early stage was to "eat seafood for rabbits". He wasted resources and didn't please his efforts.

The end user proposed that the high-speed sewing thread must have high strength characteristics. After this demand point was passed, it was decomposed into several fixed indicators, but did not understand the comprehensive indicators of the products of competing manufacturers, which brought about a "pseudo demand" for performance cognition. If we can deeply study customer needs, we will find that the higher the index, the better. Some indicators that are not very important can even be reduced, so as to save costs. This means that we should not stick to the technical specifications, but re-examine them and re map them into new technical indicators according to the needs.

If we study the requirements of the C-end earlier and interpret them into more reasonable technical requirements, then a and B will jointly develop one day earlier to deepen their understanding of product processability, which will get twice the result with half the effort. In product development and design, we should always remember t o C, and then to B and a work together with B to meet C, so as to quickly develop high-end products required by the market.

Most Chinese enterprises are part of the industrial chain and will face the processing and assembly of downstream B enterprises. In case of delivery of B, we should not only consider the specifications and technical requirements. As industrial raw materials often need secondary processing, priority should be given to customers' processability, usability and assembly, which is also the "customer experience" of the next user. In this way, there may be a completely different understanding of quality and cost. 2B enterprises also have 2C characteristics in essence, and must also consider the customer experience, which is only slightly different from the customer perception experience of consumer goods.

The new quality thinking is reflected in the change of thinking. Regardless of 2B and 2c, the upstream and downstream must be connected in series to form the sugar gourd effect. In this sense, experience quality is an inverted sentence. Business operators may as well mention the most remote users to the front for quantity.

Quality classics are also waiting for a breakthrough

As far as the technology involved in quality engineering itself is concerned, it is also stretched. At present, the penetration of quality awareness in China is still an era of slash and burn cultivation, although agriculture has entered a new era of intelligent agricultural machinery and UAV sowing. The traditional 5S and SPC theories still haven't made a big breakthrough. It can be said that the technical tools laid by Shewhart nearly 100 years ago have not evolved, and have not formed a good integration with the complexity of the current manufacturing system and digital technology. In the past, there was an empirical formula to look at the change trend of seven consecutive points in quality inspection, which was the product of the sampling inspection era. Now, due to the popularization of automation technology and computer technology, full inspection can be achieved, and the situation has changed greatly with the original era of sampling statistics. This empirical formula needs to be changed urgently. If the so-called 7-point continuous change trend is followed, how many nonconforming products may have flowed to the market. This means that SPC sampling theory and algorithm knowledge have not kept pace with the times.

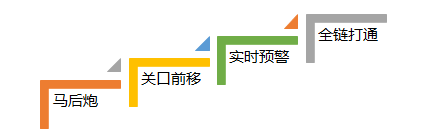

For a long time, quality inspection is the last gateway for enterprises to product quality, and it is also a helpless choice. This way of intervening in the quality after the event is undoubtedly waiting for the rabbit, or simply post-mortem. Although the detection methods are becoming more and more sophisticated, the way of being beaten passively also makes the quality management personnel worried. Therefore, the saying that "quality does not depend on detection" is heard all the time.

In the 1970s, at the peak of Japan's economy, Mr. Xuanyi Taguchi, a quality master, proposed three designs, with the intention of moving the jurisdiction of quality from the manufacturing front end to the design front end. The pass moved forward, and the hindsight became Zhuge Lang's clever plan in advance, which made great contributions to the introduction of Japanese products to the world.

At the beginning of this century, Americans put forward six sigma oriented design on this basis, with more emphasis on listening to the voice of customers. System design, axiomatic design, TRIZ and other methods have also been widely spread and applied. However, these advanced tools and methods 30 years ago have not been well adapted to the blowout data ship in recent years.

With the development of Internet of things and digital technology, a large number of on-site data can be detected and decided in real time. The user's feedback information will also be captured in real time. For the most remote users, their digital portraits become accurate; Insignificant abnormalities of machines on the factory site will be captured in real time. Moreover, the quality data of upstream suppliers can also be shared to realize linkage tracking and open up the whole chain. Time stamps that affect quality are everywhere. Quality and technology are undergoing earth shaking changes.

