-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2394

Q: made in China, does it need to reshape the quality system?

Twenty years after China's entry into WTO, made in China has integrated into the mighty torrent of globalization and accumulated fruitful results. Now, we can also see many unfavorable "international countercurrent" factors. "Globalization" is the seamless use of global resources, while "internationalization" is a parallel exchange under national borders. The concept of decoupling is a manifestation of the countercurrent of internationalization. The global supply chain is also fighting against the principle of economy, forming a sign of standing in line and selecting sides, which brings a new challenge to made in China's desire to climb a new peak.

Quality is to create eternal melody. Made in China, at such a juncture, we need to re-examine the quality thinking in order to walk through this barrier. However, for entrepreneurs, the topic of quality is too outdated. It seems to have become a matter for middle-level cadres and even on-site workers.

On the contrary, Chinese quality has always been a pot of raw rice. China's quality system has not been able to correct the source and clear the source and establish a positive base. China's industrial system was founded on 156 aid projects of the former Soviet Union. These projects distributed everywhere, just like the plum blossom pile, established the structural system of China's industry. In the context of "quality" under the former planning system, the understanding of users is almost zero. As for the relationship between design and quality, it is rarely mentioned. During this period, quality is often regarded as a fashionable or progressive example.

China's quality system construction, in line with international standards, began to follow ISO international standards in 1987, and then there was the official version of ISO9000 in 1994. In 1996, when the Ministry of machinery launched the three major campaigns of the machinery industry, "product quality turnaround" ranked first. However, the Ministry of machinery was dissolved in 1998. The quality system is like a pot of charcoal stove knocked over in a hurry. Mars goes everywhere, and the system can hardly be said to be complete. This is a trend of making fast money. It is the acceleration era of China's manufacturing industry. As long as there is equipment, there are almost no manufacturers who do not make money. ISO standard has basically become a solemn and empty prop, just like the same couplet to be posted at the door of the house every new year.

After 2001, China's quality is to follow the big ship of globalization, go with the wind, open mountains and build bridges with water. Too many enterprises need ISO Certificate to prove that the quality process has met the specifications. But in fact, in many enterprises, this is just a timely backplane. As soon as the members of the standards certification group left, their fate was like the back plate of the summit, which was withdrawn immediately after the meeting. In any case, life is only three or two days.

During this period, some excellent manufacturers, including Huawei, Foxconn, Haier and Gree, have made great achievements in quality. However, this only represents the rise of individuals, and the quality thinking of a group has not been formed. The quality system is not a simple hardware superposition of quality infrastructure such as standards, measurement and certification, but the sum of soft power of industrial culture such as industrial thinking, quality awareness and quality honor.

In the factory, the category of quality system is more worthy of consideration. Materialization in form is not the equivalent of quality thinking. Kanban in Japanese lean production seems to be just the material connection between the upper and lower processes. Standing next to the machine, the previous process sent a magical basket to the next process, which was just full of all the parts needed by the latter. These appearances are not the essence of the quality system at all. The real significance of Kanban is its contribution to economics. The next operation is the "user" of the previous operation and provides cash for the previous operation. The handover of defective products is the way to make money for those who are behind. Only by instilling the awareness of cash flow (which is the foundation of the enterprise's survival) into every post in the production line, can such a quality system be real and effective.

The greatest achievement of American quality master Deming in Japan is that a set of system principles has been widely accepted. In 1950, he put forward the view of "making production a system" in Japan, which hit the key of Japan's early naive manufacturing. Only when the production system is stable can we talk about the later lean system or Toyota production mode. Japanese managers and engineers, in addition to manufacturing, built a set of quality system, and then implemented it as a day for 30 years. That's why made in Japan really won.

At present, where internationalization is surging against the current, made in China needs an improvement in group quality. "New quality thinking" is about to emerge. It is not only blessed by new digital technology, but also deeply popularized the quality system to re melt the immature quality mind made in China.

Second question: can the craftsman spirit solve the quality problem?

There is a deep-rooted misunderstanding in China's manufacturing industry, which always attributes quality to craftsmanship. This is not complete, even close to a kind of moral kidnapping.

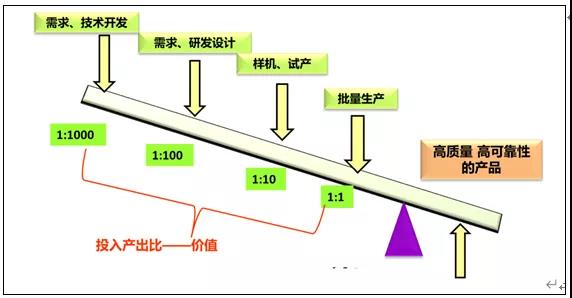

Craftsmanship does not guarantee quality. Hard work does not guarantee quality, nor does enthusiasm ensure quality. When the quality control means deviate, too much effort will cause more waste. Quality is generated by a system. It is a chain lock, but each participant has only one key. The highest value is the upstream. Design determines the inherent quality and reliability level of products, and determines the cost and vitality of products. Based on the understanding and accurate interpretation of the requirements, the design team endows the products with high quality and high reliability (high-quality gene) while minimizing the cost.

