-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2483

From the lack of original imitation to the normalization of innovation, from reverse engineering to in-depth basic research, and finally to higher industrialization, this is a common way to become a manufacturing power. In the early stage of development, the United States and Germany imitated the powerful manufacturing industry of the former British Empire, thus starting the process of building a country by industry. However, order and rules often follow the characteristics of time hegemonism. The pioneers are usually full of discrimination, criticism and obstruction to the later imitators. However, if we look at the process of each industrial power from weak to strong in history, imitation is like a phased adolescent migraine in the process of human growth, this disease can be completely cured.

Redefinition of labels

The enviable "made in Germany" label was originally an insulting mark imposed by Britain on Germany to show that this kind of manufacturing is a low-quality product. However, Germany made a late strike and simply reversed a discriminatory regional label into a global quality assurance. The story behind this can be seen from the chemical industry, one of Germany's advantageous industries, the process of German industrial development. The development of German industry mainly starts from the chemical industry represented by dyes. However, in the first 10 years of the dye industry, more than a dozen companies engaged in dye production and operation rely on imitating the dye production process in France or Britain. The earliest dye industry in Germany was controlled by the so-called "formula masters", who would not easily tell the secret formula. The enterprise can only obey the command of these recipe masters, and there is no way. Those who bring these alchemy like chemical industries into the modern chemical system are excellent German scientists and engineers. They launched the world's first real enterprise laboratory, extensively studied the color matching of various dyes in the laboratory, and entered the link of basic research. Scientifically grasping the progress of basic research made Germany get rid of the shackles of secret formulas in Britain and France and take the lead in creating modern chemical industry. German industry has also stepped out of the "adolescence" of imitation and started the journey of manufacturing a powerful country.

The internationalization of made in China began in the early stage of reform and opening up, and was carried forward after China's entry into the World Trade Organization (WTO) in 2001. From the initial incoming material processing and drawing processing, to later, with the improvement of manufacturing technology and technology and the increasing improvement of parts supply network, a large-scale imitation manufacturing system has been developed in a period of time. Mobile phones are the most obvious example. Waveguide mobile phone, which began production in 1992, started with simple assembly. Since 2000, it has won the domestic mobile phone sales champion for six consecutive years, becoming the first domestic mobile phone to beat foreign brands such as Nokia and Motorola. Although waveguide finally declined rapidly due to lack of R & D, and of course, former mobile phone giants such as Motorola and Nokia also fell later, its rise is a landmark event. It has created a way and channel to quickly market products. Although the waveguide manufacturing mode of "rapid listing and super publicity" is like fireworks in the sky, shining brightly but passing away, it has a profound impact on the subsequent development of made in China. The waveguide disappeared, but its fire was scattered everywhere. The senior management team from waveguide re established the voice mobile phone company for the European market. This brand is almost unknown in China, because it is hardly sold in the domestic market, and all products are exported.

Gray scale innovation crosses the international threshold: global design made in China

From 1980s to 1990s, an operating mechanism of global division of labor appeared. Wall Street's pursuit of greater profits has promoted entrepreneurs' infatuation with "asset light operation". An enterprise's focus on core competitiveness was regarded as a top priority at that time. A large number of businesses unrelated to core competence began to be outsourced, and the best division mechanism was found in the global industrial chain. As a hardworking and pragmatic country, China soon became an ideal partner in the global division of labor. With China's accession to the WTO in 2001, China's production enthusiasm and the potential of the labor market have been fully released. "Global design made in China" has become a tried and tested cooperation model of multinational corporations.