Fig. 4 time memory of quality gate

The impact of blockchain on quality will also be far-reaching. The current quality supervision is still a centralized way. In case of quality problems, the quality supervision bureau is the highest ruling structure. However, in the whole supply chain, quality is easy to quarrel with each other. As for the quality tracking of blockchain, the information cannot be changed and the traceability is clear, the quality tracking will become transparent.

Even if we go back to the most common scenario of low-end factories, many older operators with low educational level in the factory only need to operate simple basic operations such as code scanning and submission, rather than piecework employees and complete records by themselves, which will make the quality data flow in a coherent state, so as to greatly improve the quality level.

Of course, the simple quality management information software QMS has improved the level of informatization, but it is not enough to talk about the transformation of quality thinking. When introducing quality management information software, many enterprises still only express the data in the process. It can be said that small rivers are introduced into a reservoir, but the source of quality has not been planned at the top. This requires a brand-new change in the quality thinking of the enterprise. These small diversion canal projects can really become a major mission project like Dujiangyan and the flower of the operation of irrigation enterprises.

New quality is not born out of nowhere, but on the basis of including traditional quality, it emphasizes the application of new thinking and new technology. In short, new quality has three legs: the product features and defect free legs of Julan manual, plus one leg of experience quality. In fact, even if the experience quality is not obvious on some occasions, the other two legs can still be nailed and reinforced by the new enabling technology.

The manufacturing industry needs to keep up with the concept of new quality, keep up with the integration of new technologies, and re form a set of framework and way to look at quality.

Double circulation with double helix

The rise of Dr. Bei's toothbrush is a victory of experience quality. It has brought great surprises to Chinese consumers. However, it has also brought a troublesome problem to manufacturing. China's supply chain can neither produce such brush wire (finally go to Japan's Toray), nor provide a machine to implant the brush wire into the toothbrush (finally need to use German equipment), nor even find a factory. Finally, we found a domestic OEM of Europe's top brands to produce such toothbrushes.

The same embarrassment comes from shutI, a high-end trolley case brand in China. In contrast to the tradition that domestic travel trolley cases are only made at the low end, shutila aims at benchmarking directly with international brands such as rimova and xinxiuli. After ten years of rolling, shutila has successfully gained a foothold in the challenge arena. Its stores are only next to xinxiuli and never discount. Even Weiya's strong live delivery channel can't let Shu Ti change her new ideas. Why discount for high-quality experience? However, what really makes shutI bend down is neither the design on the left side of the smile curve nor the brand on the right side, but the manufacturing link. Neither the bag and suitcase capital of Baigou, Hebei Province, whose shipment volume accounts for 1 / 3 of the country, nor the bag and suitcase base in Shiling Town, Guangdong Province, can provide decent wheels, nor ensure the flexibility and rigidity of box raw materials, and even pull rods can not be produced. Finally, this product can only find the only factory in Taiwan, China.

This phenomenon is thought-provoking. When high-quality consumer goods have been upgraded, whether the supply chain is ready to enter synchronously. Dr. Bei and shutila are beginning to promote the pull of domestic supply chain and activate the upgrading consciousness of front-end supply. In the automotive sector, more good news came. In recent years, the development of electric vehicles has driven the rapid progress of China's supply chain. Because of the roar of the engine itself, the internal combustion engine fuel car masks the meshing noise of the large and small gearbox of the car. But the electric car became quiet because there was no internal combustion engine. The long-standing sound of automobile gears suddenly became intolerable. Gear suppliers began to put forward the same high requirements for upstream gear processing equipment. In the traditional automobile manufacturing system, it is difficult to have domestic equipment. The rise of China's new power of electric vehicles has also opened a door to domestic machine tools. Tuoman, a gear hobbing machine manufacturer from Xinchang, Zhejiang Province, has entered this market strongly, which has played a great substitute effect for the market of Mitsubishi Heavy Industries in Japan. Such substitution is not accidental, but also a strategic victory of experience quality. The company takes "the user's chief craftsman" as the product design concept to deeply experience the user's experience. Due to the excellent experience quality and carefully improved technology, the second-hand value of this machine tool is also very high. This is the return to the quality concept.