Fig. 2 quality lever diagram

(source: Thank sandrand for providing)

In the manufacturing process, the on-site personnel (engineers and operators) focus on the quality fluctuation of the processing process as much as possible, even if they take strict precautions and work hard. Compliance with product specifications does not ensure quality; Zero defect is not quality, these are appearances. Sometimes they are a reflection of quality, but most of the time they are not. Craftsman spirit can only achieve limited remedy in the workshop, but can not exceed the quality expectation of the design. No matter how skillful a craftsman is, he can't change the congenital defects of design. The quality of a product is its brilliance and health. Reliability is the key.

From another point of view, craftsman spirit often has strong craftsman intuition. It is a master of experience and knowledge. They are used to working at their own pace. If one assignment takes more time, another assignment will remember to make up for it, that is, they adjust their own homework time. However, this does not meet the qualitative and quantitative certainty requirements of industrial production, resulting in uneven quality. When naiichi Ono implemented the "Kanban" management method in Toyota, the foreman would count the time behind the employees with a stopwatch. This angered employees with a strong craftsmanship spirit. However, the improvement of quality consciousness is the struggle with human nature. This is why simple quality principles are often difficult to implement.

Craftsman spirit has the sensory impact of shocking the soul and moving the viewer. It is also the pursuit that the industrial site will not give up. However, if quality is regarded as the lack of workers' professionalism and the lack of craftsman spirit, it is an outdated world outlook. Moreover, it makes all managers breathe a sigh of relief and directly shirk their responsibilities.

Question 3: can the quality department carry the black pot of quality?

In an enterprise / factory, all kinds of quality slogans will be pasted on the wall, but will these slogans really hang in the hearts of managers?

You can compare it. As a tool of informatization, it is easy to invite the general manager to "ERP is the number one project". Quality, as one of the three pillars of enterprise survival (QCD quality, cost and delivery), has never shouted "quality is the number one project".

The reason is very simple. IT system is a software program, which requires logic self consistency. If it fails at one point, it cannot be bypassed, and all departments will notice the existence of this obstruction. When the information flow obstruction becomes larger and can not be solved by each department, the boss must be alerted.

Quality process is not a closed loop by nature. It has many ways. If a point is blocked, it will go around and no one will notice. A supervisor who is trying to catch up with the production progress will not stop the machine for maintenance even if he finds a small fault. He needs to meet the production standard within the specified time. The possible result is that the machine that was only a minor disease this month will become a serious disease next month, seriously affecting the product quality. The supervisor has no fault in one part. Only in the system can he find greater waste. The loopholes behind quality defects can not be made explicit, so it is difficult to disturb the leaders of other departments, let alone the leaders. Therefore, it is difficult for the quality department to have the courage to say to entrepreneurs that quality is the number one project. In this sense, quality is the easiest to be fooled. All staff participate and screw up the quality. In other words, the quality department is the biggest black pot in Chinese factories. The quality department will be responsible for the defects of R & D and design, supply chain procurement and errors in process instructions. Minister of quality is really a burden bearer of Mount Tai.

Dai Ming has always believed that quality is the business of big leaders of enterprises. In his opinion, the "quality department" department has few people and is simply unable to undertake the important quality task of an enterprise. "Quality is the number one project" and even the "board project" need the persistence of the number one of the enterprise, and the quality problem must become the topic of the board meeting every year.

In the view of the Japanese, the key success factor of continuous improvement is the so-called "on-site and on-site", going to the scene, using physical objects and checking the facts. These three constitute the technology of Toyota production system, but business school graduates are not interested in these three. Managers trained by business schools pay attention to financial management and use quantitative methods to look at problems from the perspective of profitability. This is a defect of narrow vision, just like a hammer sees everything as a nail. In a sense, a general manager with financial background is often the biggest obstacle to quality.

Made in China, we need to return to the quality thinking of "quality is the number one project". Although very traditional, it is still very novel for many Chinese entrepreneurs. The industry also needs to refresh the brain circuit, just as the browser needs to clear those cookies filled with history records and update the quality thinking.

Fourth question: is low cost necessarily low quality?

Twenty years after China's entry into WTO, its products have swept the world. If the quality does not pass, it is impossible to achieve globalization. Low price is certainly one aspect, but if the quality stability does not meet the standard, no matter how low the price is, it can not be recognized by the international market. This means that the quality made in China must have reached a considerable level.

In the world's leading pneumatic automation company with a long-term prosperity in the Japanese stock market, the enterprise's winning quality concept is impressive: the first sentence is that quality is supreme; The second sentence is to win at low cost. 40% of the products supplied by this Japanese brand worldwide come from China. For some valves, it reaches 90%. If the quality is not good, why can we do the world? Made in China is no worse than made in Japan. The company believes that low cost is a competitive advantage. Many domestic enterprises are even ashamed to say "low cost".