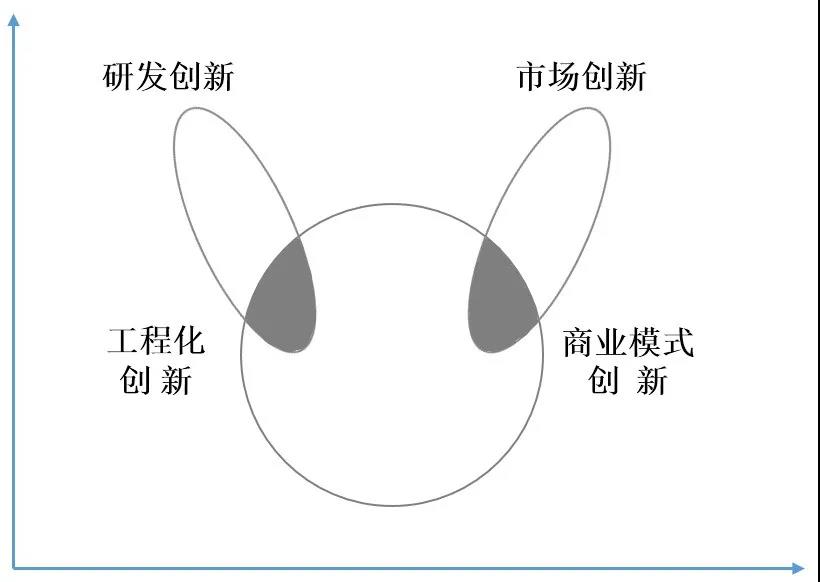

Figure 1Gray innovative rabbit ear curve

Gray scale innovation has taken the biggest threshold of international cooperation. The expansion of Japan and South Korea in Southeast Asia also adopted the mode of "domestic design and Southeast Asian manufacturing", which played a great role in helping the local economy take off and produced many innovations. However, all these are not as outstanding as made in China. However, it is not easy to recognize the contribution of made in China.

The American industry has always praised "source innovation" and believes that this is what a country should promote. In fact, this is also an important scientific and technological innovation thinking that has dominated the United States since World War II. Scholar Vannevar Bush is regarded as the founder of the "pipeline model" of American innovation. He had a profound impact on the government as early as the Roosevelt era. The "pipeline model", as its name implies, describes the relationship between invention and innovation as a pipeline connected up and down. The government only needs to invest in basic research at the upper end of the pipeline, then these investments will produce a large number of innovation seeds; As long as entrepreneurs downstream of the pipeline catch these seeds, continue R & D cultivation, and do a good job in design and production, they will produce a large number of innovative achievements. The gist of this model is to do a good job in basic research, do a good job in source innovation, and grasp the origin of major breakthrough inventions, which can produce enough wealth. This is a typical idea of "technical supply". This view actually ignores the contribution of "gray innovation". It basically turns a blind eye to the innovation generated by the interaction between manufacturing and research and design. Now, the United States has begun to deny this model established and respected by itself, and instead believes that if "design and manufacturing" can be together, it seems easier for innovation to occur.

Case: amplification effect of gray innovation

German vensys Energy Co., Ltd. (hereinafter referred to as vensys), founded in 2000 and located in a small town in Germany, is one of the pioneers in the development of large-scale direct drive permanent magnet wind turbines in the world. This is a "school run factory" enterprise founded by professors of sarrbruken, a local university, using research results. Starting from the development of 600 kW direct drive permanent magnet technology, it has gradually developed to a series of products such as 1.2 MW, 1.5 MW and 2.5 MW, and has obtained many patents and pioneering technologies. It can be said that vensys is the source innovation with the golden key. Because the direct drive permanent magnet technology uses the wind wheel to directly drive the permanent magnet generator, the structure is simple and optimized, the output power is greater at low speed, the efficiency is higher, and the degree of electronization is high. The high fault and high cost gearbox necessary for the doubly fed fan is omitted, which greatly reduces the maintenance cost and improves the power generation efficiency by more than 5%. However, in 2000, the design and manufacturing technology of large permanent magnet motor was still blank, and the cost of full power converter was still high. Therefore, although the permanent magnet direct drive technology is promising, those companies in the market leading position still adhere to the doubly fed scheme with gearbox for the megawatt technology route.

Due to the lack of due manufacturing and market development capabilities, there are not many "experimental fields" for new technologies. In the highly competitive European wind power market, vensys has been struggling to survive. Vensys's main revenue source is technology transformation and technology royalty, while the sales revenue of complete machines and parts is very small.

This means that from the perspective of value chain, although vensys focuses on R & D, it belongs to the "source" of manufacturing innovation. However, if there is no manufacturing site as fertile soil, even if the upstream R & D technology is no longer leading, it can not really enter the innovation cycle.

It was not until 2003 that the intervention of Jinfeng company, China's largest fan manufacturer, changed this situation. Through the localization of 600 kW / 750 kW units, Jinfeng company has reached a certain level in product manufacturing and technology accumulation. In the key stage of Jinfeng's development, we saw this epoch-making technology and began to cooperate with vensys in direct drive permanent magnet technology in 2003. Germany's innovative technology and China's manufacturing capacity have produced a positive integration effect, and both sides have achieved great success in the market.