Internet and it experts who enter the fields of traditional household appliances, beverages and food will bring a new experience and the trend of dimensionality reduction. It can be said that China's best craftsman spirit is in the Internet industry. Their grasp of the human-computer interface can be said to be a deep understanding of human nature and tempered repeatedly. When a large number of such personnel enter the traditional industry, that is, the day of great upgrading of the traditional industry. A small table lamp of Xiaomi department will go to Germany to win a red dot award. This experience idea is a new impact. However, their weaknesses are also very obvious. Although it is strong in design, its reliability is uncertain. The design can break the front door, but the back door must be guarded by traditional manufacturing. This is where water and oil are made in China.

To move towards the medium and high-end value chain, made in China needs a dual driving force, both quality consumption and equipment upgrading. With the upgrading of quality, they drive the upgrading of the supply chain. The new quality thinking bears the brunt.

From Dr. Bei's toothbrush and shutila trolley case, we can see that it will be difficult to actively upgrade China's supply chain. One is unintentional and incapable of tackling key problems, and the other is indifferent to quality awareness. This makes shutI, who has broken out of the brand, become a lonely locomotive. It is dragging its own burden and moving forward hard. First of all, Shu put forward the slogan of "guaranteed compensation for damage in three years", which has never been heard in the industry. However, this pioneer approach forced those leading brands in the industry to keep up. As long as the enterprise makes a commitment, the industry is bound to upgrade. Because it is difficult for a brand to convince those accustomed to the low-end supply chain to follow. Only when there is demand in the whole industry will it drive the collective upgrading of the supply chain. This is a difficult transition period. For a leading new domestic product, we should not only build a brand, but also build an ecology. This is a dual mission. It is really difficult for a small enterprise. But it is at such a moment that new quality thinking is the most important time to lead forward.

As long as the new domestic 2C brand can rise, it will force domestic 2B enterprises to gradually keep up, forming a double spiral upgrading situation of "high-quality consumption" and "high-end supply chain". This is a fishing rod effect. The hook pulls the fishing rod sleeve section forward gradually, and the rear section keeps up step by step. The double helix upgrade will be an epoch-making victory for China's new quality thinking.

Domestic and international double circulation, double upgrading of consumer equipment. The double cycle has built a fully interactive market pattern, and what it corresponds to and gives birth to is the double spiral upgrading of China's manufacturing system: high-quality consumer goods and high-grade supply chain. First 2C then 2B, a line of grasshoppers rush forward, which is a process of synchronous rise. In China's single large market with a population of 1.4 billion, there are 300 million or 400 million middle-class people. No matter which market segment they hit, they have the opportunity to make high-quality products.

Notes: China's quality should hold its head high

The rise of domestic brands is not uncommon. These manufacturers who win by quality leave a deep impression on people with their grasp of experience quality. This is the beginning of the high-quality story conference made in China. The quality community needs a new voice to cheer for them.

On the factory side, China, as a huge world factory, must have accumulated a lot of practice on site, which needs to be excavated. In terms of the development of quality engineering theory, there has been no significant progress in decades. However, the integration of digital technology is giving people new imagination. China is just the most enthusiastic place for digital technology. How to refine this practice is also a key link for China's quality to move towards the international stage.

Many products made in China, although there are many unsatisfactory places. However, many products have paid great attention to user experience design and are close to people's use habits. The sweeping robot was first produced by iRobot, an American company. But now the market value is only 1 / 10 of Xiaomi's stone robot. IRobot is now on the "quality cliff". Its function and reliability are good enough, but it can not break through the experience. On the contrary, it is later broken through by the stone robot. Through the introduction of optical radar, AI and other technologies, and by adding scanning family maps, the stone robot has greatly improved the user experience and won in one fell swoop.

This is our time. New quality, re weighing the weight of user elements; New quality thinking reminds enterprise leaders to reshape a quality mind and let quality run into the chairman's office.

At such a moment, it is the node where made in China raises its head, accepts the embrace of users and the baptism of globalization, so that made in China can move towards the middle and high end of the value chain.

The content comes from the network/Knowledge automation, this website only provides reprint. The views, positions and technologies of this article have nothing to do with this website. If there is infringement, please contact us to delete it!

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853