Deming has long predicted that both quality and cost can be achieved, which can not only create high-quality products and services, but also reduce costs.

How is it done? Quality runs through the manufacturing and design process, and the design quality is different from the manufacturing quality. Design quality involves performance, safety, reliability and customer experience. Manufacturing quality is the process control of manufacturing according to the design quality requirements, which is the top priority of field workers.

High quality first depends on the enterprise quality planning. There are both quality assurance qa system and quality control QC system, which are different. Qa quality assurance is to plan and build a system to fulfill commitments to customers; QC is the process of realizing quality assurance with minimum investment and controlling cost. The more sound QA is, the better, but QC should have the best path and pay attention to management and control efficiency. In short, QA is the biggest system design quality commitment; QC is the minimum cost input to ensure that the manufacturing quality will not deviate from the design quality. The scissors difference between the two implements the "low cost to achieve high quality".

It is very important for designers to master optimization methods such as parameter design proposed by Mr. Taguchi. Under different combinations of different design parameters, even if a third-class component is used for a device, the result is better than that of the first-class product. Russian military products are not sophisticated enough in chip and electronic control, but they often rely on system level optimization and have achieved amazing results. In the aeroengine control system of military third-generation aircraft, Russia has completed the chip electronic controller adopted by Britain and the United States by using hydraulic and mechanical control. Tianji horse racing, although each track is the second best, but the combination can form a systematic victory. This is the essence of optimization and the proof that low cost can also have high-quality products. Parameter design was widely used in Japan in the 1970s. It is a cutting-edge method that designers must master, contributing 5% to the GDP of the national economy, which is the real more, faster, better and more economical.

Q 5: does China's manufacturing industry need quality heroes?

The peak of American manufacturing basically dominated the whole 20th century, summarized many quality theories, and also exported many quality masters. The earliest can be traced back to Bell laboratory engineer Shewhart in the quality statistics chart, followed by clausby's free quality, Feigenbaum in total quality management, and Smith, the father of Motorola engineer Six Sigma.

The rise of made in Japan after World War II was accompanied by the appearance of quality heroes. During this period, Japanese quality Corolla was generously given to two Americans: Deming and Juran. Although in the pilgrim's gift, the sharp satirical author moved out three other naval engineers as the Enlightenment of Japanese quality and mocked Deming's rigidity. Even though the United States has benefited a lot from Japan's Toyota production mode, American academic circles are still used to making small moves with their own strong culture, implying that Japan's quality culture is just the re cutting and dyeing of robes borrowed from the United States.

Under the guidance of the Japan Science and technology alliance just, Dai Ming was invited to Japan to explain how Americans use statistical quality technology to improve the production efficiency of military products. Dr. Dai Ming has been guiding quality management in Japan for nearly 40 years since 1950, and almost every year in the first 20 or 30 years. Almost all the early Japanese operators contacted Dr. Deming and devoted themselves to practicing Dr. Deming's quality management philosophy. This 40 year long worship of quality has laid the foundation of made in Japan.

Another famous quality master is Juran of the United States. He arrived in Japan in 1954 and poured a ladle of oil into Dai Ming's hot quality pot, which exploded the heart knot of Japanese industry. Juran held various seminars for middle and senior managers, successfully shifting Japan's focus from management to factory workers. Through close dialogue with workers, made in Japan has made important achievements in technological innovation.

These brilliant American quality masters have successfully enlightened the quality consciousness of Japanese manufacturing industry. But the stories of big people often cover up many small efforts.

In the two decades from 1950 to 1970, the Japan Science and technology alliance provided intensive training courses for more than 14000 engineers, and quality statistical methods were widely penetrated into the brains of these engineers. To the surprise of Japanese operators, this effect was almost immediate.

In this crucial year for Japan's manufacturing take-off, Japan has played its characteristics as "the best student in the world". In the decade from 1955 to 1965, the Japanese Productivity Commission sent 6600 industry representatives to the United States to study productivity. After returning to Japan, these people published various discoveries and feelings in the form of papers, with up to 40000 pages of records. The most venomous eyes should belong to naiichi Ono who carefully observed the Rouge River factory of Ford. At the automobile assembly line where thousands of people make pilgrimages every day, Ono keenly identified the defects of Ford's mass production, shifted mass production from mass production to small batch production, and opened a unique Toyota production mode.

However, the rise of Japanese quality cannot be attributed to American enlightenment. Even Dai Ming, who returned to the United States after Japan's canonization, basically failed in his knife practice at Ford. Although the president of Ford was willing to listen to the opinions of the agent, he failed to fundamentally change the management culture of Ford. The quality of the United States has improved as a result. The 2mm project aimed at improving the body size and quality launched by the American automobile industry in Detroit was still a great success. Deming's enlightenment is meritorious, and the internal causes of Japan's rise in quality play a greater role. Quality is closely related to culture. It is not logical to pile achievements on one or two people. However, the cognition of human groups always needs a superficial emotion to express. What has happened is best represented by a dramatic event or an iconic figure. That's why Deming became a God in Japan. If it weren't for him, there would be someone else.