Integrating with foreign R & D and design is a long tradition of Jinfeng. As one of the earliest enterprises to pioneer China's wind power industry, Jinfeng began to intervene in the field of wind power manufacturing in the 1990s, mainly through the purchase of production license technology, the introduction of mature wind power technology, and the digestion and absorption of the introduced technology to realize the localization of key parts and the mass production of units, which laid a solid foundation for China's wind power industrialization. In the process of digesting and absorbing the introduced technology, Jinfeng pays special attention to the use of foreign advanced design software. It is not only willing to spend a lot of money to buy, but also sends key technical personnel abroad for training many times. In this process, Goldwind purchased a large number of design software, including complete machine and load design, mechanical design and simulation analysis software, which was very rare at that time. Learning the theoretical knowledge behind these design software enables Jinfeng technicians to digest and understand the logic behind the software, so as to understand the design of the unit more comprehensively. In addition, Goldwind also actively engaged in the construction of wind power technical standard system. From the beginning, it referred to Germany's advanced industrial standards and certification specifications to standardize domestic parts with high standards and strict requirements.

After the initial introduction, Jin Feng felt that there was room for improvement in the design concept behind these standards, so he decided to adopt the method of joint innovation for the outside. The industrial foundation of the west is a kind of soil with balanced soil. Whether it is cooperation with schools, research units or parts manufacturers, it has strong integrity and mutual support accuracy. Even if the achievements made by foreign universities are directly matched with finite element analysis and experimental data, they can be put into application after a little engineering modification. The engineering trend of Western R & D is obvious, and this is where domestic institutes are relatively weak.

At that time, the sales of wind power equipment of Goldwind were mainly concentrated in the low-end market with small capacity below 1.0 MW, while the medium and high-end fan market with more than 1.5 MW was occupied by multinational companies such as GE wind power and Mitsubishi Heavy Industries for a long time. In this case, Goldwind decided to jointly develop 1.2 MW direct drive wind turbine with vensys. However, although the 1.2 MW prototype operated in Dabancheng wind farm has passed the certification of German windtest testing agency, the power generation performance of the prototype has reached the most advanced international level. However, in the initial stage, due to the lack of technical running in and supply capacity of the two companies, mass production was delayed, and a large number of orders in hand could not be delivered on time.

In order to reverse this passive adverse situation, in April 2008, Jinfeng, which was soon listed, spent 41.2 million euros to buy 70% of the equity of vensys company, holding the intellectual property rights of direct drive permanent magnet technology in its own hands. However, the successful acquisition of vensys is entirely due to the five-year cooperation between the two sides. At the beginning of the acquisition, Goldwind was not the highest bidder, and two other strong competitors, American GE and Goldman Sachs, were also eyeing it. Renk, CEO of vensys, who finally chose Jinfeng, explained, "vensys is just an R & D team. Compared with pure capital investment, vensys hopes to see its own technology landing and recognized by the market. It is better to see the future of long-term cooperation and development with Jinfeng than choosing Jinfeng to acquire vensys". The long-term joint design and manufacturing of the two also greatly reduces the running in cost of the M & a process. After the acquisition, the German Goldwind wind wind energy subsidiary simply moved to the city where vensys is located to work with vensys employees. China and Germany send engineers to each other to provide every opportunity to promote exchanges between the two sides of M & A. From the first few days of meetings and exchanges, to several months of posting and rotation, and then to one year, two years or even many years of resident in the other company, the two teams realized the unity of R & D ideas and the integration of development tools and design methods in the process of business cooperation, effectively improving the work effect and output efficiency of product R & D. Meanwhile, in the process of business integration, Germany has gradually accepted the same value orientation and customer orientation. Overtime is sometimes accepted by the German side. This is the result of the integration and influence of eastern and Western cultures.

One of the biggest features of made in China is its creativity. How to combine the rich creativity with the rigorous thinking and craftsman spirit of German design is a great test of the wisdom of both sides. After the collision between Jinfeng and vensys was accepted by both parties, the product design began to become very standardized. For example, for the design upgrade of the protective layer of magnetic steel, the Goldwind R & D and process design team drew lessons from the relevant production processes of blades and quickly formed a vacuum coating on the surface of magnetic steel to improve the production efficiency and process effect of the original protective design. After learning this idea, the vensys team carefully compared the technical characteristics of relevant processes in blade manufacturing and magnetic steel protection, Under the condition that the design principle is correct, the theoretical analysis, simulation and small sample test are carried out in detail for many links such as materials, tooling, operation steps and production beat. After verification and further optimization in domestic workshops, both parties finally confirmed the new protective layer design and process scheme.

