-

- RF Series

- Connector&plug-in unit

- Plug-in unit

- SD card holder

- SIM card holder

- Thimble /wire protector

- Crimping terminal

- Waterproof joint

- 短路帽/跳线帽

- 压线端子胶壳

- 屏蔽夹

- Waterproof and dustproof terminal

- Industrial&automotive&military

发布时间:2021-12-31作者来源:金航标浏览:2411

Speaking of“A number of emerging enterprises focusing on industrial Internet technology innovation are emerging,At the beginning of 2018, aii (China Industrial Internet industry alliance) released the statistical results: "according to preliminary statistics, China currently has 269 platform products";At the beginning of 2019, this number has increased sharply. For example, there are at least 5000 enterprises engaged in "industrial Internet" business in "enterprise search". The author assumes that only 20% are actually engaged in industrial Internet business, and there are more than 1000!

The government's advocacy, the enthusiasm of manufacturers, the hot speculation of the media, the boost of experts and the favor of capital have created the hot phenomenon of industrial Internet in China. More than 5000 participants signed up for the 2019 industrial Internet Summit. More than 5000 registered industrial Internet enterprises and more than 5000 industrial Internet Summit. From these "two 5000" figures, we can see that Chinese people pay attention to the industrial Internet.

It is very different from the intelligent manufacturing started a few years ago. This time, many enterprises are competing to be industrial Internet participants, and all participants are running fast. It seems that no one knows exactly where the destination is. Especially after Ge, which once led, suddenly fell out of the track, this large group of participants seem to have no intention of stopping. So sardine sardine is sardine, which is often mentioned in SoS, which is a phenomenon that is always catching up with the sardines. The sardines are tired or eaten by big fish. Then another sardine has the responsibility of the leader fish, but it is not the same direction. One after another, relay and emerge. In fact, it is uncertain where to swim.

The development of industrial Internet is a country's strategic decision, and its key, necessity and many benefits to industrial transformation must have been taken into account; At the same time, various problems on the road of developing industrial Internet should and must be considered. Otherwise, the result of rushing into mass action is to rush down.

The author believes that there are still many problems to be considered in the development of industrial Internet / industrial Internet platform. At least five Mount Everest are waiting for participants to climb.