There are also epoch-making figures in Japan's quality circles. The systematic Toyota production mode of Ono Naiyi Institute is undoubtedly the most fierce shell against production waste in industrial history. The artillery fire has tempered the quality consciousness of log manufacturing to the greatest extent. The waste caused by quality defects is one of the so-called "seven kinds of useless work" of Ono. In fact, Ono is not alone. The grumpy Ono brings out a group of disciples with the same character, which is passed down from generation to generation, including Haojie (nickname hot, angry at the waste at the scene), Lin Nanba (big devil), Youshan (Little Devil), etc. When the disciples saw the master, they walked tremblingly against the wall; So did their own disciples. The battle of Toyota's production mode in Japan is protracted, and it has burned 52 Toyota factories from Japan to the United States. This is done by "a tyrant with a group of angry believers". Behind irritability is fire like enthusiasm. Without firm faith, this quality battle of more than 60 years can not be completed.

Another epoch-making figure in quality engineering is Xuanyi Taguchi of Japan. Taguchi applied the experimental design method to the product design of manufacturing industry for the first time, so that "uncontrollable factors should be insensitive, while controllable factors can be sensitive". Taguchi will burn the quality position of Ono Naiyi in the factory to a more front-end link. The quality gate has been moved forward to the design field. The three designs proposed by Xuanyi Taguchi: system design, parameter design and tolerance design are widely accepted. Among them, parameter design has become a magic weapon for Japanese enterprises to achieve high-quality reliability at low cost, and Japanese products have also become synonymous with high quality and low price. After that, Taguchi method traveled across the sea. Mr. Taguchi was invited by the three major American cars to "pass on the classics and send treasures" in the United States. When he was alive, the statue stood in the automobile Hall (this is the first person who lived in when he was alive), and was transformed into robust design by American scholars. So far, it is still the most important method in the field of quality reliability design.

In China, there are few people who can be famous for quality theory. If we want to eat the rice of quality theory, it is the rice bowl of the poor. If there are no rice grains, we will starve to death. This is very mismatched with the world's largest manufacturing country. What can be compared is the group image of "entrepreneurs". In the last three decades, "entrepreneurs" have perfectly come to the front stage and become an important group pursued by a generation. Like Gree Electric Appliance and Fuyao Glass, there is almost no advertising. When the face of the family is the largest flow irrigation machine. Chinese entrepreneurs have become the idols of the times, which is the prosperity of a big country. However, it is surprising that "quality home" and "quality master" did not appear.

Since China's entry into WTO in 2001, China's industry has experienced a long bull market with rapid development for 20 years, while the quality sector has become a long bear market with little water. Behind this anomaly lies the secret mechanism of made in China climbing to the medium and high-end value chain. It may be inferred that at present, there are no benchmarking figures in the quality industry in China, which just shows that the quality culture is not mature in the manufacturing industry in China. The industry has not realized that they need such quality heroes to show the great magnetic field of quality. The pointer of the times is still like a young Star chaser, vigorously chasing the new technical concepts of intelligent manufacturing, industrial Internet and 5g.

Question 6: who is the mother of quality?

Where does quality begin? The answer is often unexpected. In short, quality starts from the designer's creativity, and design is the mother of quality.

Taking machine tools as an example, there is a huge gap between China and Germany. Naturally, it is needless to say. However, it is incredible that the distance of this gap is not clear in the machine tool industry with precision as the king.

The reliability of Chinese machine tools has been criticized by the industry and has become the biggest weakness in quality. The reliability of machine tool is mainly three characteristics (static characteristics, dynamic characteristics and thermal characteristics) at work, while the cutting performance of machine tool mainly depends on the dynamic characteristics. It is this dynamic characteristic that is almost ignored by the domestic machine tool industry. The root cause of this seemingly "negligence" actually comes from China's lack of research on basic mechanism and insufficient accumulation of engineering database on machine tool characteristics, so it is impossible to calibrate these size models correctly. The lack of engineering experience and the support of industry common technology is a major defect in China's machine tool industry.

In Germany, dynamic characteristics are the key consideration in machine tool design. In the German machine tool industry with rich design and manufacturing experience, there has always been strong support from various experiments from universities and colleges. The machine tool Institute of Stuttgart University in Germany has tested dozens of machine tools one by one, with more than 200 measuring points for each machine tool, forming an internal guide for machine tool design in Germany. The technicians of domestic machine tool enterprises basically have no concept of the dynamic characteristics of machine tools. When designing machine tools, they often pay more attention to static characteristic indexes such as positioning accuracy. The quality of medium and high-end machine tools under this concept is naturally not easy to be reliable.