Subsequently, the test of both sides entered the second stage, that is, the link of industrialization. China's industrial supporting facilities are relatively complete. Reform and opening up has introduced many international standards and international equipment, which can soon form an industrial chain or supply chain system that can quickly enter the market. The development of supply chain is not only a huge innovation, but also an innovation that is easy to be ignored. In fact, what we get from Germany is a rigid standard. How to turn the standard into tooling and how to turn it into technology requires too much re creation.

For example, the rolling dipping process is generally used to dip the motor. There is insulating paint in an oil tank, on which a shaft is erected to rotate the motor, just like Beijing converter roast duck. However, for the large-size permanent magnet direct drive motor designed by vensys, this method has low production efficiency, high material cost, uneven paint surface, and quality defects in the production process will affect the insulation life of the motor. However, German vensys said it could do nothing, because from the design side, it could only come to this step. Jinfeng engineer held this large-scale design drawing and repeatedly negotiated with the motor manufacturer, and finally decided to invest in the construction of a large-scale vacuum paint dipping equipment to allow the whole motor stator to be vacuum painted. Due to the use of negative pressure, the insulating paint is easier to penetrate into the interior of the motor, making the insulation effect very good. After dipping, the routine 100% immersion test shall be carried out.

This customized manufacturing around design completely solves the large-scale production process at the field end. Around the emergence of a large number of professional practical knowledge at the manufacturing end, that is, the so-called "black hand" innovation, a pair of black hands who always touch the oil in the workshop, so that the designer's genius idea can finally be realized.

The main bearing assembly of large direct drive unit is a very key process. In order to achieve the best use effect, the assembly clearance between the main shaft and the bearing should be as small as possible. From the tolerance fit of traditional manufacturing, in theory, to meet this design requirement, only the bearing clearance and the dimensional tolerance of the shaft can be reduced. But in practice, this is very uneconomical and almost impossible to achieve. How to find a way to reduce the cost and ensure the fit gap in the batch production stage? The problems of German designers are once again left to manufacturing engineers. At this time, Jinfeng and upstream bearing and spindle manufacturers jointly explore possible methods. Finally, the three parties decided to replace "spatial accuracy" with "time difference". The spindle factory first obtains the clearance data provided by the bearing in advance, and then the bearing manufacturer starts mass production. Within the scope of this supply cycle, the spindle factory starts fine machining to make its size reach a specific value. An ingenious coordinated battle began. At that time, when the supply of bearings was extremely tight, the spindle manufacturing process was adjusted and improved overnight, and finally every bearing obtained from the manufacturer entered the assembly stage smoothly, meeting the design requirements without greatly increasing the difficulty of parts processing. The precision of upstream R & D designers and downstream precision assembly echo each other, and jointly show the exquisite beauty of design and engineering.

Due to China's large geographical span and diversified geological features, various environments such as high temperature area, low humidity area, high altitude area, inland wind sand area and offshore salt fog area will bring different challenges to wind turbines. There are many flat lands in Europe. Except for the Alps with an average altitude of 3000 meters, it is difficult to find too many high mountains in other regions. In China, many wind farms are in the Northwest with an altitude of 3000 ~ 4000 meters. Similar to Guangdong and Hainan, there is almost no high salt, high tide and wet weather in Europe. In Northeast China, a wind farm with a temperature of minus 42 ℃ also exists, while European designers sometimes think that not all businesses can be done. It is difficult to achieve, not to mention minus 42 ℃ or below minus 25 ℃. However, this is China's unique market. If you don't conquer it, no one will do it. These complex and changeable working conditions provide a steady stream of application scenarios for the research and development of vensys. This also means that "designed in Germany and made in China" has entered the second round of innovation stage.

Due to the low speed, it is difficult to measure the speed of direct drive unit. The traditional method of using encoder to obtain the speed through frequency voltage conversion is costly and prone to failure. More importantly, this method is also effective for 1.5 MW motors, but it is no longer applicable for higher power 2.5 MW motors. To solve this problem, Goldwind R & D engineers developed a new algorithm to extract the characteristic information of three-phase chord wave intersection angle of a single generator winding, so as to realize the full digital and accurate measurement of speed without calibration and verification. This idea excited the design engineers of German vensys. Based on this technology, combined with model prediction, contactless angle measurement of generator and wind turbine can be realized, and the cost is greatly reduced.