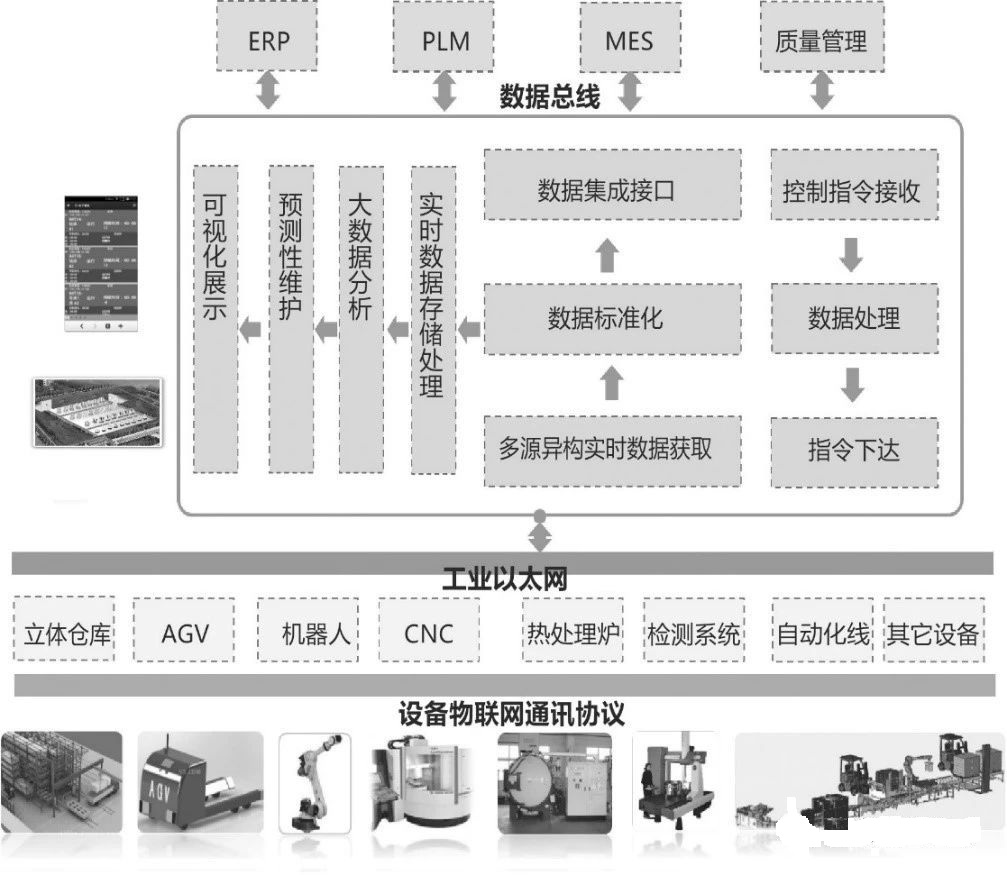

Although both the industrial Internet and the consumer Internet are in the name of "Internet", they are actually very different networks because of the different "terminals" connected. The consumer / social Internet uses the Internet and connects terminals such as computers, tablets and mobile phones. As long as they comply with the standard internet protocol, they can be "plug-in" connected to each other, and they are basically connected at the application level. The industrial Internet is mainly based on Industrial Ethernet, which is connected with a variety of industrial equipment. When industrial Ethernet is used for industrial control, it is reflected in the application layer of real-time communication, objects for system configuration and application protocols of engineering models, only in real-time, Industrial Ethernet is required to respond within an accurately predictable time range (such as milliseconds), while commercial networks do not have this harsh requirement. Real time, anti-interference and high reliability are the basic requirements of industrial equipment networking. Therefore, the enterprise equipment Internet of things (the basic network of industrial Internet) is adopted in the enterprise workshop, as shown in Figure 1.

In the development process of various industrial equipment manufacturers, in order to better adapt to the complex working environment of the factory and reflect the characteristics of the equipment, different manufacturers use different fieldbuses, and different equipment communication protocols are required between different equipment to reliably transmit data. Therefore, until today, there is no global unified application layer protocol.

Experts who really do the Internet of things of enterprise equipment know that the connection between different industrial equipment is an extremely complex problem. Various industrial equipment with different periods, different brands and different buses, such as machine toolsHeat treatment equipment, automatic production line, flexible production line, special machine equipment, AGV, 3D printing equipment, injection molding machineMeasuring instruments, reactors, sensors, instruments, robots and even wearable devices all have data communication protocols in different formats. Each enterprise producing equipment develops the equipment interface protocol first according to the functional requirements of its own equipment. Whether it needs to be compatible with the equipment of other enterprises is not the first consideration.

According to Zheng Bingquan, a senior expert of Asian control company who has been engaged in equipment networking for more than 20 years, there is less workload in the connection and development of new equipment. To connect many existing equipment of the enterprise and make all equipment communicate with each other barrier free, at least 5000 kinds of communication protocols are required. Moreover, this is a long process of practice, precipitation and accumulation - sometimes the devices with two different protocols seem to be connected, and even work stably for many days, but they suddenly don't work after a period of time, because a special format of the communication protocol was not considered in the past and happened not to be used, but now it happens to be used.

Zhu Duoxian, the first author of Ji · Zhi and chairman of Languang innovation, believes that although the trend of equipment communication protocols is towards standardization, the major giants have not yet reached an agreement under the constraints of interest pattern. In general, Germany prefers OPC UA protocol for industrial equipment integration, while North America and Japan prefer mtconnect protocol. In any case, if you don't understand the more than 5000 device communication protocols, you will be greatly limited in terms of device interconnection.

As the saying goes, every line is like a mountain. One of the greatest achievements of the industrial revolution is industry / professional segmentation. Different industries / specialties have different subdivision technologies and unique expertise. The most common welding in the manufacturing "connection technology" can have seven or eight hundred different processes; A high-voltage transmission line can also be described by hundreds of different models; Not to mention the super comprehensive complexity that is difficult to decompose in complex products, such as civil aircraft, aeroengines, nuclear submarines, aircraft carriers and shipborne aircraft; There are also precision robot reducers, high-end chips and EUV lithography machines for making chips that we do not yet master in high-tech.

At present, there is no industrial Internet platform in China that supports the subdivision of specialties and the coverage of the whole industry. Assuming that these industrial Internet platforms already exist, there will still be "barriers" and "gaps" of various industrial knowledge: that is, a mature electronic product industrial Internet platform is unlikely to be adopted by aviation enterprises; No matter how good a medical equipment industrial Internet platform is, it is unlikely to be adopted by construction machinery enterprises, because there are no industry / professional application scenarios, professional knowledge and industrial apps supporting these scenarios on the "others' home" platform. For example, Ge digital's "three-step" development strategy "Ge for GE, ge for customers and Ge for world" is actually very pragmatic. But logically, the first two steps are correct, but this third step steps on the red line of "knowledge barrier". Where is "for world" so easy to step out? I'm afraid important steps such as "for other industries" and "for USA" have been omitted, as well as long-term precipitation and repeated grinding necessary to verify and optimize these important steps. The step that GE # digital takes to go out is the short board that leads to the suspension of its business - knowledge barrier.