However, it is surprising that China's machine tool industry has never had an engineering parameter database of foreign machine tools. It basically relies on experience for key parameters related to quality, such as rigidity and frequency. The design concept basically stays at the level of thirty or forty years ago. Moreover, even if we know which parameters are important, there is a lack of measurement and detection methods. This makes the machine tool industry, which has been faltering for more than a decade, have a tendency of self contraction. Of course, there are silent breakthroughs. A professor from Shanghai University of technology, who has cooperated with the German machine tool industry for more than 20 years, has established a measurable design concept and measurement method, which will greatly promote the dynamic performance of the machine tool.

In order to change the backward situation of China's machine tools, the first priority is to turn over the design concept. Without the guidance of design thinking, even if the short board of parts is supplemented and the task of strengthening the industrial base is completed, the whole machine is still not built well.

The same is true of aircraft design. After Airbus took over the bombardier aircraft in 2019, it transformed the original C series into a220, but this 130 seat aircraft is basically the same as the number of seats of Airbus a139. Why still get on the horse? Because A319 (130 seats) is a shortened version of A320 (150 seats) basic model. Its advantage is low development cost, but its disadvantage is that the basic structure weight of each passenger seat is not as low as that of the basic model. Just like the GL8 business class with 7 seats, the 10 seat basic model of Koster can also be changed to 7 seats, but the operating cost is completely different. Shortened aircraft are flying with some dead weight on their backs. Big horses pull small cars, and the cost is very high. Since the a220 is designed to directly specialize in market segments, it will make A318 / A319 and other models unable to compete.

These details are an eye opener to the product competitiveness brought by design differences. An A319 aircraft weighs nearly 60 tons, but it will be careful because of 20 seats, push back the design source, and even reintroduce the model.

Apple's products are amazing. Its quality feeling always makes users feel strange. Behind this is the designer's extreme thinking. Every time Apple designers design, it can be said that they have a problem for the global manufacturing industry. When Apple mobile phone uses aluminum alloy shell and needs mirror processing, almost no machine tool industry in the world is ready. This design concept pushes manufacturing to the limit, but surprises users. Hongguang mini electric vehicle of Shangtong Wuling, as the first model in new energy sales in China, has sold more than 270000 Hongguang miniev in 270 days since its listing in May this year. The design concept behind this is the real king. Firstly, it preset the goal of "making money without subsidies" in advance. Secondly, it decisively switched its positioning from old man music to youth fans during the test run. Sales come from the deep listening to users and the magic pen of designers, which is the highest level of quality.

Design thinking determines the height of the product.

Q: is high quality expensive?

When I visited the Japanese factory, my biggest feeling was that the factory was old. Whether it is the PLC production line of Mitsubishi Electric or the machine tool factory of Okamoto surface mill, the equipment is often not advanced. The site was clean and the staff were very focused. Look at modern and brand-new machines. There are many workshops in China.

This problem is not a new phenomenon today. In his early years, Deming pointed out that many automation and new machines are the source of low quality and high cost. In Toyota's production site, we rarely rely on the most advanced equipment, but give full play to the on-site employees to eliminate useless work and waste by "focusing on wisdom" in the form of team.

This means that new equipment investment is often the most clumsy way. Many factories believe in automation equipment and believe that technological upgrading can significantly change quality. Nagichi Ono's most annoying idea is "as long as you import new equipment, you can improve efficiency". No money is Ono's purpose. American quality master clausby said dryly, "quality is free", which even turned into a book. At the factory site, using your brain can greatly improve the quality and reduce the cost.

How to achieve with the lowest investment and achieve the ultimate, you can achieve the highest profit. This is the basic mechanism of Toyota's TPS production thought, which takes care of the manufacturing capacity in the palm of the hand. There will always be waste in manufacturing, so manufacturing is only better, there is no best. Minimizing investment can maximize profits.

Relying on equipment is often a lazy political thinking. Quality is thinking first, organization second, and technology third. Breaking through the quality trap with new technology is just a fig leaf for managers' quality laziness.

Q 8: does China's quality need the reflection of the times?

In the backward state of manufacturing in any country, we need to reflect on the quality in order to catch up with it in great strides.

The United States made a profound comparison of the quality of Japan in the 1980s. At that time, many manufacturing markets in the United States, such as automobiles and electronics, were being eroded by Japan. In particular, the automobile industry, which the United States is most proud of, has also been rampant by Japanese Toyota and Honda. In 1970, Americans bought almost all the cars produced in Detroit; In 1990, Japanese cars had sold millions in the American market. Honda, Toyota, Nissan and Mazda have firmly established themselves in the American market.

This is a great harm to the self-esteem established by Americans after World War II.

If Japan can, why can't we? NBC TV station of the United States issued the soul torture "quality question" in 1980.

In order to reverse this prejudice, at that time, American industry and scholars believed that it was necessary to confirm the rise of made in Japan and salute Japan to truly improve the ability of made in the United States. NBC's report came into being against this background: it is committed to introducing quality masters to professional managers in the United States.