With the help of capital as a link, the gray-scale innovation of their cooperation has entered a fast track. For Jinfeng, its sales volume in the international market was very small before 2008. After the acquisition of vensys, Jinfeng can use vensys's high-end German manufacturing brand to enter the European and American markets. Goldwind immediately established a subsidiary manufacturing variable current and pitch systems, which belongs to the production subsidiary of vensys. Through this subsidiary, it produces vensys high-end German manufacturing brand, taking this as a breakthrough to enter the German fan manufacturing market. Vensys brand focuses on the European and American markets, while Jinfeng focuses on China, Asia and Africa, and implements the "dual brand strategy". Vensys is not only the key R & D platform of Jinfeng, but also began to assume the function of European marketing subject.

Compared with vensys, Jinfeng has cost advantages in manufacturing, while vensys has technical advantages in R & D. This is a typical successful case of gray innovation. For the design of vensys, only Jinfeng and only in China can find matching parts with appropriate cost, improve them and feed back the results to vensys. In this way, vensys's design advantages are combined with Jinfeng's advantages in manufacturing and process. The advantages of industrialization make Jinfeng a strong backing for vensys. By 2015, Goldwind had more than 4600 new installed capacity and more than 7.8gw new installed capacity, becoming the world's largest wind turbine manufacturer, and increasing the share of direct drive units in the global wind power market to more than 20%. The scale of vensys is also developing, and it has started to have two production bases in Germany, with an annual turnover of about 100 million euros.

The joint design and R & D of Jinfeng and vensys will carry forward the direct drive permanent magnet technology. As a typical European R & D company, vensys attaches great importance to its original "source innovation", and has patented the key technology of direct drive permanent magnet to achieve the maximum protection effect with limited investment. While Jinfeng continues to increase its investment in intellectual property rights and protect foreign intellectual property rights, it establishes an effective patent protection group through follow-up technological innovation and continuous patent development. In addition to protecting the core technology of permanent magnet direct drive in a larger region, it also effectively protects "black hand" innovations such as tooling process methods. At the same time, Goldwind has also opened the door to gray-scale innovation, established Goldwind R & D bases in Denmark, Germany and Australia, successively cooperated with Tsinghua University and other universities, established a multi-channel innovative R & D system, and obtained the design and manufacturing experience of key components such as electronic control system, converter and pitch system.

From loose cooperation to in-depth innovation, capital plays an important catalytic role. However, at the beginning, direct drive permanent magnet power generation was a non mainstream technology, its industrial chain was incomplete, and there were few corresponding parts suppliers. Jinfeng is well versed in the way of cooperation in the industrial chain and forms the innovation of various mechanisms. Goldwind has taken unusual measures to build an industrial platform and jointly design parts with upstream suppliers to support suppliers. In order to attract the world's largest blade supplier - Danish LM company, Jinfeng even unilaterally funded the construction of plants for LM company in Xinjiang, and the locally matched LM high-quality blades have played an important role in the development of Jinfeng. In the production and manufacturing of converter insulated gate to pole transistor (IGBT) module, Jinfeng also strengthened the technical cooperation with Infineon and strengthened the technical reserve of high-end parts and modules.

epilogue

The sudden COVID-19 has caused serious disaster in the world. The supply chain of manufacturing industry is also greatly affected, and the global manufacturing industry is facing great challenges. The relationship between manufacturing and innovation has never been shown more clearly than at present - this is an amazing achievement shown by made in China in the process of global industry moving towards professional division of labor. For manufacturing innovation, a longer value chain cycle is needed to identify the value.

Not only "source innovation" and "design innovation" are shining innovations. At the factory site, made in China has also made brilliant innovation achievements through engineering combination with source innovation. For example, excellent manufacturing enterprises such as Xinjiang Jinfeng and Suzhou Bozhong have extended the huge market value of source innovation and realized the perfect combination of basic principles and market application through the innovation at the manufacturing end. This is an exploration of the perfection of China's manufacturing innovation chain. After reshaping and even reengineering the process of knowledge crystallization, it makes a great contribution to innovation.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853