So far, the author has not heard that any enterprise is willing to put its R & D knowledge, experience and skills and digital model of products on the industrial Internet platform of "others' home". Small enterprises dare not do it because they are worried about the leakage of technical know-how, and large enterprises simply develop their own platform because they are worried about the non protection of intellectual property rights.

If it is an industrial Internet platform developed by peers with professional counterpart industrial app applications, it is reasonable to say that an industrial Internet platform with fully available technology should be optional. However, from the perspective of the boss of the enterprise, the more peers, the more they fear and stay away. The barrier in their heart may be higher than Everest. Imagine how a automobile enterprise can put its automobile R & D model data on the industrial Internet platform developed by B automobile enterprise? Don't even think about it! There are too many reasons for horizontal competition, trade secrets, ownership of data property rights and protection of data security (not being illegally read, modified, copied and used). In short, enterprises have taboos. Enterprises hold a rather conservative attitude towards the sharing of R & D, production and operation data on the industrial Internet platform - bosses often ask: is this good for my enterprise—— No answer. Therefore, now slightly powerful enterprises are either in a wait-and-see state or simply invest in developing an industrial Internet platform. This is also one of the reasons why domestic industrial Internet enterprises have sprung up.

For national defense industry enterprises, confidentiality is the primary issue. The same is true for other enterprises that undertake the task of national defense and military industry research and development. Keep it a secret. Any graphic, data, technical archives and other documents related to the development task must be physically isolated from the network. Therefore, enterprises involved in the research and development of national defense and military industrial models will never be able to access the consumer Internet, and it is expected that they will not be able to access the industrial Internet (except the internal network isolated by the enterprise). At the same time, according to the regulations of relevant government departments, secret related enterprises cannot carry out cloud related business activities, even enterprise private cloud.

Confidentiality is the obligation of secret related enterprises stipulated by law. It is the primary thing that must be observed and takes precedence over all other things. It is an untouchable high-voltage line. This is almost a Everest on which secret related enterprises cannot climb and surpass.

I sometimes ask myself such a question (I have also asked several industrial Internet enterprises): there are so many domestic industrial Internet platforms. Can these "platforms" be connected with each other? The author's answer is "no connection". So, the problem comes! There are hundreds (maybe thousands in the future) of industrial Internet platforms that have integrated a group of customers, but they "don't communicate with each other". A familiar scene emerged in front of the author:

The early popularization of manufacturing informatization in China resulted in numerous "Thousand Island Lake" and "chimney" enterprise informatization integration projects. The result is that it is difficult to integrate between informatization software of different brands and functions, between informatization software and physical system, and between Informatization Systems of different enterprises!

Today's industrial Internet platform still seems to be unable to escape this stereotype. If this goes on, the separation of the princes of the industrial Internet platform is an inevitable result. It is unknown when the Warring States era of the industrial Internet platform will finally end. From the perspective of difficult interconnection, the industrial Internet can also see the biggest difference from the consumer Internet——The consumer Internet is an international Internet that connects and exchanges data all over the world. The industrial Internet is actually a local (non national) LAN connected by strong parties in the industry (not the whole industry) and conditional access to data.

What kind of industrial Internet will develop into is a brain burning problem. I hope there will be an answer in a few years.

Summary

Industrial Internet is developing rapidly in China, with high attention and hot market. The competent administrative department believes that "the innovation and development of industrial Internet has entered the fast lane", and the government, experts, manufacturers and capital have become "fast hot", but the real user of industrial Internet - enterprises, for various reasons, seems to be still "slow hot", and it will take some time to really pay for the industrial Internet.

Industrial Internet is the key support to realize the high-quality development of industrial economy. We must seize and grasp this rare historical opportunity. However, for the problems that may be encountered on the road of industrial Internet development, we must consider in advance, deploy research in advance and formulate preventive measures in advance. Don't be like the wayward and wild development of "sharing bicycles". The competent authorities don't have any layout and disposal plans for potential problems. They are busy thinking about how to solve problems when various problems burst out.

Industrial Internet has a long way to go, broad prospects and promising opportunities. But there are five Everest, so it's better to make full use of the plan.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853