NBC's big report on "quality revolution" describes in detail how Japan follows Deming's "continuous improvement" proposal to "treat manufacturing as a system" rather than partial piecemeal improvement. This 14 hour documentary describes Deming's quality methods and views in great detail through manuscripts, interviews, case studies and application presentations.

It is also a representative of low price and low quality. How can Japanese goods enter the U.S. market like Zhongtian? The United States made a deep inquiry, and was surprised to find that there are many Americans behind the quality of Japan. This discovery has made Deming, a quality master, a blockbuster. It is no longer a flower inside the wall and a fragrance outside the wall. Made in the United States, it starts from following Deming's concept.

GM embarked on the road of cooperation with Toyota. Toyota doesn't seem to like excessive automation, but always gives full play to people's value and puts it first. This deeply affected Roger Smith, President of general motors, who was almost immediately infatuated with Japan's Toyota system. GM abandoned many automation projects and focused on lean management. In the new "Saturn" automobile factory, only a few limited production processes are set up, and the workers are generalists, rather than the fine division of labor of Fordism, one person often only does very limited processes. The treatment of workers has also completely broken the hourly salary system and adopted a link with output and sales. In short, GM tries to learn a new production system by establishing a single Japanese style factory.

Ford performed even better in this regard in order to learn from Japan's Mazda production system. Ford not only bought a certain proportion of the other party's shares, but also hired Dai Ming as the company's consultant. Unlike general motors, Ford does not require changes in individual departments, but adopts Deming's perspective of "manufacturing is a system" to promote the whole enterprise to the goal of lean production.

It took Detroit carmakers a generation to really understand the lean production worshipped by the Japanese. Then, with the rise of Dell computer adopting this production system, it has become a common practice to learn from Japan and master the essence of production, which seems to have become the standard configuration of all manufacturing industries in the United States.

From the "question of quality", the vitality of the whole manufacturing industry in the United States has been stimulated. Made in China must also establish its own quality system. Only through a comprehensive examination can we better understand the plight, defects and rebirth of China's quality. Made in China, quality problems can be said to be piled up, but the solution is basically to let Yugong move the mountain. Both lean system and quality system are scattered by some small and micro consulting companies. They stood in front of a large granary and picked up a little quality residue like a chicken pecking rice. Without the awakening of the national awareness of quality, quality is just a puzzle game.

Made in China needs a system, which needs to wait for a grand quality revolution, and before that, it also needs a grand national quality reflection. Only by focusing on quality can we be more confident and climb high slopes.

In his book new economic outlook, Dai Ming strengthened the key proposition that "quality is the foundation of the new economic era". At present, made in China is ushering in a new critical moment. When can we have a profound "quality torture"? The Chinese manufacturing industry needs to be determined to answer such questions with practice in the next 20 or 30 years.

Nine questions: quality thinking, have you turned the page?

In China, the quality problem is the most old-fashioned. This is almost a dead composition problem. No new ideas, no surprises. Talking about quality thinking is like a strange thing.

However, even in a company like Toyota that began to consider quality more than 70 years ago, the long battle continues today. The disciples and grandchildren of Naiyi Ono are still struggling at the scene in high spirits. This means that quality is like an on-site God who can't please anyone and wants to pay tribute every day.

The situation in China makes the new quality thinking more urgent.

With the rapid rise of China in recent decades, people have seen a rapidly evolving consumer market. Behind this is the progress of manufacturing supply chain. Chinese factories are also changing dramatically, releasing completely different demand on the factory site.

There are few new markets in Europe, industrial products are relatively stable, and the on-site change speed of factories is relatively slow. However, the Chinese market evolves too fast and has strong requirements for new products.

Such as the rise of smart phones, in the Nokia era, mobile phones only have communication function. The smart phone has greatly increased its functions, forcing process innovation, which has completely changed the supply chain demand of the factory. 90% of the world's mobile phones are manufactured in China, which creates a new opportunity for a great leap forward in the supply chain. The original apple mobile phone gave the machine tool industry a problem that had never existed before: it was similar to the accuracy requirements of aircraft wings, but the production capacity was larger than the batch of cars. What kind of machine tool is this? The humble Beijing Jingdiao seized this opportunity to develop rapidly in 3C electronics. Previously, as an advertising engraving machine, precision carving was not paid attention to by the machine tool industry. Similarly, the upgrading speed of 3C electronics is very fast, and the production line is required to be replaced quickly. As an automatic pneumatic component, the previous two-month supply cycle was enough, but now it takes two weeks to deliver. All these have left a magnificent opportunity for machine upgrading to the industrial site. With the operation of a new business form, the factory needs to keep up with drastic changes. Made in China is facing such dynamic demand.

It can be said that the rise of new domestic products in recent years, whether it is Xiaomi ecology, bubble Matt blind box, Dr. Bei toothbrush, Weilai electric vehicle, or Xiyin, a women's e-commerce ranked second only to Amazon, is backed by a strong supply chain and quality assurance. Behind every excellent product is a strong supply chain and a set of quality assurance system. This is the unique soil made in China and the flower of quality.

Similarly, for the evolution of other long manufacturing categories, the new energy industry is simply falling from the sky. In ten years, the photovoltaic industry has completed the global industrial elimination and established the dominant position of made in China. The power battery, which also took ten years, has also been in the forefront of the global industry. Although Suntech and Yingli have become martyrs in the past, Longji photovoltaic and Ningde era have become super enterprises. The new forces of car making have also thrown off their burdens and made every effort to attack the track of old enterprises with only 100 years of qualification. Among the elephants, there are small dinosaur like hunters.

At the same time, the digital technology of the factory also makes the digital quality usher in a new practice. Digital technology has brought changes in the form of quality data. In the past, it was measured with spiral micrometer, caliper, etc. after measurement, it needs to be recorded manually. Now they are all electronic. Many calipers are recorded automatically and transmitted wirelessly to the computer. Real time data storage, abnormal judgment and summary are directly entered into the measurement database.

The form is also changing. For example, the quality recognition technology of camera can replace caliper for automatic acquisition and shape recognition. What is more important is the substitution of some high-intensity jobs. As the world's largest PCB manufacturer, China accounts for about 90% of the world. PCB boards generally use automatic optical inspection equipment (AOI) machines, which are often followed by 3-5 people for re judgment. There are 6-8 AOI machines in a production line, which means that the number of quality re judgment is as high as about 30. This boring post makes the factory face a serious shortage of people. However, the defects of PCB board have unique industry characteristics. It often has an obvious tree cause relationship with technology and manufacturing process. Therefore, an artificial intelligence algorithm testing company from Beijing can better complete the certainty of PCB yield through AI algorithm with the help of machine vision pictures and reduce personnel by more than 30%. In addition, a shipyard established a material heating model through the flow characteristics of welding materials, so as to realize the process intelligence of weld quality detection and better improve the weld quality. Similarly, in the machining site, if software is equipped to detect the stability of tools and equipment through size on site, the workpiece quality will be greatly improved. It can not only save man hours, prevent mistakes, but also improve efficiency.

These phenomena have never been met by quality masters before. Dai Ming's most worried about "falsification of data due to fear" and "false numbers if there is fear" will cover up the signs of quality deterioration, which has completely disappeared. In fact, after the design-oriented Six Sigma DFSS was put forward around 2000, there has been no great breakthrough in quality theory in the past two decades, which is the time when the Internet of things and digital technology have been rapidly promoted.

The greater quality challenge is that quality has entered an era of experience economy. User satisfaction formed by experience has become the most powerful cornerstone of quality. Tesla electric vehicle is in J.D., a well-known automobile consulting organization. Power ranks at the bottom of the global quality ranking, and extreme events such as poor braking also haunt Tesla, but these still do not affect it to become the overlord of global electric vehicles. This means that users' awareness of product quality is adding a new dimension. The open central large screen, flattering self retractable handle and automatic hatchback door, which were previously only experienced by luxury cars, have changed users' attention to quality. As a manufacturer, we must understand this new "experience quality". Traditional quality concepts such as consistency and reliability are still very important, but new variables are also forming challenges.

Digitization is making the concept of quality management vivid and rich. In the factory, it can make the wolf abnormality manifest to the greatest extent, and can handle it quickly and even start the plan automatically. The earlier and faster the discovery, the smaller the quality loss. Digitization has done this, but the quality theory has not kept up for the time being. As a big country of digital economy, China has ushered in the best moment of quality innovation. New quality thinking is the call of the times. The base of Chinese consumers and China, as the world's factory, naturally have the fertile land for the birth of "new generation quality", but whether it is born here needs more efforts.

Question 10: is there a culture made in China?

Let's start with made in Japan. Why can Japanese quality culture prevail all over the world?

Many words, such as Kaizen and pokayoka, are directly absorbed into English.

On the one hand, of course, the quality of Japanese made products has passed the standard. On the other hand, Japan's large-scale products such as cars, household appliances and cameras in the past few decades have indeed left a deep impression on the world. Conversely, why is made in China often connected with low quality?

In fact, the reputation of a country's manufacturing is related to many other factors besides the product quality itself. Quality culture is crucial. In Japan, a kind of management consulting company is very popular. Their job is to "tell stories made in Japan". For example, the Central Industrial Alliance of Japan, which first started from the Toyota department, many Toyota suppliers, such as retired middle and senior managers such as electric equipment and Aisin precision machinery, and quality management experts, will form an advisory team to help small and medium-sized enterprises implement quality actions on the one hand, and vigorously disseminate Japanese quality on the other.

The staff of Japan Energy Efficiency Association often stay in enterprises, do on-site follow-up interviews, learn from enterprise experience, listen to Japanese quality stories, and then spread them to the outside world.

Similar to the magazine of business administration, it summarizes a lot of enterprise experience and spreads it everywhere. This means that Japan has a "quality speaking singing group" to sing the song made in Japan. These quality consultants, like field reporters, observe, record and spread the stories of the fighters when the front-line soldiers are fighting.

This means that made in Japan, surrounded by an atmosphere of quality upward. Industrial culture, accompanied by manufacturing. Many scholars have theories, such as zero defect rate and abnormal management, and then choose 4-5 to observe how entrepreneurs implement them in production activities.

If Japanese quality culture is a series of films such as 007, it will last for a long time, then Americans, as quality screenwriters, have made great contributions to telling stories one after another. Dai Ming and Zhu LAN made and spread the seeds of quality concept for Japan after World War II and grew into fruit trees, which flourished. In the 1990s, Americans Womack and Jeff liker picked these fruits and swept the world with the concept of "lean". In 1989, MIT launched the international automobile research program. Researchers once again aroused great interest in the high efficiency of Japanese automobile factories. The most profound thing is that each factory in Japan can receive 123 suggestions from workers, while the United States and Europe can only get one suggestion. All the forces of change seem to come from the scene. In 1990, lean: a machine that changes the world, a masterpiece based on this research and based on Toyota's production mode, was born - lean production, which has swept the world since then. The United States has thoroughly entered the era of catching up with and learning from Japan.

These are the iconic trees of Japanese quality. In fact, countless energetic weeds have been formed on the surface of Japanese industry, and the quality culture has been completely activated.

Made in China, in the era of globalization, actually suffered a great loss without the support of industrial culture. Foreigners are only exposed to Chinese products, and there are few formed quality ideas, impressive stories and thought-provoking ideas. Low cost, low quality and workers' bonus are the easiest hats for them. Because there are no stories and ideas on products that can hit their hearts.

The reason why the American factory, which is based on the factory of Fuyao Glass in the United States, has attracted much attention is that the management concept made in China is rarely displayed in front of Americans in such a shocking way. Putting aside the conflict of values first can cause a profound reflection on made in China, which is a great victory.

Made in China is facing a new upgrade, which is the soil that needs a lot of quality culture. The scene made in China calls for better factory writers. Our scholars and entrepreneurs turn a blind eye to the excellent manufacturing stories around us.

When it comes to the four kings of lean production system in the world, Toyota's TPS certainly ranks first. The SPD of Schneider Electric of France, energy and automation, the DBS production system of Danaher with matrix brand, and the Bosch BPS production system with diversified products are all veterans who are familiar with manufacturing. Their achievements in the production line have also greatly provided the brand reputation and virtually added points to the quality of the products. The rise of China's manufacturing industry has also spawned many experts on the production site, such as TCL and Jinfeng, who have their own set of good production systems. Unfortunately, the experience of manufacturing is far from enough, the concept of manufacturing has not been formed, and the brand has not been assisted.

Only by going deep into the factory and grasping the concept can we understand the profound insight into man-machine integration behind the semi automation pursued by manufacturing madman BYD ten years ago, and we can understand the idea of zero defects behind the "extreme manufacturing" proposed by battery giant Ningde era, Only in this way can we understand the impact of Shangtong Wuling, which has repeatedly presented the magic national car, on the instant amplification and manufacturing of listening to the voice of users behind the recent Hongguang mini electric vehicle volume crown in the world.

If a country's products want to walk in globalization, they need two legs: excellent products and cultural ideas. Without these good stories, Chinese products are lame in the global market. This is the sum of losses made by a country, and every enterprise is a victim.

Made in China seems to be in the dilemma of "having technology and no culture". Can't tell a story, rice without soup. Behind the quality myth made in Japan is not only Toyota's lean practice, but also the experimental support of Dr. Taguchi and other researchers, as well as a large number of propaganda choir. Their chattering voice has become a harmonious accompaniment of Japanese quality. This is a propaganda machine at work, and it is also a part of the industrial system. From factory case to story, from story to legend, from legend to culture, from industrial culture to industrial legend. This is the mental journey of an industrial power.

Notes: fit, rise up

Made in China is at the corner of the middle and low value chain to the middle and high value chain, and it is also an arduous climbing area. Quality breakthrough is the crucial engine. The previous rise of made in China has not experienced systematic quality thinking enlightenment, nor has it achieved vigorous quality transformation. Therefore, it is more necessary to face up to the quality belief and move forward. Made in China has always been disconnected from quality culture, or made in China has never been wrapped in quality culture. The body runs wildly where the soul can't catch up, and the creative spirit pants and falls behind the manufacture of goods. Now, it's time for the two to fit together. It's time for the new quality thinking with design thinking as the pioneer, traditional quality essence as the chassis and digital technology as the wheel.

At this time, made in China is very close to the plateau.

At this moment, we call for quality masters and new quality thinking.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853